A kind of transparent silicone gel for stable and oil-proof electronic components

A technology of electronic components and silicone gel, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problem that the volatile content of raw materials cannot be effectively reduced, and achieve the effects of avoiding oil leakage, good adhesion, and reducing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

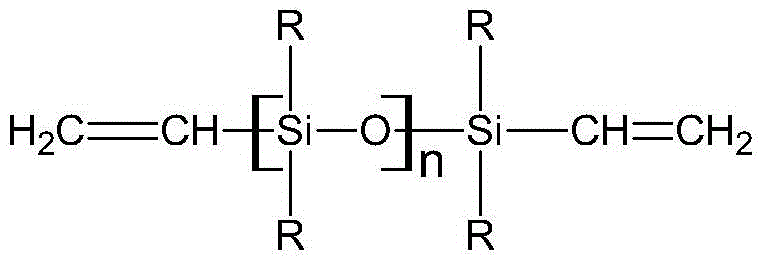

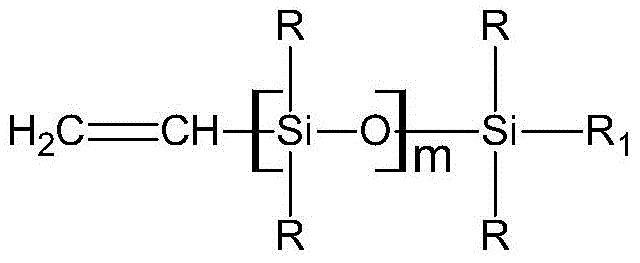

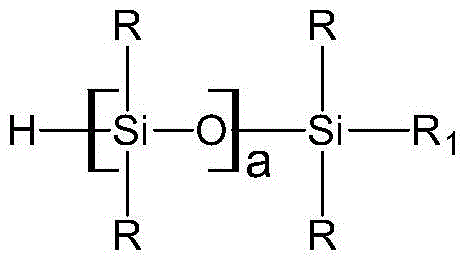

Method used

Image

Examples

Embodiment 1

[0029] Preparation of component A: Accurately weigh 50 g of diethylene-terminated polydimethyl silicone oil with a vinyl content of 0.6% and a viscosity of 200 cs, 30 g of a diethylene-terminated polydimethyl silicone oil with a vinyl content of 0.42% and a viscosity of 500 cs, vinyl content 0.16% Polydimethylsiloxane 20g with a viscosity of 500cs, one end of vinyl and one end of methyl end capping, platinum-vinyl polydimethylsiloxane, wherein the mass of platinum is 0.0012g, fully mixed evenly by vacuum defoaming machine Then prepare component A.

[0030] Preparation of component B: Accurately weigh 83 g of diethylene-terminated polydimethylsiloxane oil with a vinyl content of 0.26% and a viscosity of 1000cs, 5g of a hydrogen-end-end methyl-terminated polydimethylsiloxane oil with a hydrogen content of 0.042% and a viscosity of 25cs, and hydrogen 10g of hydrogen-terminated polydimethylsiloxane with a viscosity of 0.1% and a viscosity of 30cs, 2g of polyhydrogen-containing sil...

Embodiment 2

[0033] Preparation of component A: Accurately weigh 85g of diethylene-terminated polydimethylsiloxane with a vinyl content of 0.21% and a viscosity of 2000cs, 1000cs of a vinyl content of 0.09% end-capped polydimethylsiloxane with a vinyl group at one end and a methyl group at the other end 15g, platinum-vinyl polydimethylsiloxane, in which the mass of platinum is 0.001g, and the component A is prepared after being thoroughly mixed uniformly with a vacuum defoaming machine.

[0034] Preparation of component B: Accurately weigh 36g of diethylene-terminated polydimethylsiloxane oil with vinyl content 0.13% viscosity 5000cs, vinyl content 0.42% viscosity 500cs diethylene-terminated polydimethylsilicone oil 50g, hydrogen content 0.018% viscosity 10g of 50cs polydimethylsiloxane with hydrogen at one end and methyl end at one end, 2g of polydimethylsiloxane with hydrogen at both ends of 20cs with 0.08% hydrogen content, 2g of hydrogen-containing silicone oil with 0.5% hydrogen conten...

Embodiment 3

[0037]Preparation of component A: Accurately weigh 71.25 g of diethylene-terminated polydimethyl silicone oil with a vinyl content of 0.26% and a viscosity of 1000 cs, 23.75 g of a diethylene-terminated polydimethyl silicone oil with a vinyl content of 0.42% and a viscosity of 500 cs, ethylene 5g of 2000cs polydimethylsiloxane with a vinyl group at one end and a methyl group at the other end with a base content of 0.06%, platinum-vinyl polydimethylsiloxane, wherein the mass of platinum is 0.002g, fully mixed with a vacuum defoamer Prepare A component after homogenization.

[0038] Preparation of component B: Accurately weigh 60g of diethylene-terminated polydimethylsiloxane oil with a vinyl content of 0.6% and a viscosity of 200cs and a hydrogen content of 0.19% with a viscosity of 5cs and 2g of a methyl-terminated polydimethylsilicone oil at one end and a hydrogen content of 0.19%. 20g of 0.038% 40cs hydrogen-terminated polydimethylsiloxane at both ends, 1.5g of polyhydrogen-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com