Co-extrusion molding device for wood plastic-solid wood composite material

A composite material and forming device technology, applied in the direction of coating, etc., can solve problems such as extrusion of solid wood materials that are not suitable for rigidity, and achieve the effects of improving material processing performance and interface performance, improving interface bonding strength, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

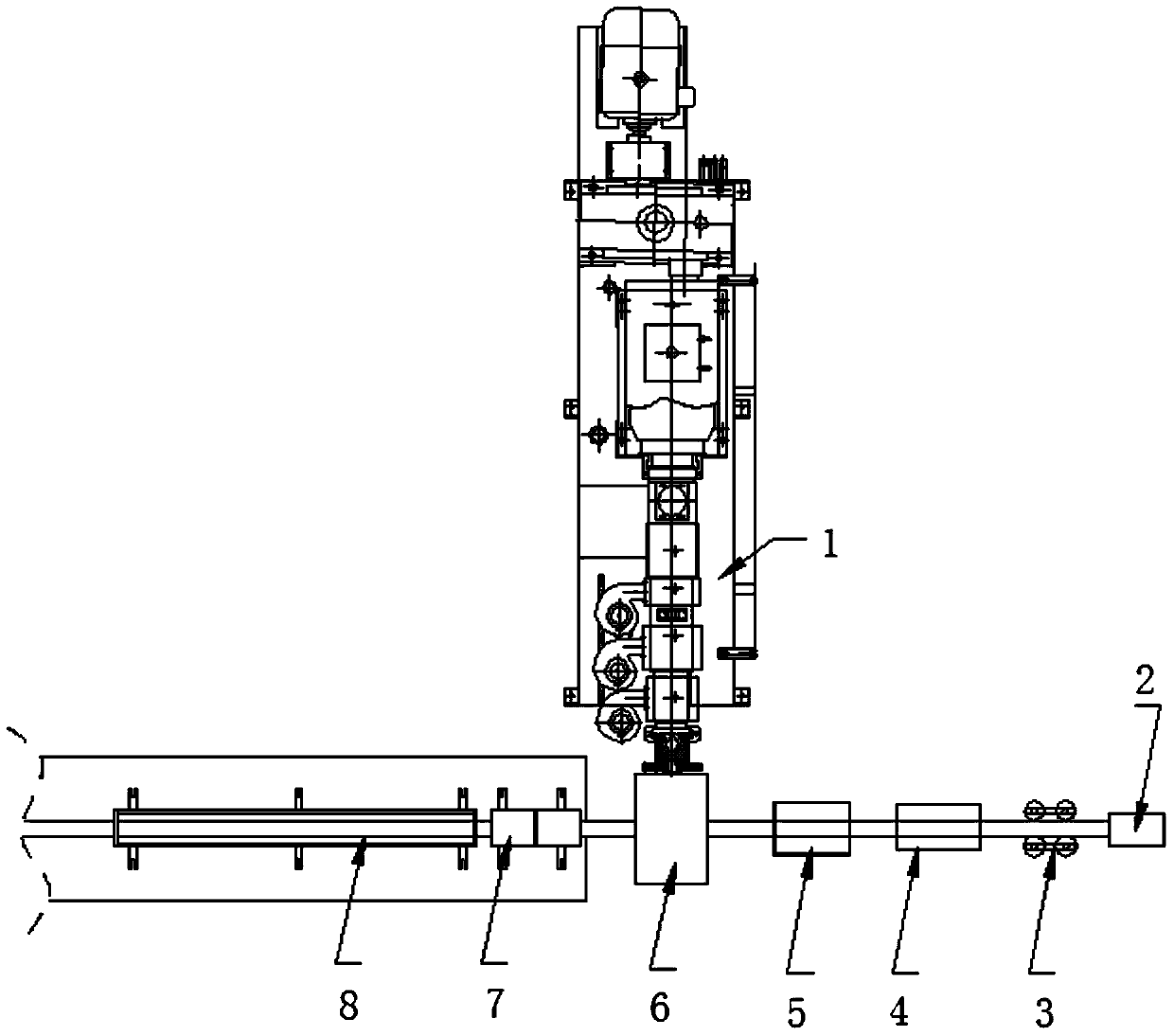

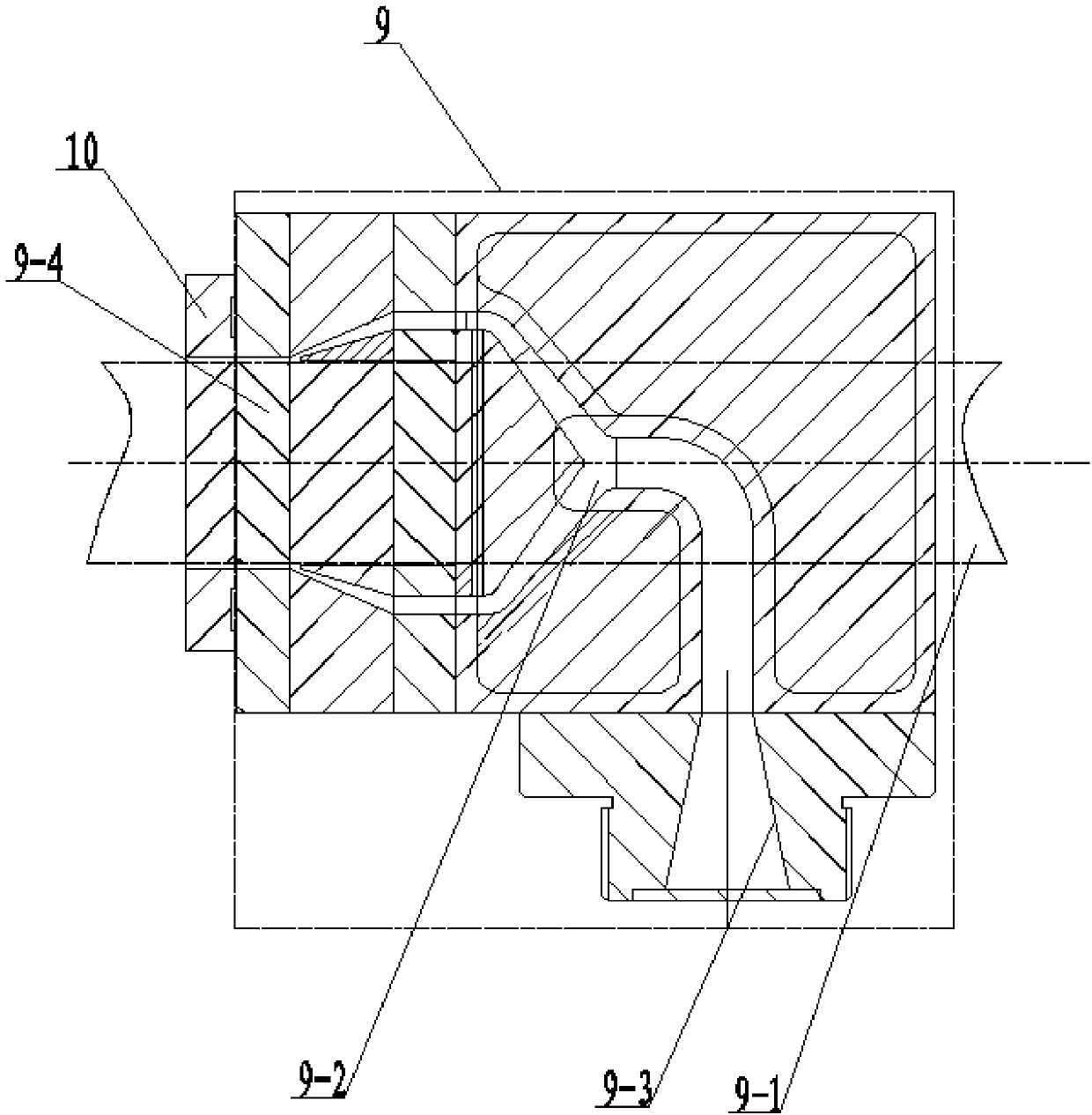

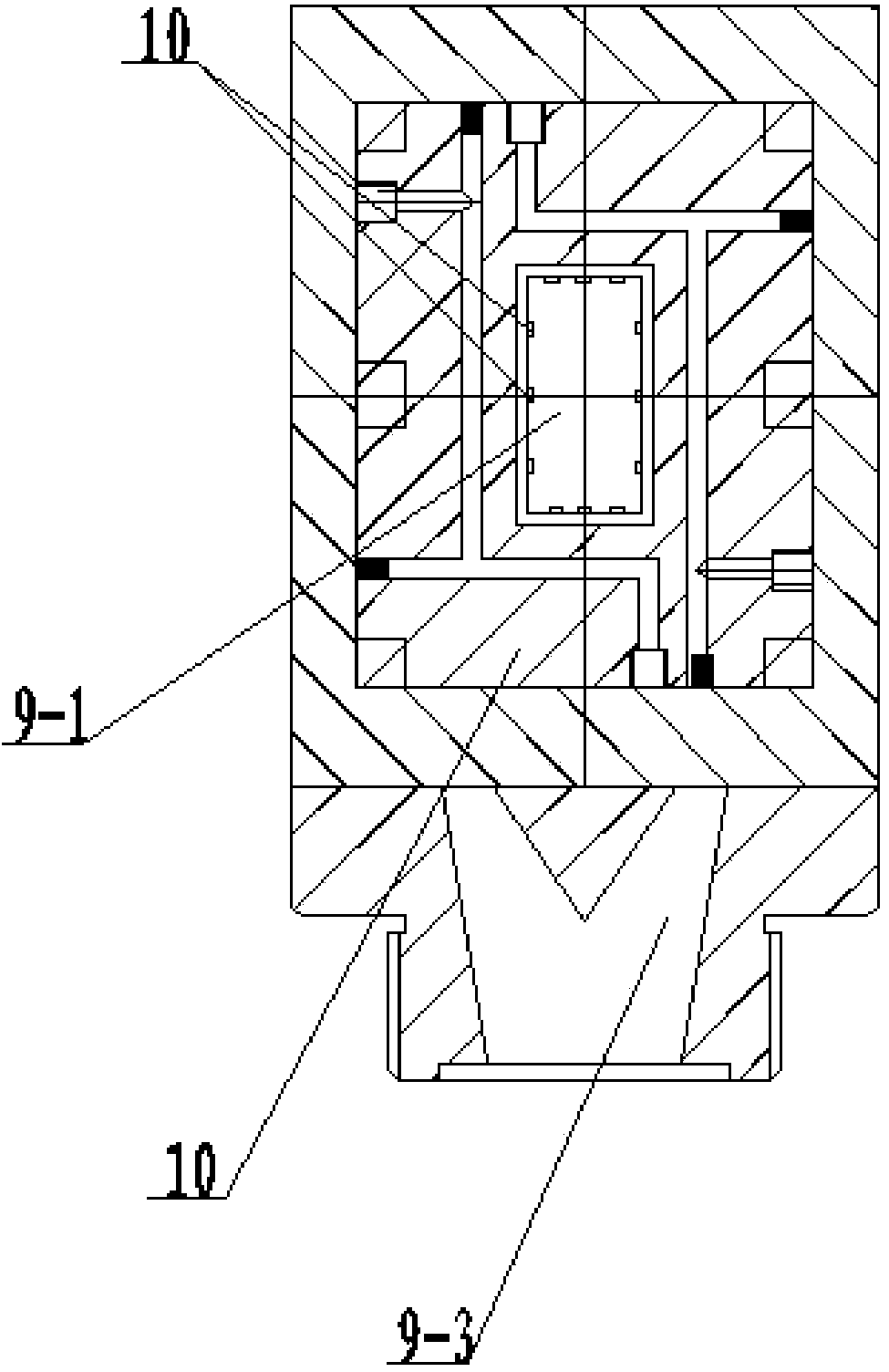

[0013] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, a kind of wood-plastic solid wood composite material co-extrusion molding device of this embodiment comprises wood-plastic extruder 1, co-extrusion die 6, solid wood conveying device and cooling setting device, co-extrusion die 6 is detachable form Installed on the head of the wood-plastic extruder 1, the solid wood conveying device and the cooling and shaping device are respectively installed at the left and right ends of the co-extrusion die 6, and the solid wood conveying device includes a solid wood quick connecting device 2, a solid wood conveyor 3, a remote Infrared dryer 4 and gluing device 5, solid wood quick connection device 2, solid wood conveyor 3, far-infrared dryer 4 and gluing device 5 are arranged sequentially from right to left, and gluing device 5 is arranged at the right end of co-extrusion die 6 The cooling and sizing device includes a sizing die 7...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 , figure 2 and image 3 The present embodiment will be described. The taper of the branch flow channel of the present embodiment is 10° to 20°. In this way, the shunt flow channel becomes tapered and becomes smaller to facilitate extrusion and pressure building. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 , figure 2 and image 3 The present embodiment will be described. The taper of the branch channel of the present embodiment is 12.5°. With such setting, the diversion channel becomes tapered and becomes smaller, and the effect of extrusion pressure building is the best. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com