A method for controlling phosgene leakage

A phosgene and funnel technology, applied in the direction of phosgene, can solve the problems of simple layout, no alarm system and chain false alarm, collection and treatment of waste gas and waste liquid, etc., to prevent phosgene diffusion and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

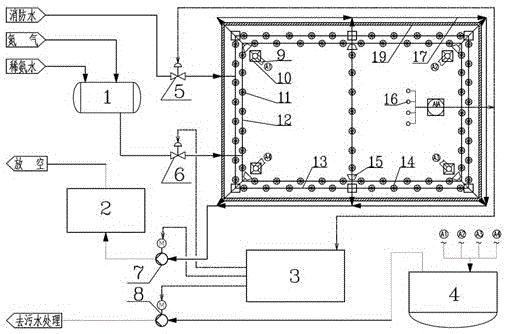

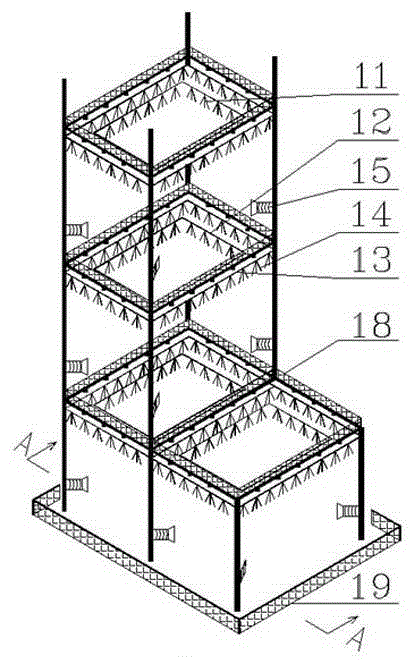

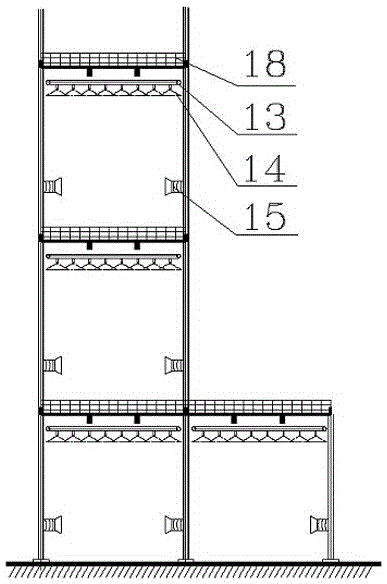

[0036] (1) Installation of equipment for controlling phosgene leakage

[0037] Each layer of frame structure in the phosgene synthesis and photochemical reaction boundary area is equipped with an outer layer of pressure-holding water pipeline 13 and an inner layer of ammonia water pipeline 12. The two pipelines have the same height and are arranged close to the roof of the frame structure. Each layer of frame structure A cofferdam is provided, wherein the upper cofferdam 18 on the second floor and above is arranged along the outer edge of the frame structure, and the ground cofferdam 19 on the ground is arranged at a certain distance from the outer edge of the frame; a Negative pressure extraction elephant trunk pipe 15, negative pressure extraction elephant trunk pipe 15 is connected with waste gas main pipe 17, waste liquid funnels 10 are arranged at the four corners of each frame structure, and waste liquid funnels 10 on the ground are arranged equidistantly around the frame...

Embodiment 2

[0050] The distance between the pressure-holding water pipeline 13 and the ammonia water pipeline 12 is 0.6m. The height of the upper cofferdam 18 is 20cm, and the ground cofferdam 19 is arranged 2m away from the outer edge of the frame, and its height is 0.4m. Negative pressure extraction elephant trunk pipe 15 is 1m apart from the floor floor height. The horizontal distance between the four corner waste liquid funnels 10 of each frame structure and the cofferdam of this layer is 0.3m, and the distance between every two waste liquid funnels 10 on the ground is 15m.

[0051] Phosgene detectors are equipped with phosgene detectors 16 at 50 cm downwind of the equipment flanges of the phosgene synthesis tower, the phosgenation reactor, the liquid phosgene pump, the phosgene cooler and the condenser, and the phosgene inlet and outlet flanges; For pipelines with a mass content of phosgene of more than 10-100%, install a detector at the lower 50cm of the pipeline every 30m; And th...

Embodiment 3

[0058] The distance between the pressure-holding water pipeline 13 and the ammonia water pipeline 12 is 0.4m. The height of the upper cofferdam 18 is 15cm, and the ground cofferdam 19 is arranged 1m away from the outer edge of the frame, and its height is 0.3m. Negative pressure extraction elephant trunk pipe 15 is 0.7m apart from the floor floor height. The horizontal distance between the four corner waste liquid funnels 10 of each frame structure and the cofferdam of this layer is 0.2m, and the distance between every two waste liquid funnels 10 on the ground is 10m.

[0059]Phosgene detectors are equipped with phosgene detectors 16 at 40 cm downwind of the equipment flanges of the phosgene synthesis tower, the phosgenation reactor, the liquid phosgene pump, the phosgene cooler and the condenser, and the phosgene inlet and outlet flanges; For pipelines with a mass content of phosgene of more than 10-100%, a detector is installed at the lower 40cm of the pipeline every 20m; f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com