MoS2 saturable absorber film prepared through magnetron sputtering method, and corresponding ultrashort pulse fiber laser

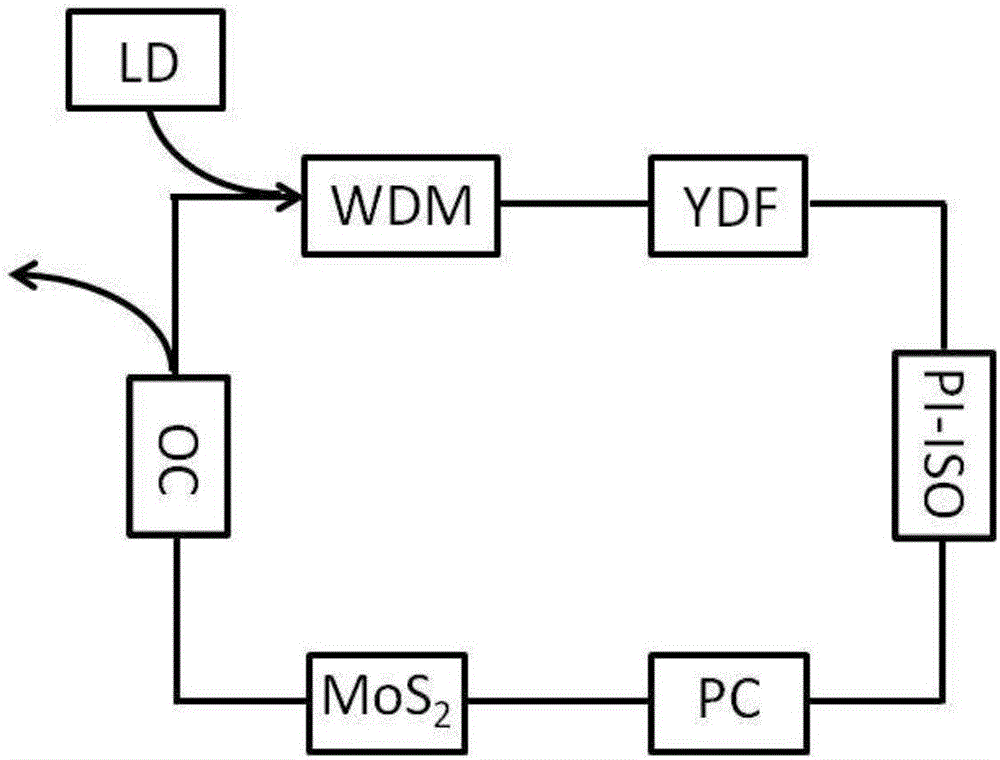

A saturable absorption, fiber laser technology, applied in the field of passive mode-locked fiber lasers, can solve the problems of weak light absorption of single atomic layer and small modulation depth, and achieve the effects of stable pulse performance, large modulation depth and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of MoS 2 A film saturable absorber, the preparation method comprising the following steps:

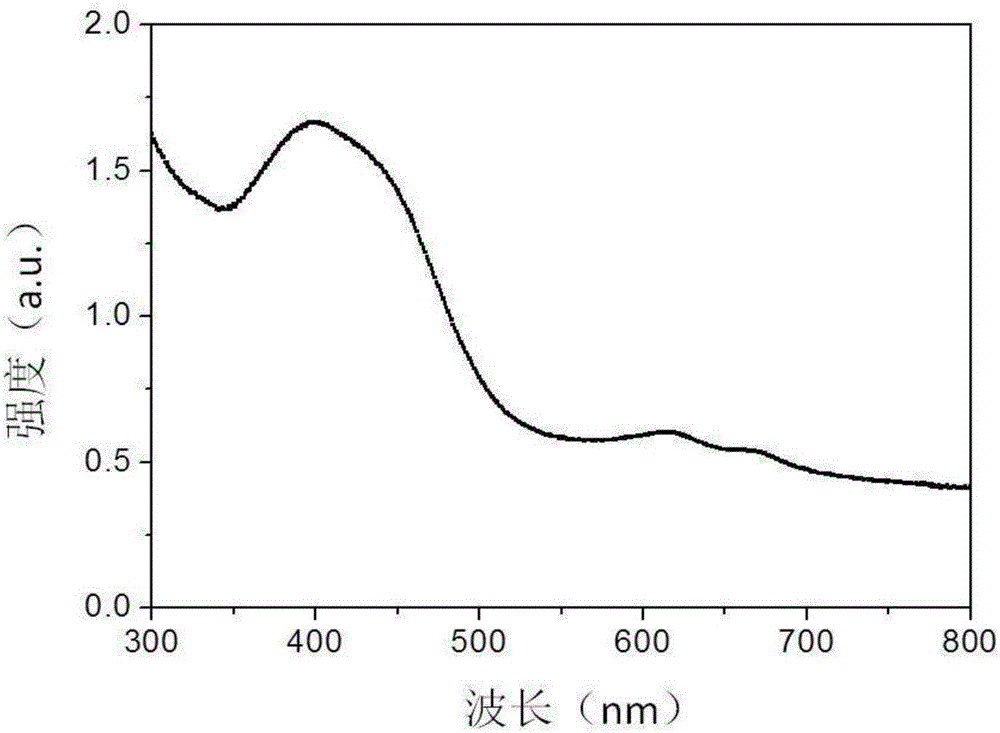

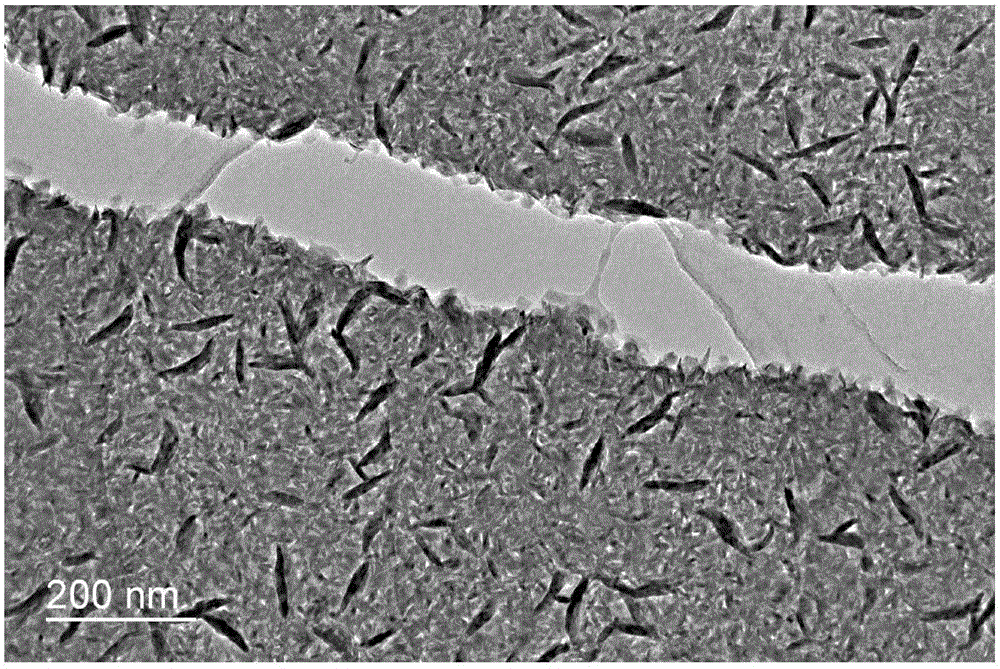

[0028] (1)MoS 2 Thin Film Preparation: MoS on Quartz Substrates by Magnetron Sputtering 2 thin films, in which MoS 2 The polycrystalline block is used as the target material, the RF power is 20W, the argon gas pressure is 1Pa, the quartz substrate is heated to 50°C, and the deposition is continued for 20min;

[0029] (2)MoS 2 Thin film heat treatment: MoS prepared by step (1) magnetron sputtering 2 The film is heat-treated in a tube furnace with argon as a protective gas at a flow rate of 20 sccm; high-purity sulfur powder is placed in the upstream low-temperature zone, and the temperature is set at 50°C, and the furnace center temperature is set at 550°C, and the temperature is naturally lowered after 10 hours to room temperature;

[0030] (3)MoS 2 Stripping of the film: using a PMMA / anisole solution with a mass fraction of 2%, spin-coating the MoS after heat trea...

Embodiment 2

[0033] A kind of MoS 2 A film saturable absorber, the preparation method comprising the following steps:

[0034] (1)MoS 2 Thin Film Preparation: MoS on Quartz Substrates by Magnetron Sputtering 2 thin films, in which MoS 2 The polycrystalline block is used as the target material, the RF power is 100W, the argon gas pressure is 100Pa, the quartz substrate is heated to 300°C, and the deposition is continued for 1min;

[0035] (2)MoS 2 Thin film heat treatment: MoS prepared by step (1) magnetron sputtering 2 The film is heat treated in a tube furnace with argon as a protective gas at a flow rate of 100 sccm; high-purity sulfur powder is placed in the upstream low-temperature zone, and the temperature is set at 180°C, and the furnace center temperature is set at 850°C, and the temperature is naturally lowered after 1 hour to room temperature;

[0036] (3)MoS 2 Stripping of the film: using a PMMA / anisole solution with a mass fraction of 10%, spin-coat the MoS after the heat t...

Embodiment 3

[0039] A kind of MoS 2 A film saturable absorber, the preparation method comprising the following steps:

[0040] (1)MoS 2 Thin Film Preparation: MoS on Quartz Substrates by Magnetron Sputtering 2 thin films, in which MoS 2 The polycrystalline block is used as the target material, the RF power is 60W, the argon gas pressure is 50Pa, the quartz substrate is heated to 200°C, and the deposition is continued for 5min;

[0041] (2)MoS 2 Thin film heat treatment: MoS prepared by step (1) magnetron sputtering 2 The film is heat treated in a tube furnace with argon as a protective gas at a flow rate of 100 sccm; high-purity sulfur powder is placed in the upstream low-temperature zone, and the temperature is set at 200°C, and the furnace center temperature is set at 800°C, and the temperature is naturally lowered after 2 hours to room temperature;

[0042] (3)MoS 2 Stripping of the film: using a PMMA / anisole solution with a mass fraction of 5%, spin-coating the MoS after the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com