Tar wastewater treatment method

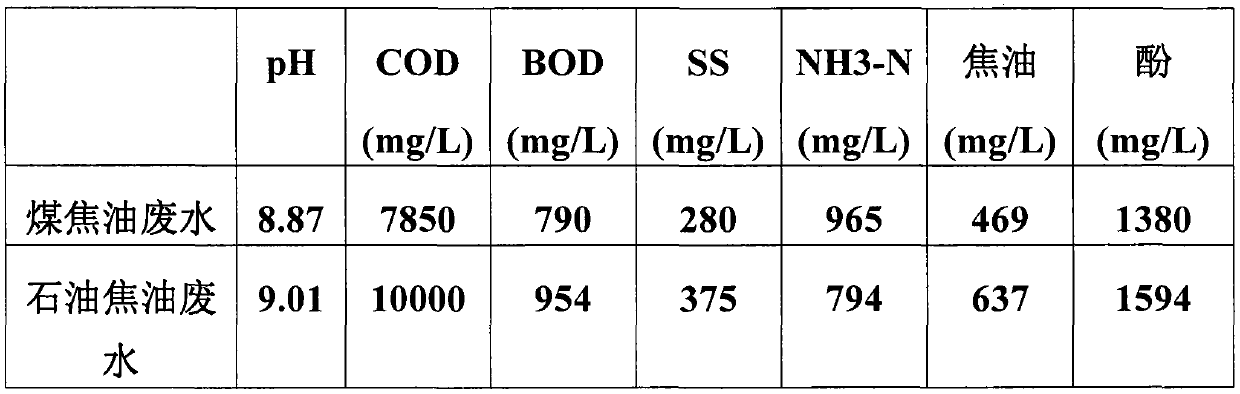

A waste water treatment, tar technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as poor waste water treatment effect and low tar removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Filter 14L of thick black coal tar wastewater with a 50-80 mesh screen to remove solids, add 0.4g of polyoxyethylene polyoxypropylene stearyl ether and 1L of simethicone to the tar wastewater, mix evenly, and let stand and separation to obtain the upper black simethicone layer and the lower turbid water layer I;

[0021] (2) Continuously inject nitrogen gas into the black simethicone oil layer, the flow rate of nitrogen gas is 30mL / min, at the same time heat the simethicone oil layer to 140-160°C for polycondensation for 7-8h, cool to 8°C and use 150-mesh screen filtration and separation to obtain solid primary polymer;

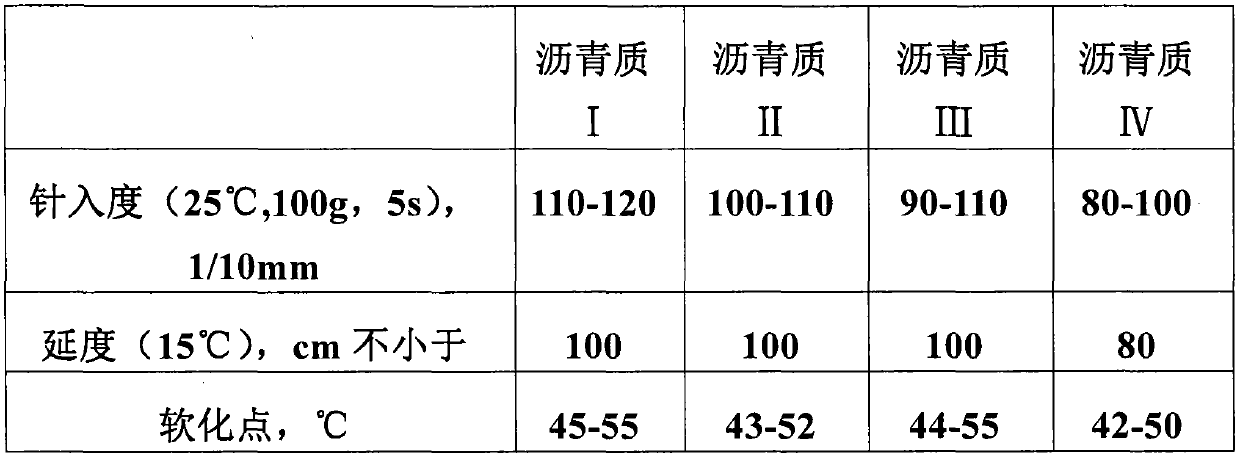

[0022] (3) Continue to polymerize the solid primary polymer at 360-380°C for 5-6h under the protection of nitrogen to obtain asphaltene I;

[0023] (4) Add hydrolytic bacteria and acid-producing bacteria to the water layer and mix them at 30°C for 9 hours, then treat with anaerobic bacteria and aerobic bacteria, finally settle out solids, and use ...

Embodiment 2

[0025] (1) Filter 30L of thick black coal tar wastewater with a 70-100 mesh screen to remove solids, add 0.75g of polyoxyethylene polyoxypropylene stearyl ether and 1L of simethicone to the tar wastewater, mix evenly, and let stand and separation to obtain the upper black simethicone oil layer and the lower turbid water layer II;

[0026] (2) Continuously feed nitrogen into the black dimethyl silicone oil layer, the flow rate of nitrogen gas is 60mL / min. 150-mesh screen filtration and separation to obtain solid primary polymer;

[0027] (3) Continue to polymerize the solid primary polymer at 300-350°C for 3-4h under the protection of nitrogen to obtain asphaltene II;

[0028] (4) Add hydrolytic bacteria and acid-producing bacteria to the water layer and mix and treat at 32°C for 8 hours, then treat with anaerobic bacteria and aerobic bacteria, finally settle out solids, and use a mixture of graphitized carbon black and activated carbon to absorb water Water body II is obtain...

Embodiment 3

[0030] (1) Filter 35L of thick black coal tar wastewater with a 60-90 mesh screen to remove solids, add 0.83g of polyoxyethylene polyoxypropylene stearyl ether and 1L of simethicone to the tar wastewater, mix evenly, and let stand and separation to obtain the upper black simethicone oil layer and the lower turbid water layer III;

[0031] (2) Continuously inject nitrogen gas into the black simethicone oil layer, the flow rate of nitrogen gas is 100mL / min, at the same time heat the simethicone oil layer to condense at 160-180°C for 5-6h, cool to 10°C and use 150-mesh screen filtration and separation to obtain solid primary polymer;

[0032] (3) Continue to polymerize the solid primary polymer at 380-400°C for 4-5h under the protection of nitrogen to obtain asphaltene III;

[0033] (4) Add hydrolytic bacteria and acid-producing bacteria to the water layer and mix them at 35°C for 7 hours, then treat with anaerobic bacteria and aerobic bacteria, finally settle out solids, and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com