Assembly of a porous metal diffusion substrate and a polymeric separator membrane

A technology of porous metals and polymers, applied in diaphragms, electrolytic components, fuel cell components, etc., can solve problems such as reduced efficiency of electrolytic cells or fuel cells, restrictions on the maximum operating temperature of electrolytic cells, and increased size of electrolytic cell stacks. Achieve the effect of increasing performance and efficiency, increasing stability, and high flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

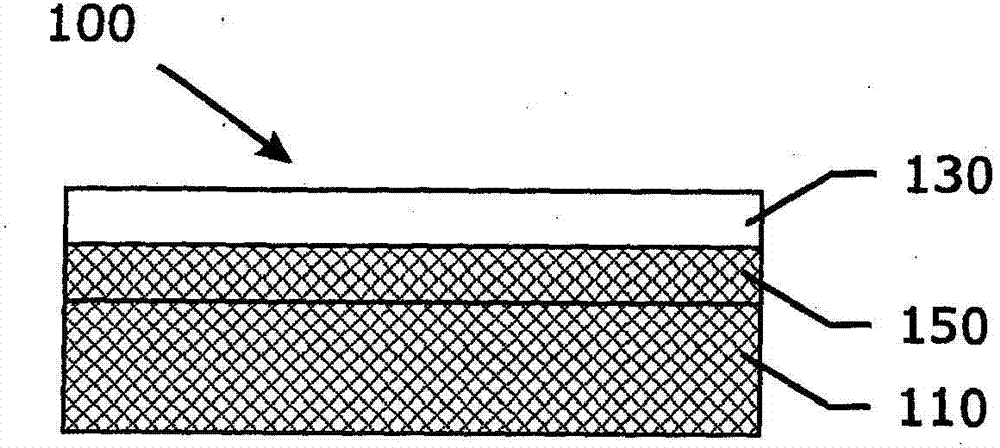

[0069] figure 1 An example of an assembly 100 of a porous metallic gas diffusion substrate 110 and a polymeric separator membrane 130 as in the first aspect of the invention is shown. The polymeric separator membrane 130 is infiltrated into the top 150 of the porous metallic gas diffusion substrate 110 .

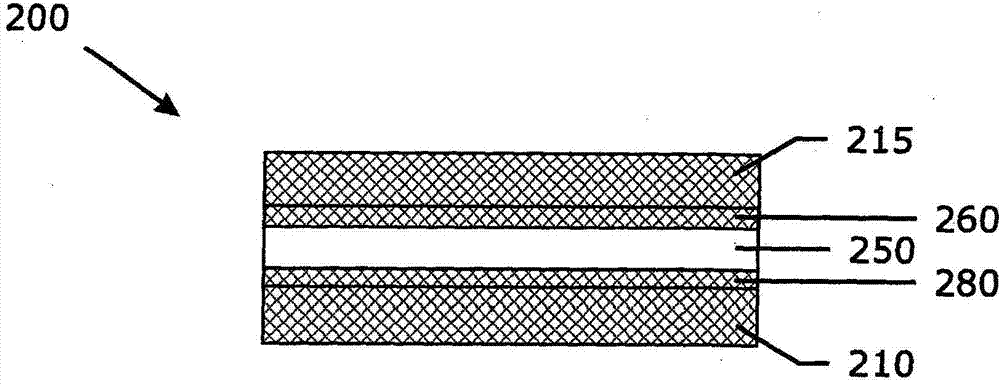

[0070] figure 2 An example of an assembly 200 is shown of two porous metallic gas diffusion substrates 210, 215 with a polymeric separator membrane 250 in between, wherein the polymeric separator membrane 250 penetrates the top portion 260 of the two porous metallic gas diffusion substrates 210, 215 , 280.

[0071] An example of a slurry which can be used according to the invention to coat the membrane layer on the porous metallic gas diffusion layer comprises 49.07% by weight of zirconia (for example type E101 from MEL-Chemical), 8.66% by weight of polysulfone, % of glycerol and 41.17% by weight of N-ethylpyrrolidone (NEP).

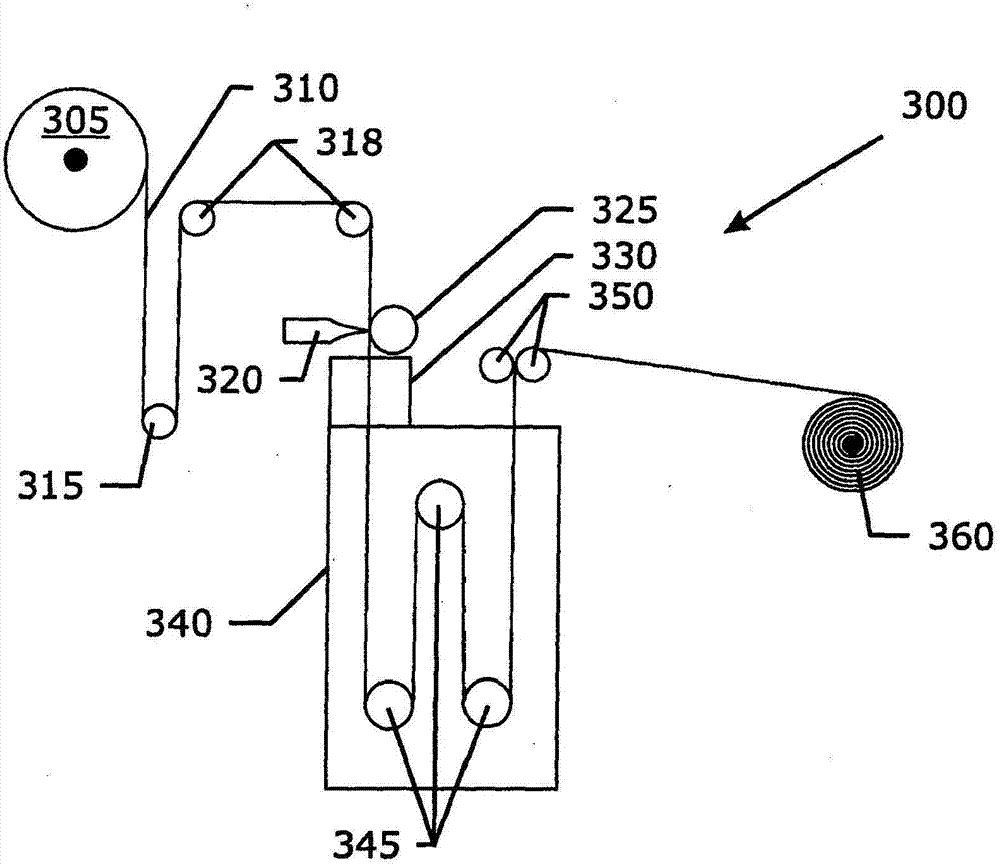

[0072] image 3 An example of a coating an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com