Decompression combined air-gap membrane distillation method and device thereof

A decompression membrane distillation, membrane distillation technology, applied in pervaporation, heating water/sewage treatment, energy waste water treatment and other directions, can solve the problem of low flux of membrane distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

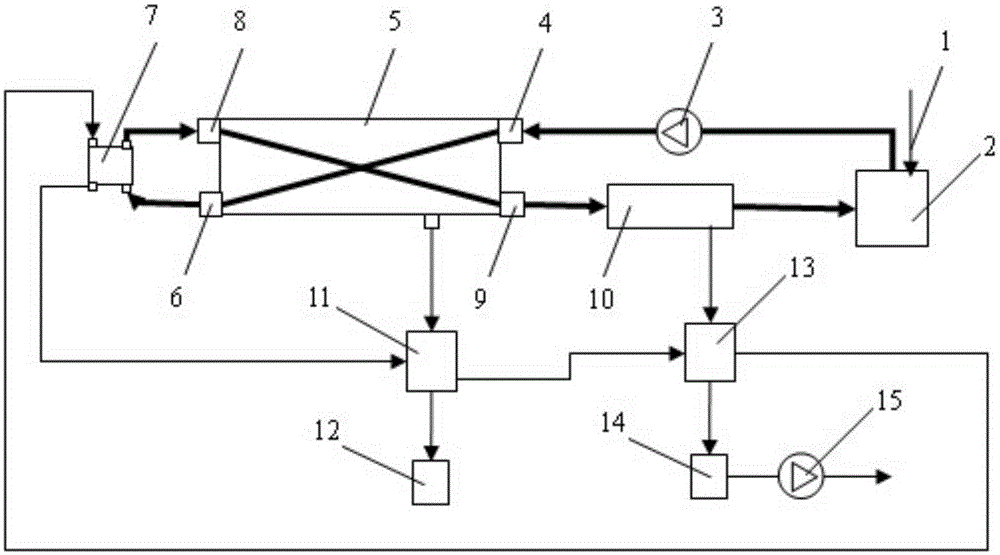

[0016] according to figure 1 , to further illustrate the method and device for decompression combined air-gap membrane distillation of the present invention.

[0017] The feed liquid that is supplemented and heated by the heat pump 7 enters the tube side of the hollow fiber hydrophobic membrane from the inlet 8 of the air-gap membrane distillation assembly 5, and evaporates. Outflow, outlet temperature is 50 to 80 ℃, enters vacuum membrane distillation assembly 10, under the action of vacuum pump, carries out vacuum membrane distillation, unevaporated material liquid is cooled, and temperature is 40 to 60 ℃, then flows into circulating water tank (raw water tank ) 2, after merging with newly replenished raw water 1, it is sent into the inlet 4 of the air-gap membrane distillation assembly 5 by the circulation pump 3, and enters the heat exchange tube. The pipe outlet 6 enters the heat pump 7 to continue supplementing heat and carry out the next cycle.

[0018] The condensed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com