A rock bolter that collects coal mine mining, support and transportation in parallel and fast operation

A bolter rig and rapid operation technology, which is applied to the installation of bolts, drilling equipment, mining equipment, etc., can solve the problems of low tunneling efficiency, unbalanced support, tedious and time-consuming machine adjustment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

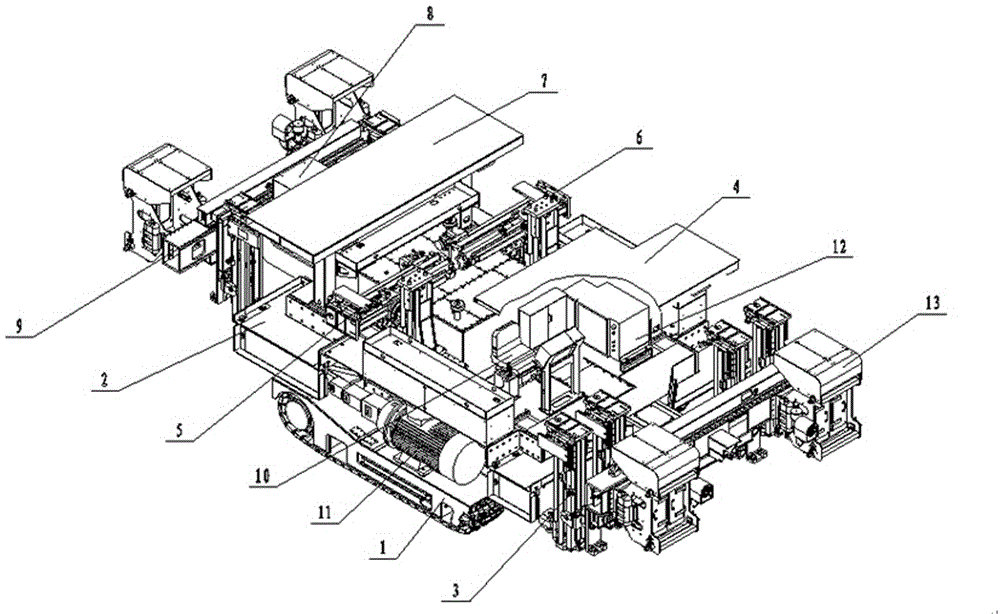

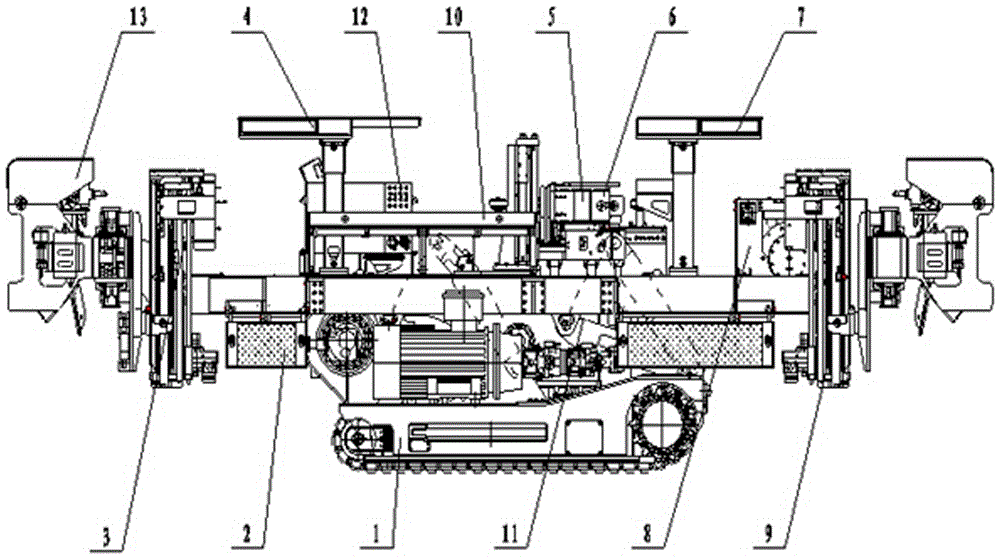

[0034] A bolt drill carriage that integrates coal mining, support and transportation parallel and fast operations, such as figure 1 , 2 As shown in 3, the crawler-walking anchor rig includes a crawler-walking chassis 1, a working platform 2, a front anchor guard 3 installed on the working platform, a front roof 4, a left side anchor guard 5, and a right side anchor guard 6, The rear ceiling 7, cable winding device 8, rear anchor protection 9, hydraulic system 11, electrical system 12 and dust removal system 13, the specific structure is as follows:

[0035] 1. Crawler walking straddle chassis

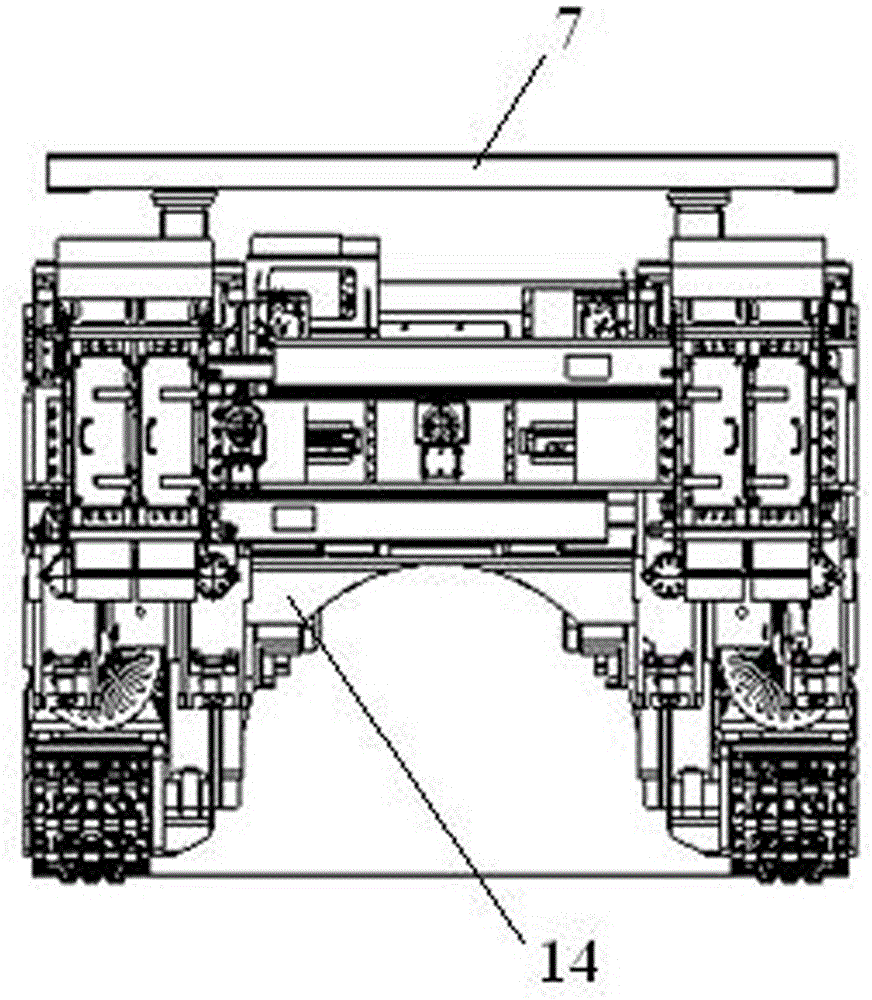

[0036] Such as Figure 4 As shown, the structure of the crawler-type chassis 1 includes an intermediate frame 14, a right track frame 15, a left track frame 18, a track chain 20, a driving device 21, and a support arm assembly 23. The intermediate frame 14 is an arched s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com