Liquid level sensor based on POF (plastic optical fiber) optical fiber macrobending

A liquid level sensor and optical fiber macrobend technology, applied in the field of sensors, can solve the problems of cost sensitivity, increased liquid viscosity, large volume, etc., and achieve the effects of simplified process difficulty, strong anti-pollution ability, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

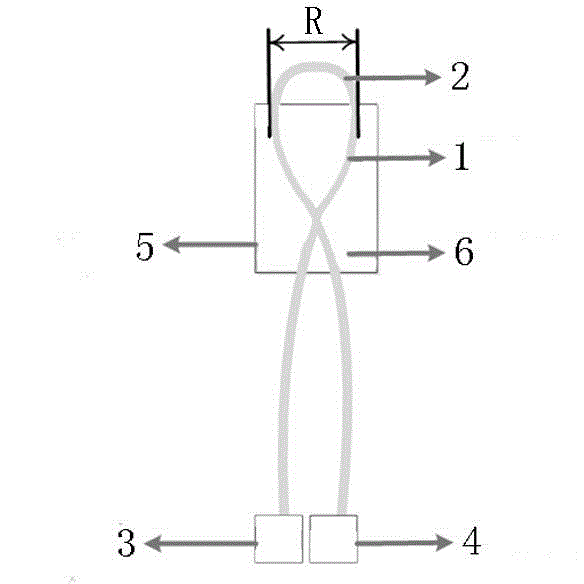

[0023] A POF bare fiber 1 (Mitsubishi, SK-40) is used to bend the top macrobend bending radius (R / 2) of 2.5mm single macrobend fiber ring structure, and the top macrobend part is used as the probe 2, and the POF bare fiber There are standard FC optical fiber connectors at both ends of the optical fiber, and the optical fiber connectors are respectively connected to the light source 3 and the power meter 4 in the test system. A standard FC optical fiber connector protective sleeve accessory is used as the fixed structure 5, and the single macrobend optical fiber ring structure is encapsulated in the fixed structure 5 with silica gel or epoxy resin 6, and the probe 2 is exposed from the top of the fixed structure 5. The outside of the POF bare optical fiber 1 other than the fixed structure 5 and the probe 2 is wrapped with a black heat-shrinkable sleeve. Its structure is as figure 1 shown.

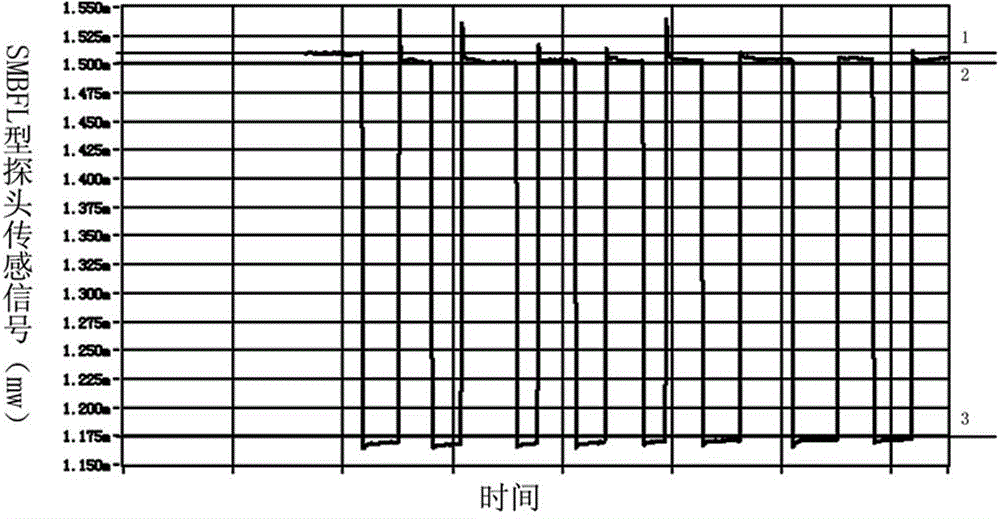

[0024] The fabricated SMBFL probe was subjected to a water immersion-outlet test. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com