Curved hpl plate for architectural decoration and manufacturing method thereof

A technology of architectural decoration and manufacturing method, which is applied in the direction of building structure, construction, chemical instruments and methods, etc., and can solve the problems that curved HPL boards cannot be popularized and applied in a wide range, the decorative effect is single, and customers are sighing. , to achieve the effect of mass production and application, rich colors, and overcoming empty drums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

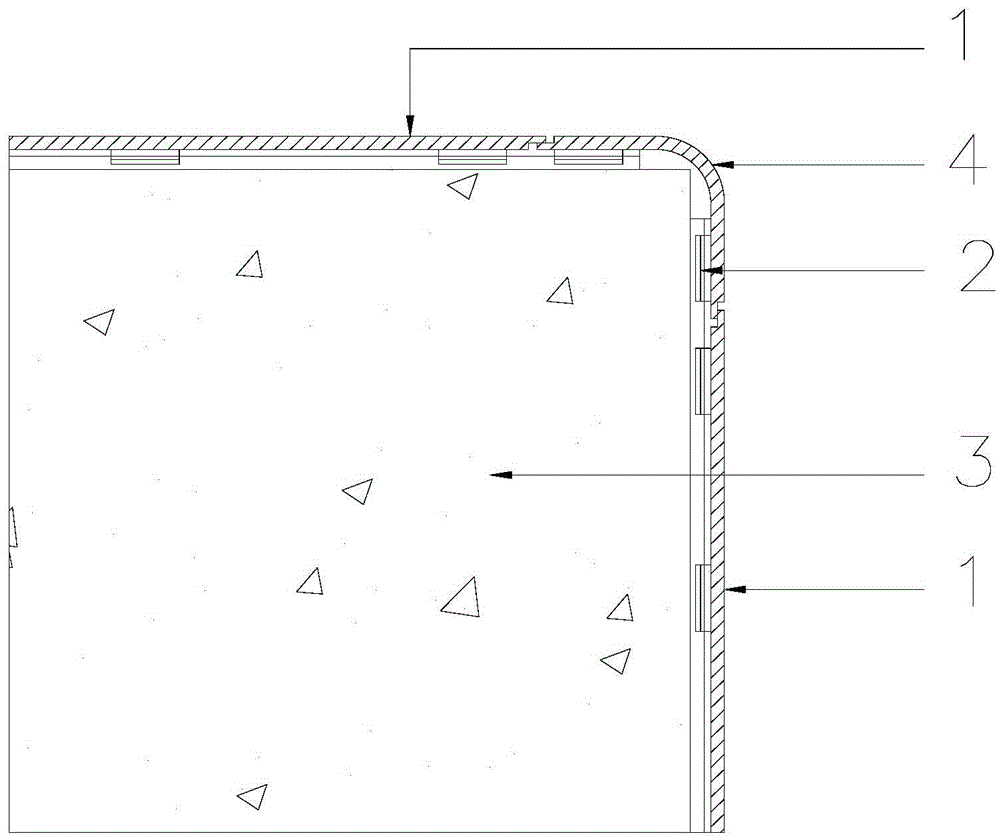

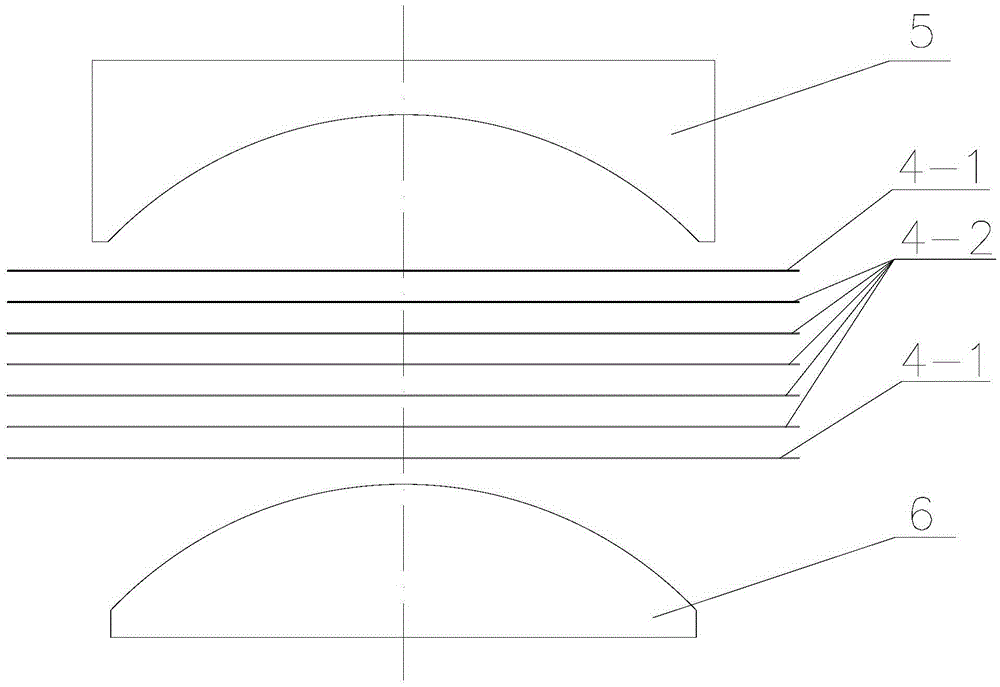

[0051] A kind of curved HPL plate 4 (such as figure 2 shown), such as image 3 As shown, the curved HPL board 4 includes multi-layer boards laminated layer by layer, the boards located on the upper layer and the lower layer are respectively fireproof boards 4-1, and between the two layers of fireproof boards is a multi-layer balance board 4-2, and the adjacent two layers of boards Paste them with black epoxy resin glue; each balance board has the same structure, and they are made of multi-layer kraft paper soaked in phenolic resin and pressed into shape; the thickness of the fireproof board is 1mm, and the thickness of the balance board is 1.2mm; the curved HPL board The bending radius ≥ 50mm.

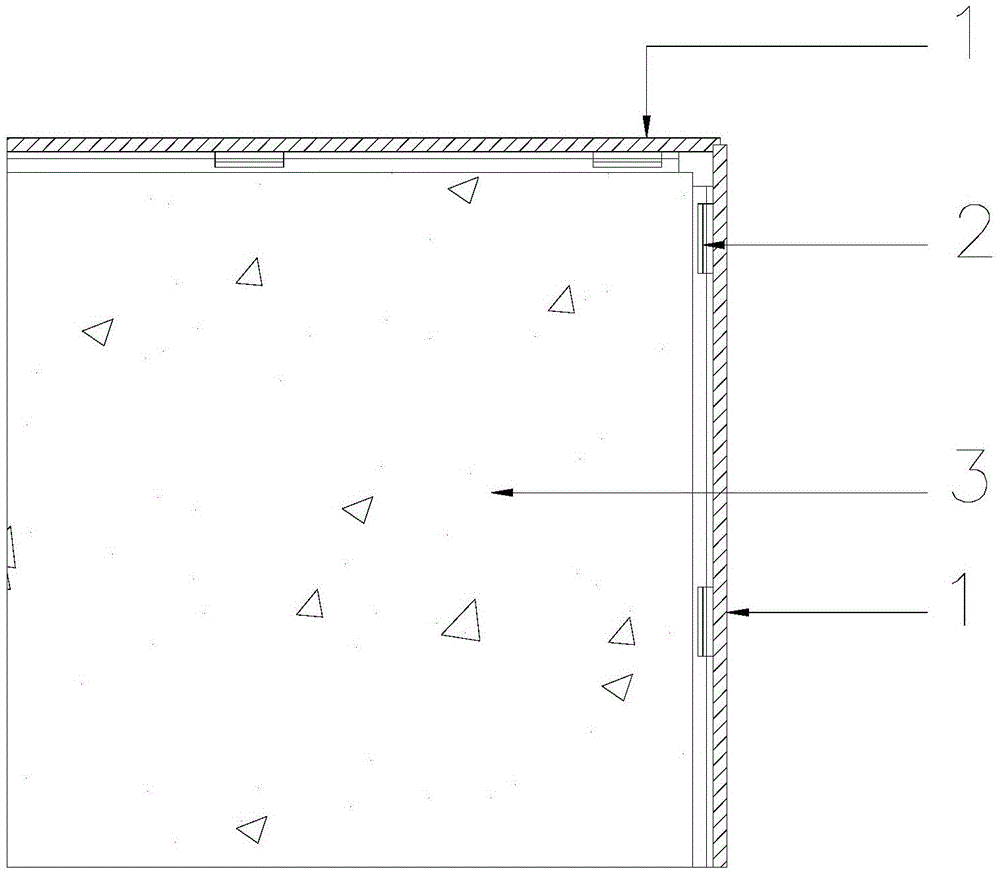

[0052]When the curved HPL board is used for building decoration, its installation method is the same as that of the traditional HPL board, such as figure 2 As shown, it can be directly installed on the wall infrastructure 3 through the keel buckle 2. The curved HPL board is mainly ...

Embodiment 2

[0054] In this embodiment, a method for manufacturing a curved HPL board for architectural decoration, which is used for the curved HPL board described in Embodiment 1, comprises the following steps:

[0055] (1) According to the bending radius of the designed curved HPL plate, the bending mold is designed through the three-dimensional modeling software and the mold engineering drawing is output, and then the mold is prefabricated, specifically:

[0056] (1-1) According to the surface morphology of the designed curved HPL plate, use three-dimensional modeling software (such as UG, PRO / ENGINEER and other software) to establish the upper mold and lower mold of the mold, and according to the designed bending radius of the HPL plate, in Set the amount of bending springback on the curved HPL board;

[0057] (1-2) On the upper mold and the lower mold, the contact surfaces with the curved HPL plate are respectively subjected to finishing treatment (the surface section of the upper mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com