Atomization production system of aluminum alloy and aluminum alloy powder

A production system and technology of aluminum alloy, applied in the field of aluminum alloy and aluminum alloy powder production, can solve problems such as insufficient cooling rate, product performance to be improved, and inability to guarantee cooling efficiency, etc., to improve atomization energy conversion rate, resistance Small, the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

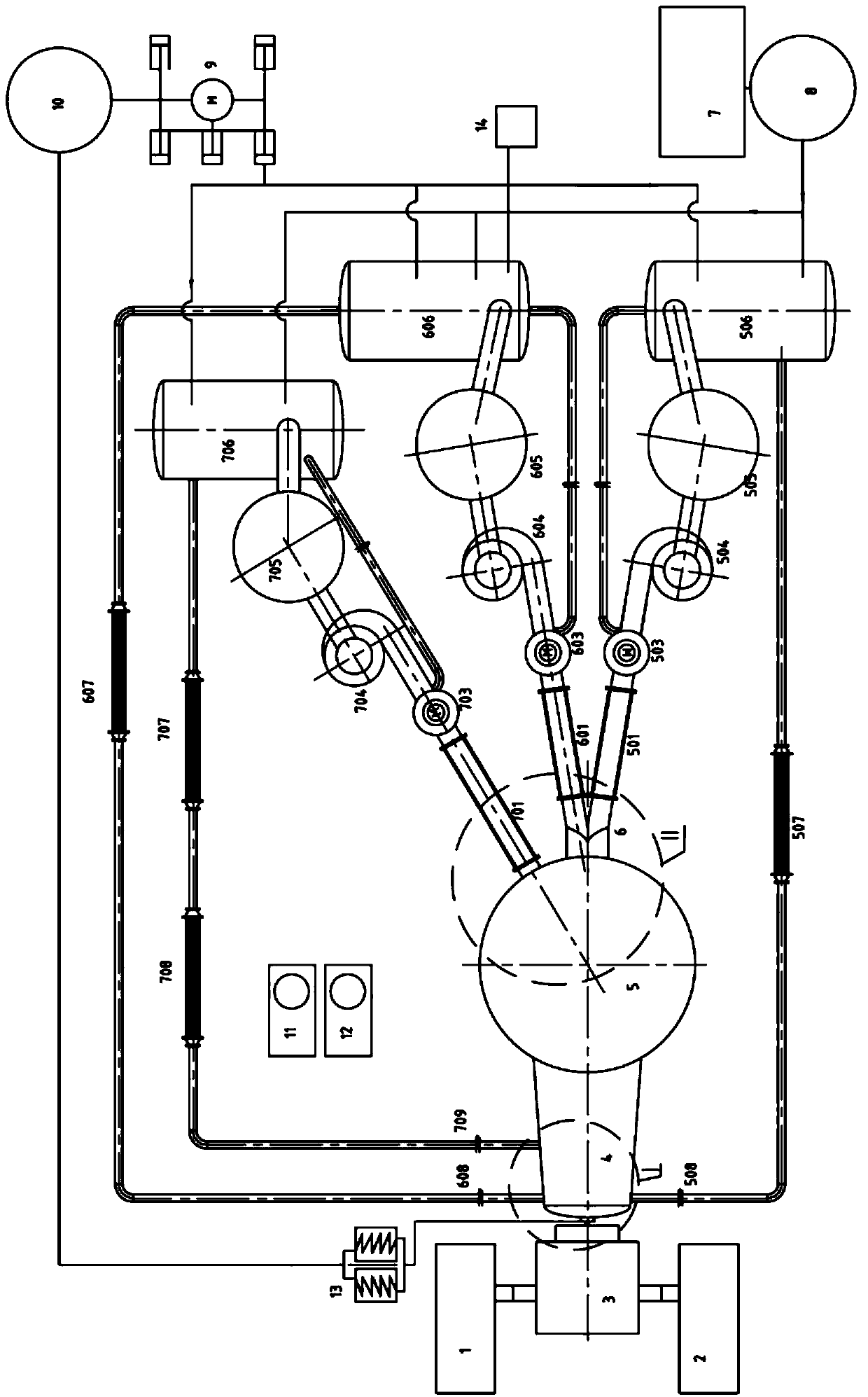

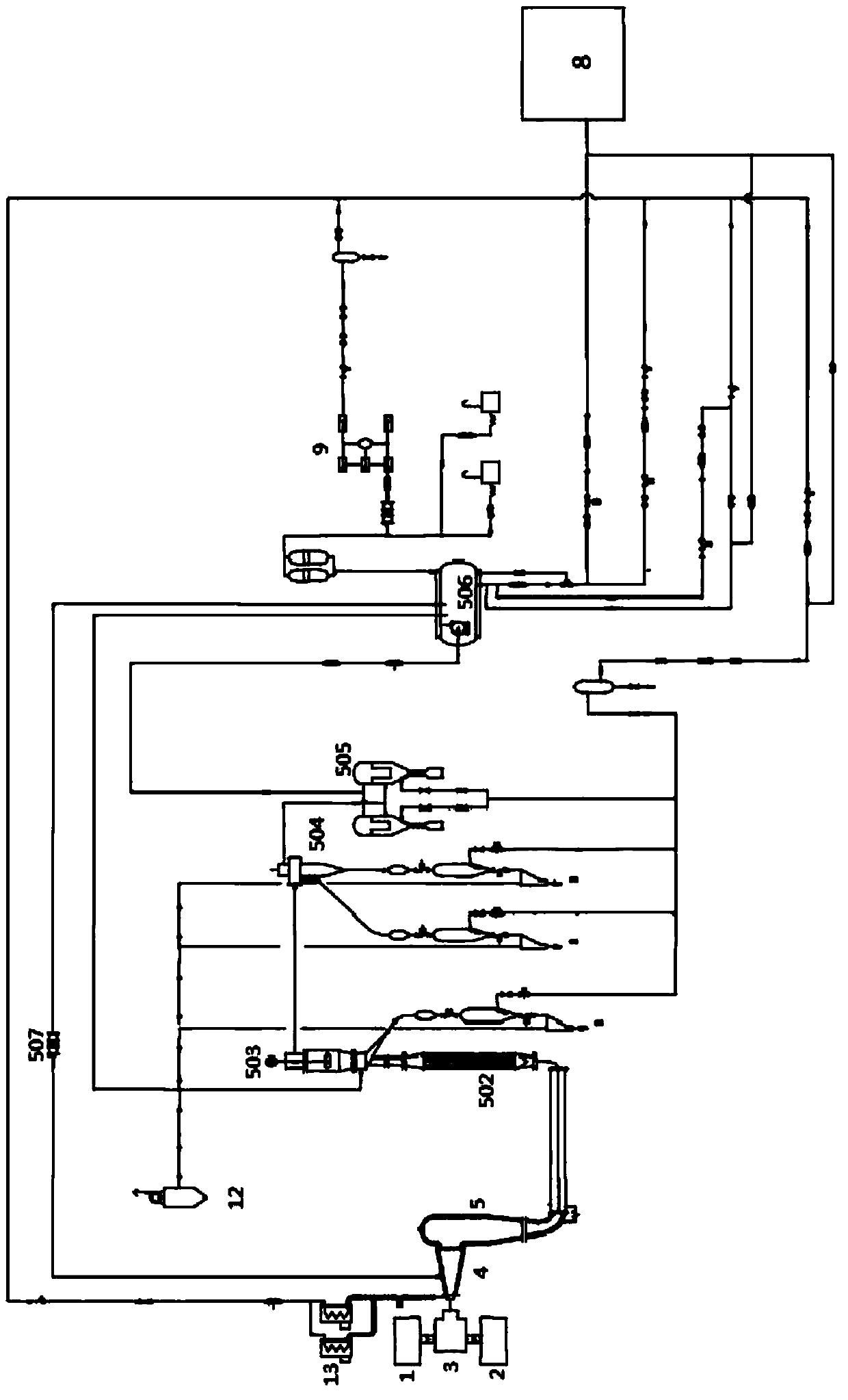

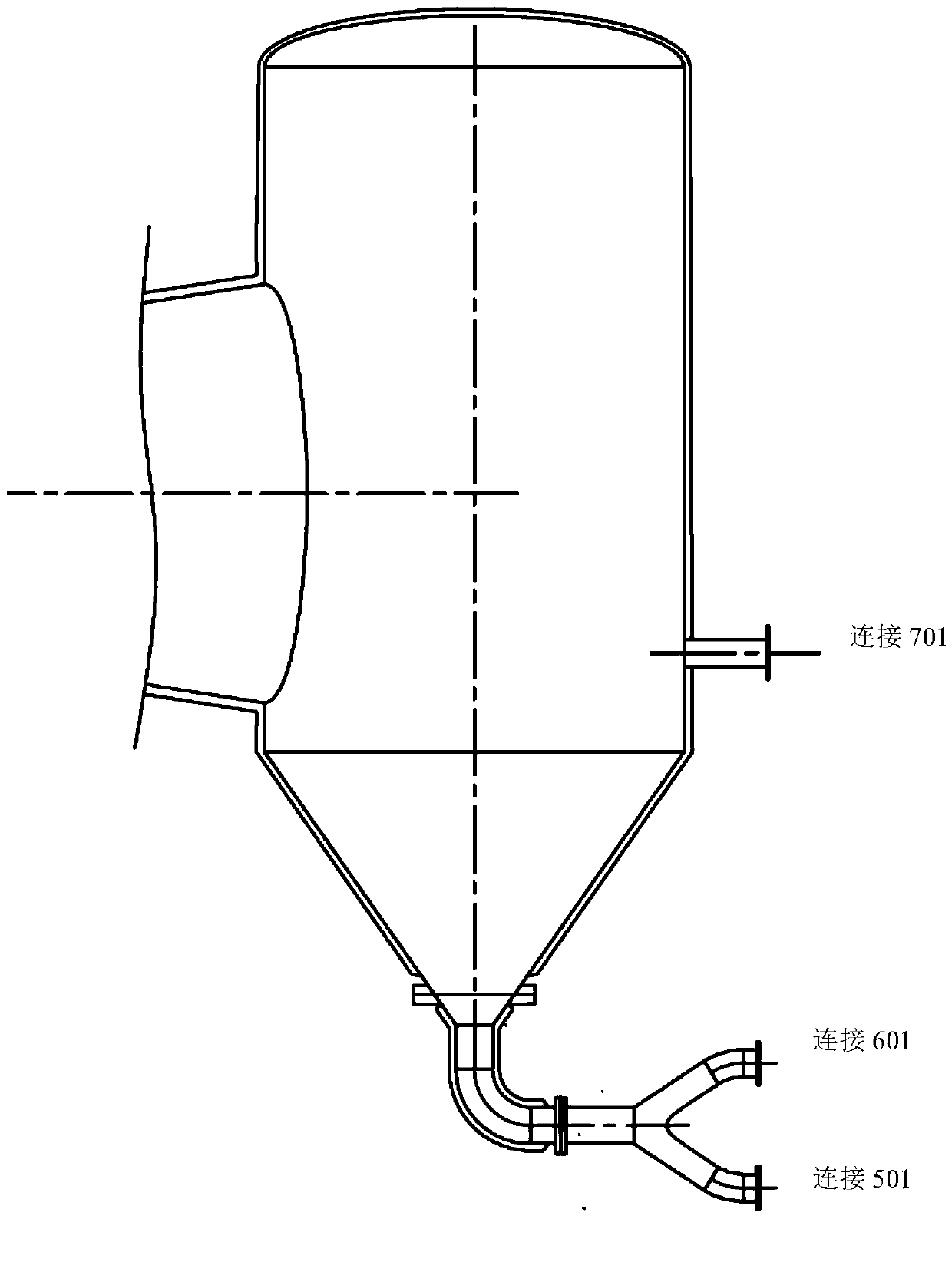

[0036] Such as figure 1 , figure 2 As shown, the atomization production system of the present invention includes melting furnaces 1 and 2, holding furnace 3, spraying device 4, atomization settling chamber 5, three sets of classification systems and ventilators connected in sequence, and includes cooling systems 11 and 12, Nitrogen compression system 9, nitrogen production system 7, the atomization settling chamber 5 communicates with three sets of classification systems,

[0037] The first classification system includes the first cooler 501, the first centrifugal classifier 503, the first cyclone classifier 504, the first bag filter 505 and the first air pressure balance tank 506 connected in sequence,

[0038] The second classification system includes a second cooler 601, a second centrifugal classifier 603, a second cyclone classifier 604, a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com