Dark field detection based optical-fiber macrobending coupling structure liquid-level probe

An optical fiber macro-bending and dark-field detection technology, which is applied in the field of liquid level probes, can solve problems such as poor stability, low precision, and poor robustness, and achieve the effects of increasing strength, ensuring stability, and low power consumption

Active Publication Date: 2014-12-10

ZHONGBEI UNIV

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the above problems, the present invention provides a liquid level probe with optical fiber macrobend coupling structure based on dark field detection, which solves the problems of poor stability, low precision and poor robustness in traditional liquid level measurement methods, and realizes low energy consumption and low cost. Special probes for safe and environmentally friendly liquid level detection systems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

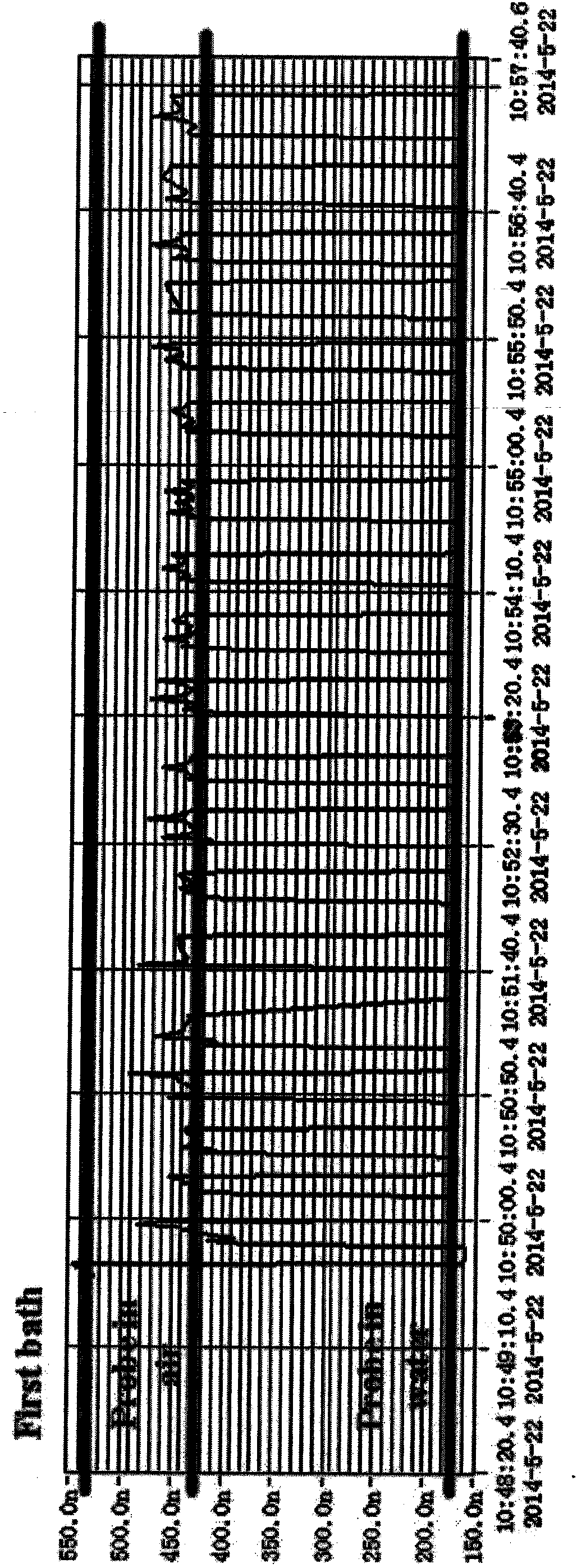

The invention discloses a dark field detection based optical-fiber macrobending coupling structure liquid-level probe. The liquid level sensing principle based on 'CMFTIR (cladding mode frustrated total internal reflection) effect' is proposed for the first time and applied successfully. By means of macrobending, mode field distribution in optical fibers is changed, ratio of cladding mode energy in the optical fibers is increased, and the CMFTIR effect is enhanced; meanwhile, due to macrobending radiation effect, macrobending coupling between the two optical fibers is realized; by means of macrobending coupling, a sensing signal is transferred to a dark field, modulation depth is increased during coupling, higher cladding mode energy ratio can be obtained in the passive optical fiber, and the CMFTIR effect is further enhanced; meanwhile, stability of the coupling structure and consistency of sensors are guaranteed, signal to noise ratio of increased by detection of effectiveness of dark field signals, the liquid-level probe is low in cost and power consumption and high in performance, and discrimination is higher than 4dB.

Description

technical field The invention relates to a liquid level probe, in particular to an optical fiber macrobend coupling structure liquid level probe based on dark field detection. Background technique In the field of petroleum, chemical and chemical production, the automatic detection of the liquid level of liquid chemicals is an important guarantee for safe operation; the monitoring of the fuel level during the operation of aircraft and ships also has a wide range of demands. At present, the traditional liquid level detection methods mainly include: mechanical float type, capacitive type, ultrasonic type, etc. Among them, mechanical float electronics have defects in automation and precision; capacitive sensors have certain safety hazards in flammable and explosive environments due to the introduction of electrical signals, and a large number of signal connection lines are very susceptible to electromagnetic interference; ultrasonic liquid Position sensors often have problems ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01F23/292

Inventor 刘文怡侯钰龙苏珊张会新刘俊熊继军甄成方张迦卫

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com