Device for processing high-concentration ammonia nitrogen in rare-earth wastewater by using surfactant

A surfactant, high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, large pollution, low ammonia nitrogen removal rate, etc. Achieve the effect of reducing pollution, uniform fiber distribution and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

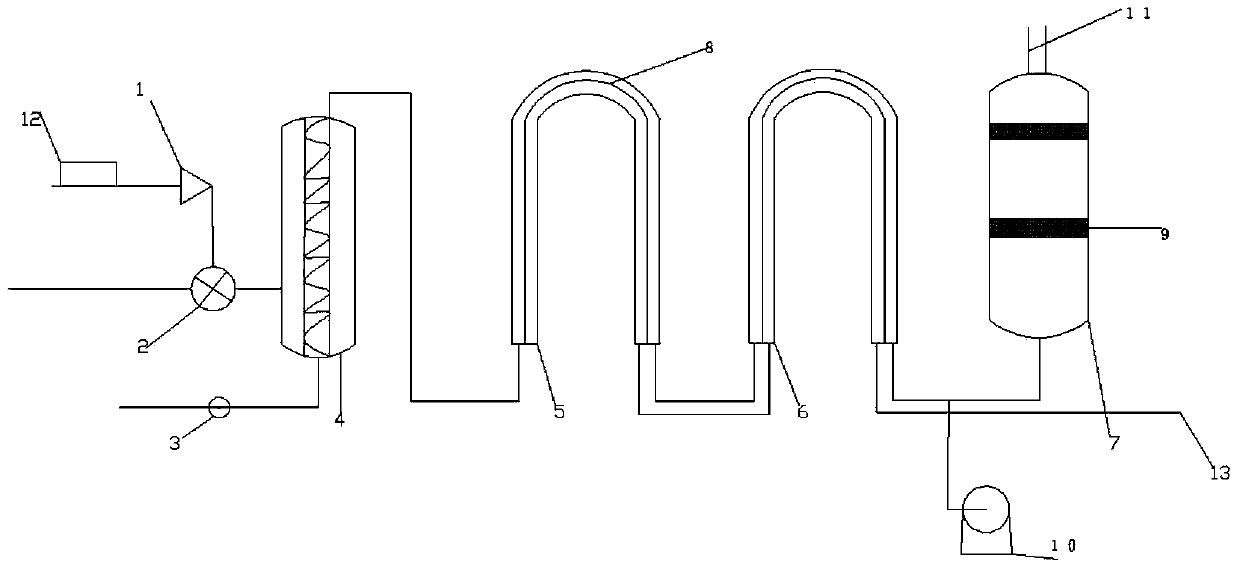

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] like figure 1 As shown, the present invention provides a surfactant treatment device for high-concentration ammonia nitrogen in rare earth wastewater, consisting of an air compressor (1), a high-pressure pump (2), a high-pressure steam pump (3), a heat exchanger (4), and a first-stage denitrification device (5), secondary denitrification device (6), catalytic reduction tank (7), quartz glass fiber membrane (8), heavy metal catalyst (9), induced draft fan (10), exhaust port (11), liquid medicine tank (12) and waste water outlet (13) constitute; Air compressor (1), high pressure pump (2), high pressure steam pump (3) are connected with heat exchanger (4), and air compressor (1) is positioned at the high pressure pump Above, the high-pressure steam pump (3) is located below the heat exchanger (4) to provide steam, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com