Thermal insulation module radiant heating and cooling ground and ventilation air conditioner system

A technology for thermal insulation modules and air conditioning systems, which is applied in air conditioning systems, ventilation systems, space heating and ventilation, etc., and can solve problems such as poor thermal insulation, long construction period, and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

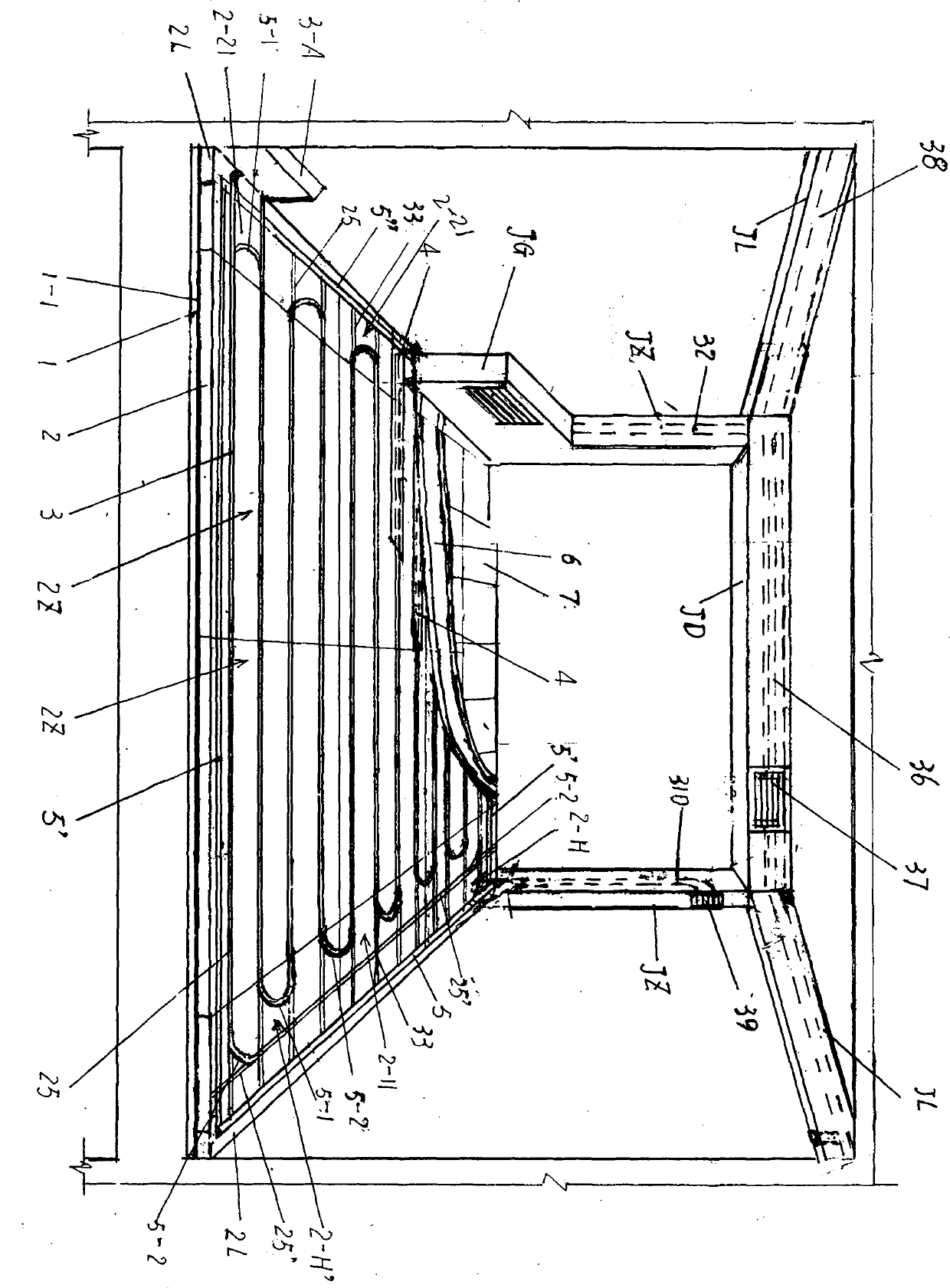

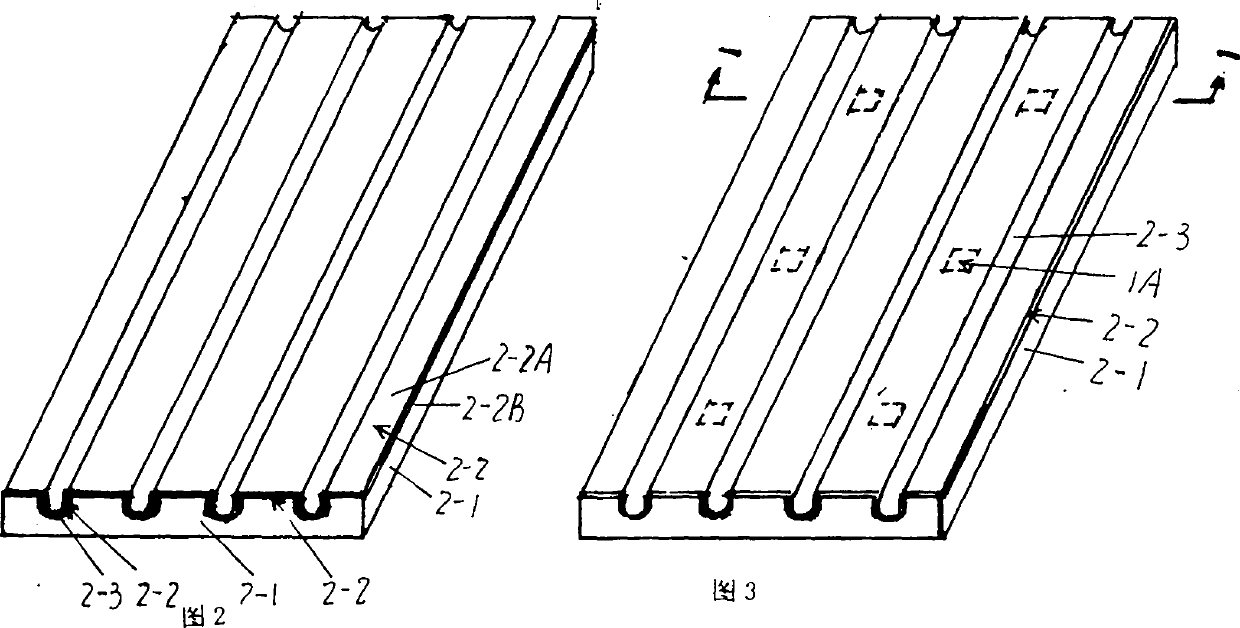

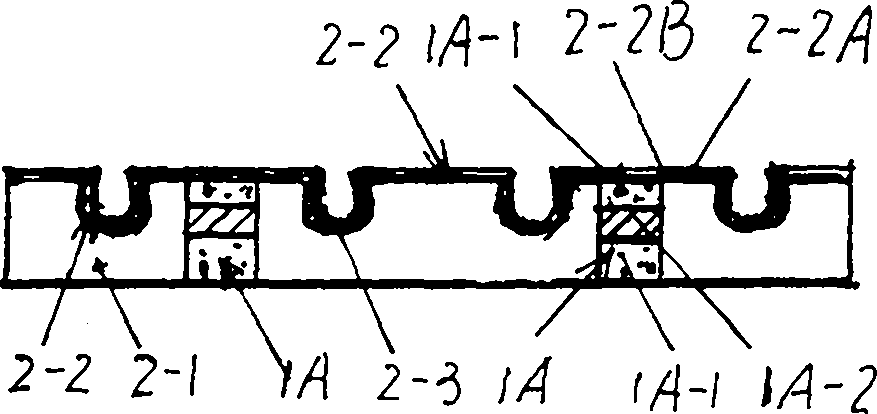

[0093] In order to express the present invention more clearly, the embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0094] Embodiment 1 of the present invention, such as figure 1 As shown, it is characterized in that it consists of leveling layer 1, polypropylene waterproof membrane layer 1-1, prefabricated combined thermal insulation module body 2, floor heating pipeline 3, air inlet main pipe 5, air inlet branch pipe 5', Exhaust dry pipe 5″, moisture-proof and heat-conducting layer 4′, bonding pad 6, ground veneer 7 or wooden floor, and ventilation and air-conditioning system; the prefabricated combined heat preservation module body 2, such as Figure 1 ~ Figure 4 As shown, it is composed of a thermal insulation module 2-1 and a waterproof and heat-conducting bonding layer 2-2; the upper end surface of the thermal insulation module 2-1, including the surface of the groove 2-3, is covered with a layer of 3-6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com