A kind of medium and micro double hole hkust-1 material and its preparation method and application

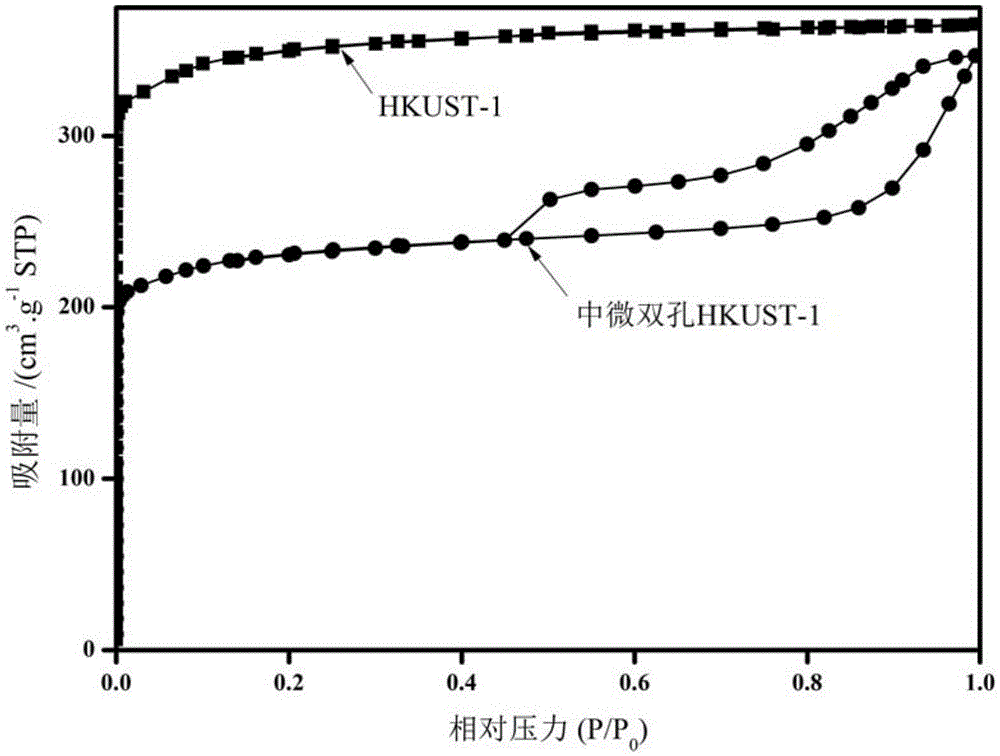

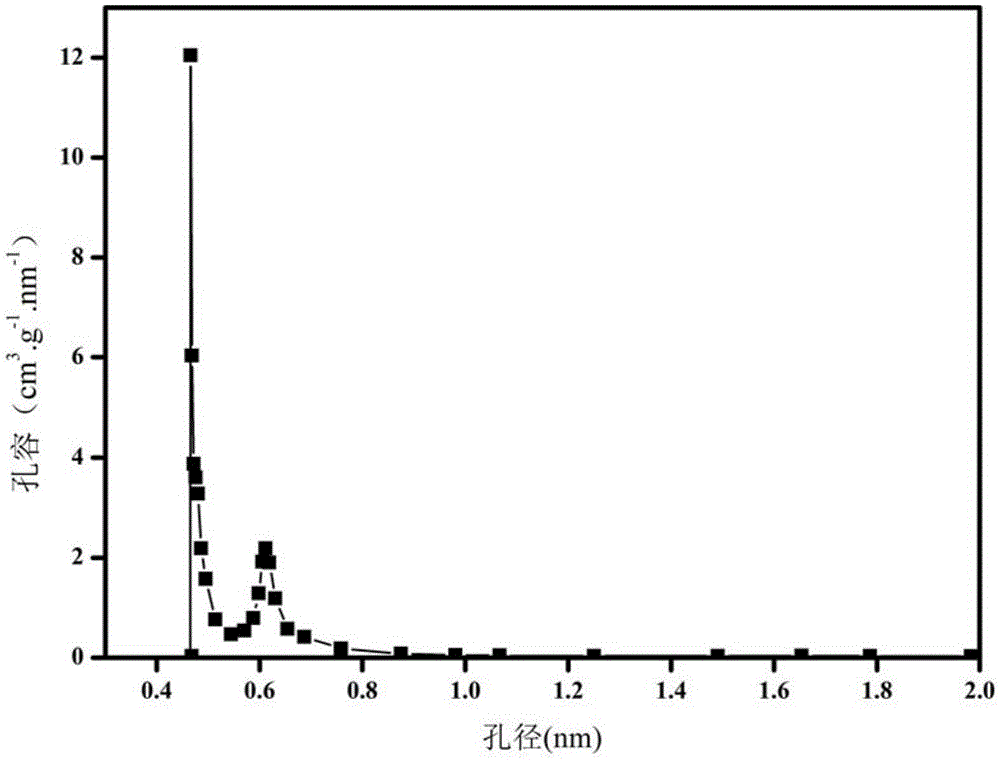

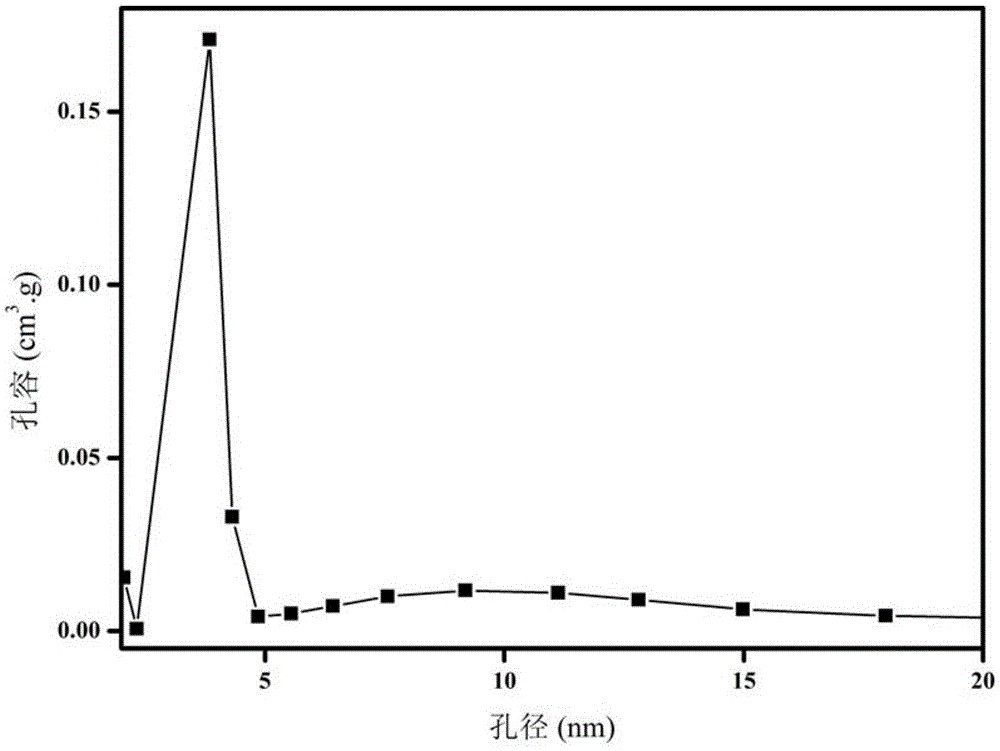

A HKUST-1, medium and micro-double hole technology, applied in chemical instruments and methods, other chemical processes, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of the wide application and synthesis cost of the long-ligand method increase and decrease of pore size, etc., to achieve the effect of rich micropore and mesopore structure, good crystal structure and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 1.068gCu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8mlDMF, 8ml ethanol and 8ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.46gH 3 BTC was dissolved in the same solvent formed by mixing 8mlDMF, 8ml ethanol and 8ml water, and stirred until it was completely dissolved to obtain a clear solution B; the clear solution B was added to the clear solution A, and stirred evenly to obtain a mixed solution; 0.197g3- APS was added to the mixed solution, and then stirred for 30 min; the mixed solution was transferred into a stainless steel autoclave for hydrothermal synthesis, and heated at 110 °C for 12 h; after cooling to room temperature, the product was filtered and vacuum-dried at 150 °C for 8 h; ℃ and soaked with ethanol for 4 times, each time for 12 hours; the product was filtered and vacuum-dried at 150 ℃ for 12 hours to prepare the sample B1 of medium and micro-porous HKUST-1 material.

Embodiment 2

[0041] Weigh 1.068gCu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8.5ml DMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.50gH 3 BTC was dissolved in the same solution formed by mixing 8.5mlDMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution B; the clear solution B was added to the clear solution A, and stirred evenly to obtain a mixed solution; Add 0.16g of 3-APS into the mixed solution, and then stir for 60min; transfer the mixed solution into a stainless steel autoclave for hydrothermal synthesis, and heat at 120°C for 8h; after cooling to room temperature, the product is filtered and vacuum-dried at 120°C for 15h; The product was soaked with ethanol at 150°C for 3 times, each time for 14h; the product was filtered and vacuum-dried at 140°C for 8h to prepare the sample B2 of medium-micro-porous HKUST-1 material.

Embodiment 3

[0043] Weigh 1.068gCu(NO 3 ) 2 .3H 2 O was dissolved in a solvent formed by mixing 8.5ml DMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution A; another 0.45gH 3 BTC was dissolved in the same solvent formed by mixing 8.5mlDMF, 8.5ml ethanol and 8.5ml water, and stirred until completely dissolved to obtain a clear solution B; the clear solution B was added to the clear solution A and stirred evenly to obtain a mixed solution; Add 0.32g of 3-APS into the mixed solution, and then stir for 50 minutes; transfer the mixed solution into a stainless steel autoclave for hydrothermal synthesis, and heat at 110°C for 10h; after cooling to room temperature, the product is filtered and vacuum-dried at 140°C for 15h; The product was soaked with ethanol at 120°C for 5 times, each time for 8h; the product was filtered and vacuum-dried at 120°C for 15h to prepare the sample B3 of medium-micro-porous HKUST-1 material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com