Hot mix asphalt pavement smoke suppressant and preparation method of smoke-suppressing asphalt

A technology of asphalt pavement and smoke suppressant, which is applied in the direction of building components, fibrous fillers, building insulation materials, etc., can solve the problems of complex preparation process, high cost, and different use effects, and achieve obvious technical and economic benefits and low cost Low, the effect of reducing the release of asphalt fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 97kg of SBS modified asphalt and 3kg of smoke suppressant.

[0027] The smoke suppressant includes 0.21kg of warm mixing agent KZW-50 (produced by Tianjin Kangzewei Technology Co., Ltd.) and 2.79kg of surface-modified aluminum hydroxide.

[0028] The process of aluminum hydroxide surface modification treatment is as follows: dry aluminum hydroxide at 100-130°C for 3 hours, then evenly spray silane ethanol aqueous solution on the surface of aluminum hydroxide, mix evenly, and obtain aluminum hydroxide after surface modification treatment; The volume ratio of silane, ethanol and water in the silane ethanol aqueous solution is 20:72:8.

[0029] Heat the asphalt to 100-130°C, then add warm mix agent, and stir for a certain time until uniform;

[0030] Then add aluminum hydroxide and stir for a certain period of time until the smoke-suppressing pitch is obtained uniformly.

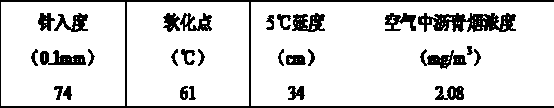

[0031] Tests have shown that the performance of the obtained smoke-suppressing asphalt is show...

Embodiment 2

[0035] Take 95kg of SBS modified asphalt and 5kg of smoke suppressant.

[0036] Among them, the smoke suppressant includes 0.45kg of warm mixing agent Evotherm TM 3G (produced by MeadWestvaco, USA) and 4.55kg of surface-modified aluminum hydroxide.

[0037] The process of aluminum hydroxide surface modification treatment is as follows: dry aluminum hydroxide at 100-130°C for 2 hours, then evenly spray silane ethanol aqueous solution on the surface of aluminum hydroxide, mix evenly, and obtain aluminum hydroxide after surface modification treatment; The volume ratio of silane, ethanol and water in the silane ethanol aqueous solution is: 20:72:8.

[0038]Heat the asphalt to 100-130°C, then add warm mix agent, and stir for a certain time until uniform;

[0039] Then add aluminum hydroxide and stir for a certain period of time until the smoke-suppressing pitch is obtained uniformly.

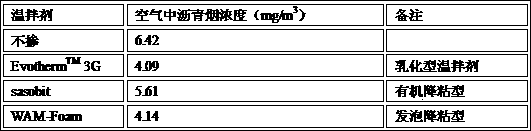

[0040] Tests have shown that the performance of the obtained smoke-suppressing asphalt is sho...

Embodiment 3

[0044] Take 96kg of SBS modified asphalt and 4kg of smoke suppressant.

[0045] The smoke suppressant includes 0.32kg of warm mixing agent LBW-1 (produced by Shijiazhuang Lubang Technology Co., Ltd.) and 3.68kg of surface-modified aluminum hydroxide.

[0046] The process of surface modification treatment of aluminum hydroxide is as follows: dry aluminum hydroxide at 100-130°C for 1 hour, then evenly spray silane ethanol aqueous solution on the surface of aluminum hydroxide, mix well, and obtain aluminum hydroxide after surface modification treatment; The volume ratio of silane, ethanol and water in the silane ethanol aqueous solution is: 20:72:8.

[0047] Heat the asphalt to 100-130°C, then add warm mix agent, and stir for a certain time until uniform;

[0048] Then add aluminum hydroxide and stir for a certain period of time until the smoke-suppressing pitch is obtained uniformly.

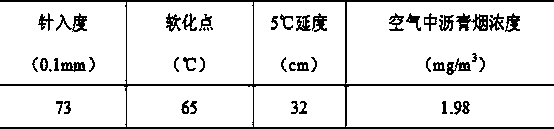

[0049] The test shows that the properties of the obtained smoke-suppressing asphalt are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com