Correction method and device for surface shape of polishing disk in full-caliber polishing

A surface shape and polishing disc technology, which is applied in the direction of abrasive surface adjustment devices, grinding/polishing equipment, grinding machine parts, etc., can solve problems such as difficult to obtain a flat surface, achieve good correction control certainty, and facilitate correction , the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

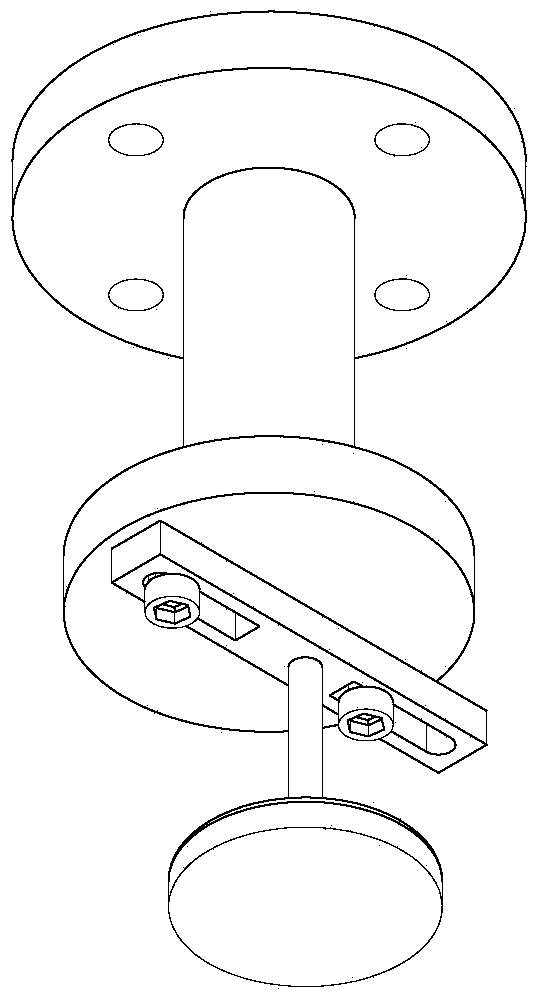

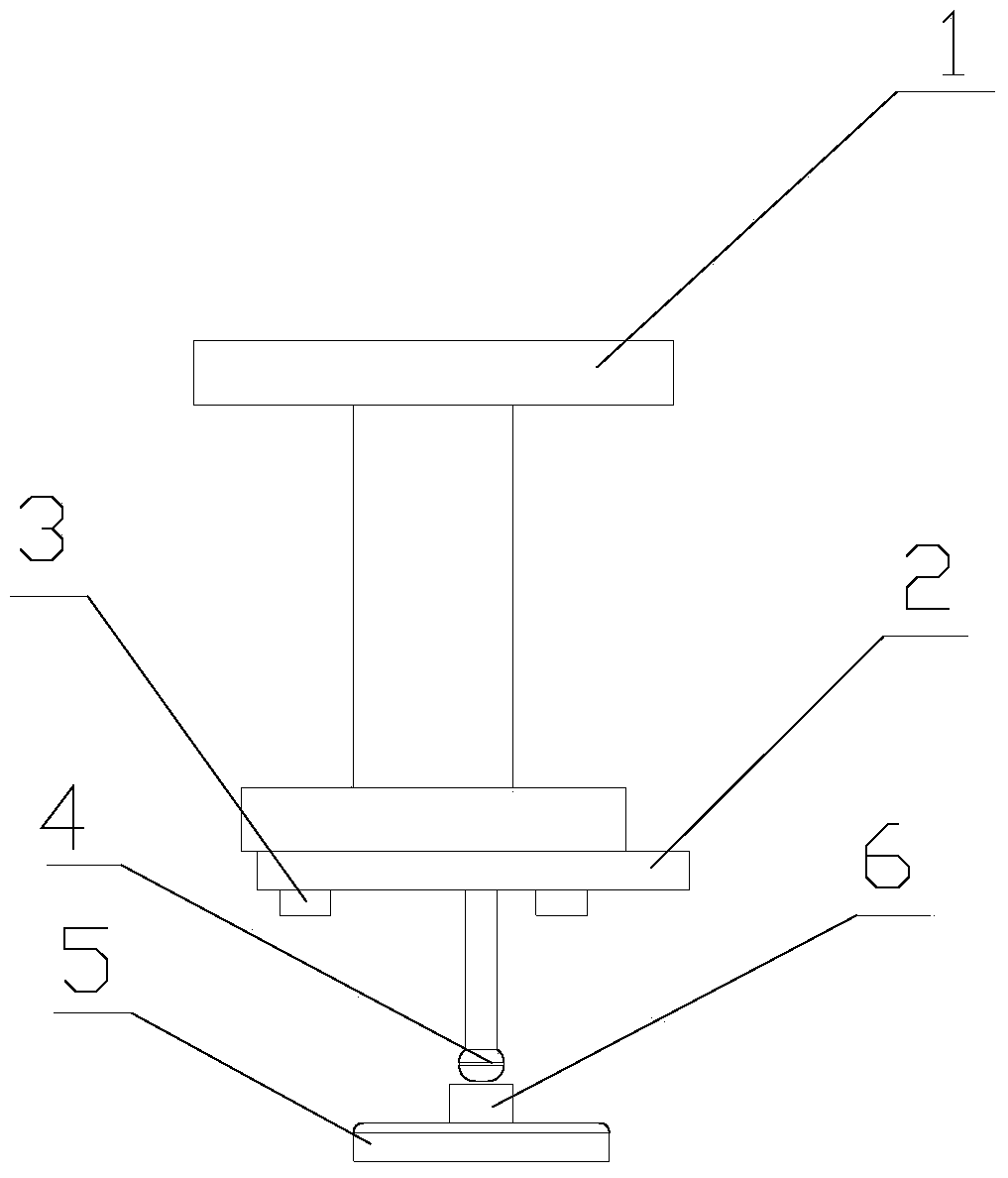

[0022] Such as figure 1 and figure 2 As shown, the correction device of the present invention includes a main shaft connection frame 1, a T-shaped eccentric adjustment block 2 is arranged at the lower end of the main shaft connection frame 1, a ball thimble 4 is arranged at the lower end of the eccentric adjustment block 2, and a small tool is arranged at the lower end of the ball thimble 4. 5. A ball groove 6 is provided on the upper surface of the small tool 5, and the ball groove 6 is mated with the ball thimble 4.

[0023] The above-mentioned eccentric adjustment block 2 can be fixed on the main shaft connection frame 1 by screws 3, and the rotation axis of the eccentric adjustment block 2 does not coincide with the rotation axis of the main shaft connection frame 1, and the eccentric adjustment block 2 is used to adjust the rotation eccentricity of the small tool 5 ; During work, the main shaft connecting frame 1 can be fixed on the workpiece shaft of the polishing mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com