A kind of anti-freeze lng heat exchange method and device

A thermal method, anti-freezing technology, applied in indirect heat exchangers, heat exchanger shells, heat exchange equipment, etc., can solve the problems of condensation, large selection of conventional heat exchange media, etc., to achieve broad application prospects and save equipment costs and power consumption, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

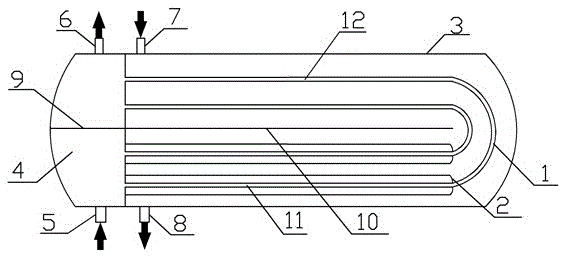

Embodiment 1

[0025]In this embodiment, LNG at 2 bar, -162°C, and 100 kg / h is used as the gasification task, and water at 2 bar, 25° C., and 950 kg / h is used as the conventional heat exchange medium. 2bar, -162°C, 100kg / h LNG enters the lower part of the pipe box 4 from the LNG inlet 5, and then enters the LNG gasification section 11 at the lower part of the heat exchanger. After heating, the temperature rises and gasifies into gaseous natural gas at -70°C, and then enters the NG heating section 12 on the upper part of the heat exchanger to exchange heat with 2bar, 25°C, 950kg / h water in the shell 3, and heats up to -10°C to enter the tube box 4 The upper part flows out from the natural gas outlet 6 to complete the gasification process; the C3C4 mixture gas in the annulus of the casing 2 exchanges heat with the LNG in the LNG gasification section 11 to cool down and condenses into a C3C4 mixture liquid, which drops to the bottom of the annulus. Then through the outer tube wall of the casing...

Embodiment 2

[0027] In this example, LNG at 2 bar, -162°C, and 100 kg / h is used as the gasification task, and 30% ethylene glycol aqueous solution at 2 bar, 25°C, and 850 kg / h is used as the conventional heat exchange medium. 2bar, -162°C, 100kg / h LNG enters the lower part of the pipe box 4 from the LNG inlet 5, and then enters the LNG gasification section 11 at the lower part of the heat exchanger. After heating, the temperature rises to gaseous natural gas at -70°C, and then enters the NG heating section 12 on the upper part of the heat exchanger to exchange heat with the 30% ethylene glycol aqueous solution of 2bar, 25°C, 850kg / h in the shell 3, and heats up to - 10°C enters the upper part of the tube box 4, and flows out from the natural gas outlet 6 to complete the gasification process; the C3C4 gas in the annular gap of the casing 2 exchanges heat with the LNG in the LNG gasification section 11 to cool down and condenses into a C3C4 liquid, and drops to the ring The bottom of the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com