Device and method for writing gratings on lithium niobate waveguides by aid of femtosecond laser device

A technology of femtosecond lasers and waveguide gratings, applied in the field of femtosecond lasers and waveguide gratings, can solve the problems of low precision, fixed grating period, inflexible adjustment, etc., and achieve high precision, flexible and variable structure, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

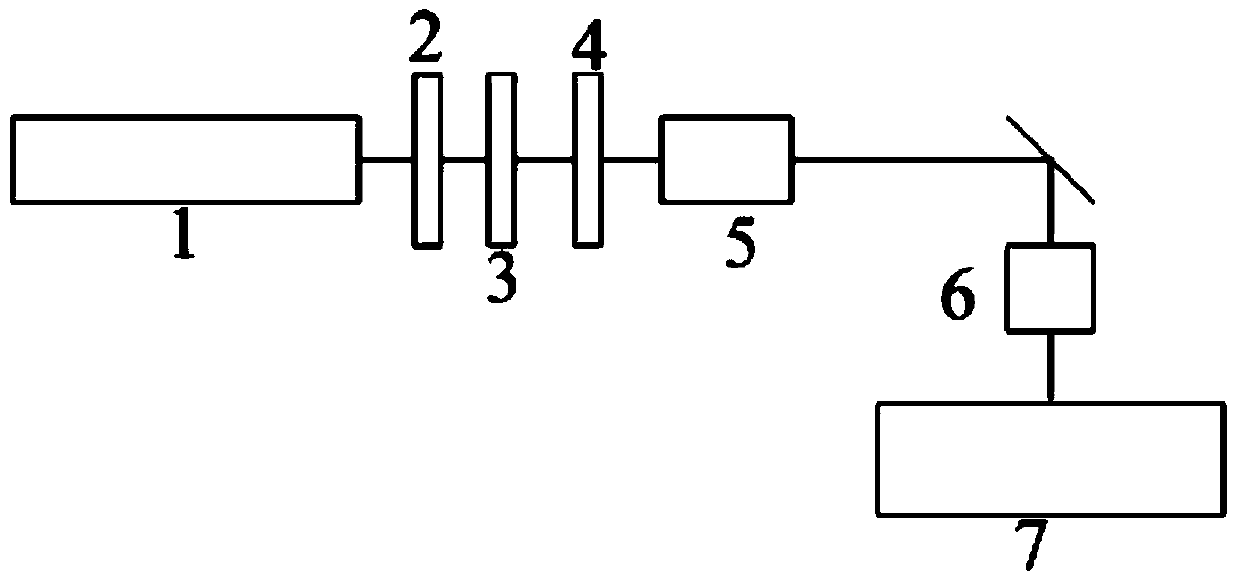

[0034] A device for writing a grating on a lithium niobate waveguide using a femtosecond laser, the structure diagram is as follows figure 1 As shown, the device includes a femtosecond laser 1 , a collimation system 2 , and an attenuation system 3 , a shutter 4 , a filtering system 5 , a focusing system 6 and a displacement platform system 7 arranged in sequence along the optical path.

[0035] The collimation system includes two mirrors and two adjustable diaphragms, and the connection sequence is mirror-reflector-adjustable diaphragm-adjustable diaphragm;

[0036] The attenuation system includes a Glan Taylor prism, a half-wavelength plate, and a set of neutral density filters, and the connection sequence is a half-wavelength plate-Glan Taylor prism-neutral density filter;

[0037] The filter system includes an objective lens, a pinhole and a lens, and the connection sequence is objective lens-pinhole-lens;

[0038] The displacement platform system is composed of a precisio...

Embodiment 2

[0044] A device for writing a grating on a lithium niobate waveguide using a femtosecond laser, with a structure such as figure 1 Shown, with embodiment 1.

[0045] Method steps for writing a grating on a lithium niobate waveguide:

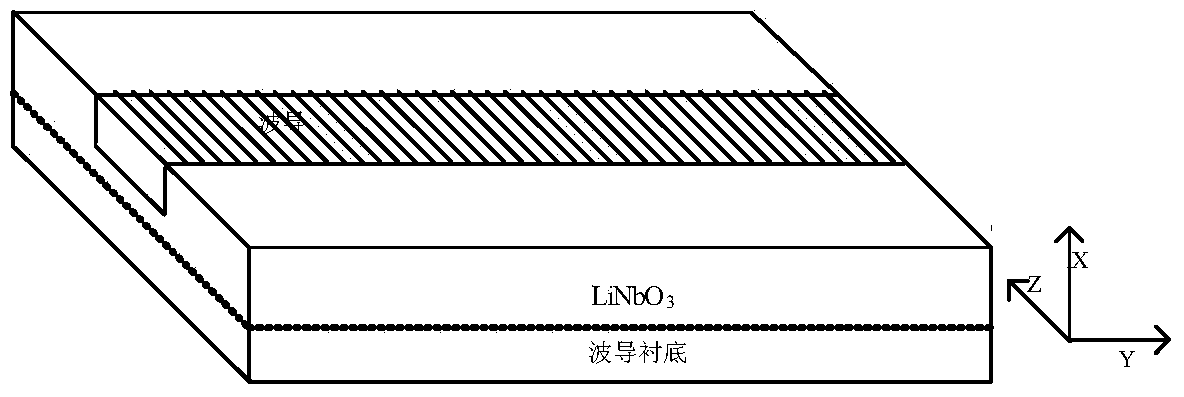

[0046] The femtosecond laser is used as the light source to output a certain power of light pulses. After the attenuation system is attenuated, the number of pulses passed by the shutter is controlled, and then the beam filtered by the filter system is focused by the focusing system and irradiated on the displacement platform equipped with lithium niobate waveguide. above. The lithium niobate waveguide sample used is X-cut, the size is 13.5mm*9mm*0.5mm, the width of the waveguide is 8um; the wavelength of the femtosecond laser is 780nm, the repetition frequency is 80MHZ, the output power is 1.91W, and the pulse width is 80fs; filtering The system uses a 20x objective lens, a 3um pinhole, and f50, φ30 double cemented achromatic lenses. We use a ...

Embodiment 3

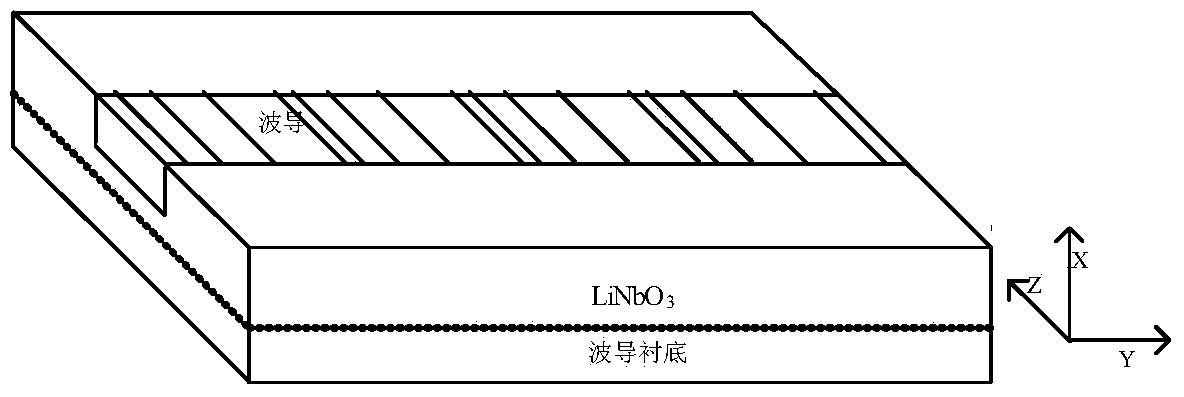

[0049] A device for writing a grating on a lithium niobate waveguide using a femtosecond laser, with a structure such as image 3 Shown, with embodiment 1.

[0050] Method steps for writing a grating on a lithium niobate waveguide:

[0051] The femtosecond laser is used as the light source to output a certain power of light pulses. After the attenuation of the attenuation system, the number of pulses passed by the shutter is controlled, and then the beam filtered by the filter system is focused by the focusing system and irradiated on the displacement platform equipped with lithium niobate waveguide. above. The lithium niobate waveguide sample used is X-cut, the size is 13.5mm*9mm*0.5mm, the width of the waveguide is 8um; the wavelength of the femtosecond laser is 780nm, the repetition frequency is 80MHZ, the output power is 1.91W, and the pulse width is 80fs; filtering The system uses a 20x objective lens, a 3um pinhole, and f50, φ30 double cemented achromatic lenses. We u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com