Efficient GaN-based LED coupled to plasmon and manufacturing method thereof

A plasma and exciton technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems such as influence, improve near-field coupling efficiency, improve SPP wavelength excitation consistency and controllability, and improve device internal quantum The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to achieve the above object, the technical scheme adopted in the present invention is:

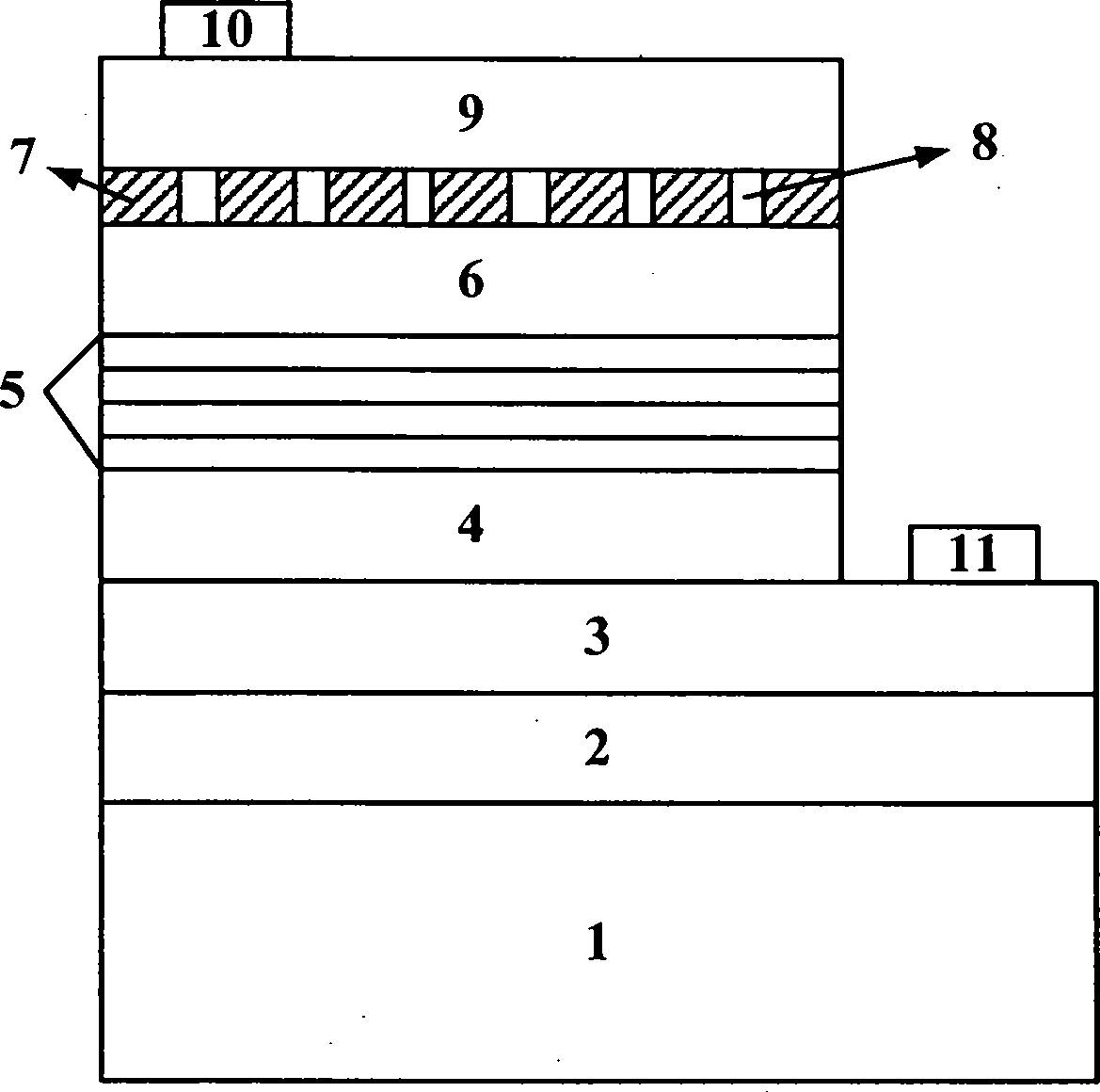

[0030] A high-efficiency GaN-based LED coupled with plasmons (as attached figure 1 Shown), its preparation method specifically comprises the following steps:

[0031] (1) The GaN-based LED is grown on a sapphire substrate by metal-organic chemical vapor deposition;

[0032] (2) In an environment of 550°C, grow a GaN nucleation layer with a thickness between 23nm and 27nm on a sapphire substrate;

[0033] (3) Raise the temperature to 1020°C, and grow a GaN undoped layer and an n-type GaN layer with a thickness between 1900nm and 2100nm, respectively;

[0034] (4) Lower the temperature to 770°C and re-grow InGaN / GaN multiple quantum wells with a cycle number of 4-6;

[0035] (5) Raise the temperature to 970°C, and re-grow a p-type GaN ohmic contact layer with a thickness between 27nm and 33nm;

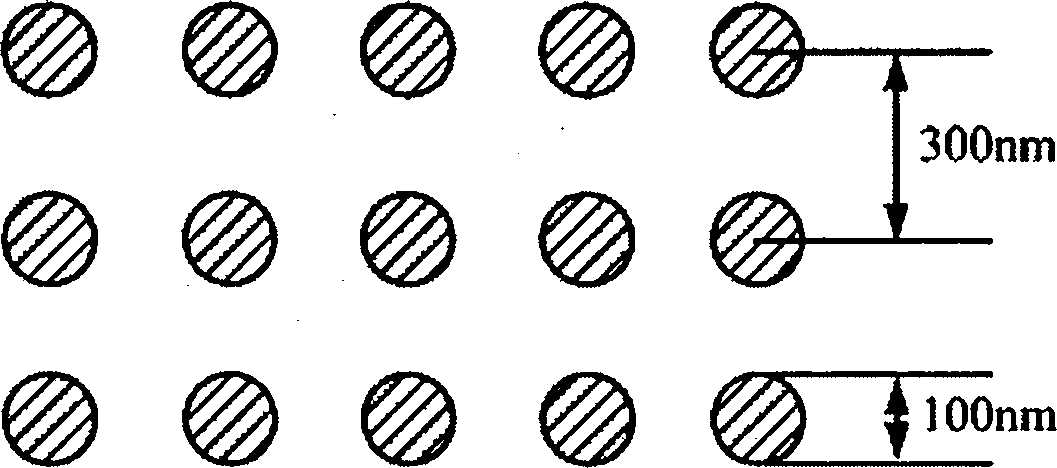

[0036] (6) On the p-type GaN, an Ag layer is prepared by using an electron be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com