Metal plasmon coupling luminescence enhancement silicon substrate LED and manufacturing method thereof

A metal plasma and luminescence enhancement technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of large differences in properties such as plasmon resonance frequency SPP absorption and scattering, etc., and achieve good SPP wavelength excitation consistency and controllability performance, improve the quantum efficiency of the device, and improve the effect of near-field coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the drawings and embodiments.

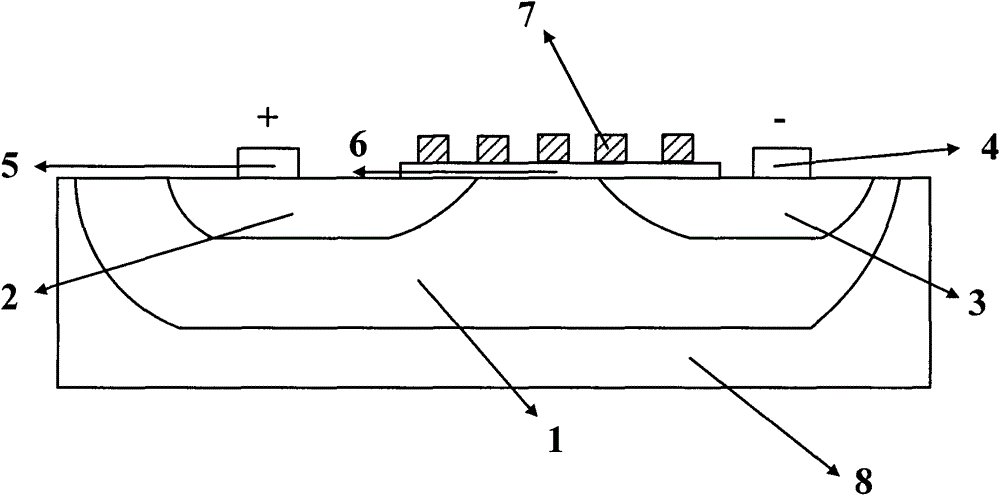

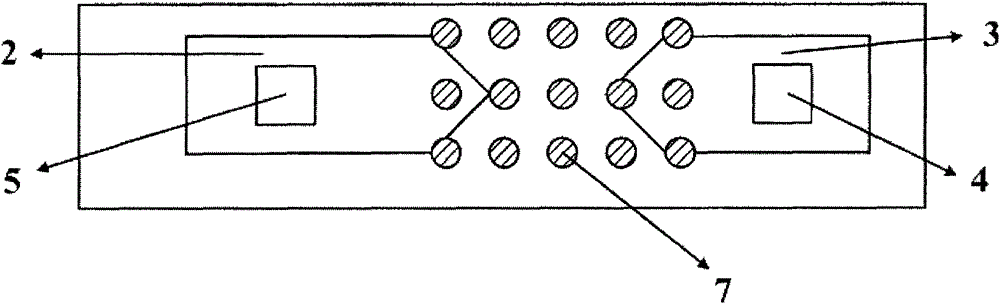

[0039] The LED produced by the present invention is prepared by referring to the CMOS process to prepare a wedge-shaped electrode shallow well electroluminescent PN junction. + A layer of SiO is prepared on the N-well light-emitting junction 2 . In SiO 2 On top, a layer of metal photonic crystal is prepared. As attached figure 1 And figure 2 Shown.

[0040] The invention refers to the standard integrated circuit process, and designs the plasmon coupling to enhance the light emission of the device. The PN junction of the device is designed in a shallow well, and the carriers are located on the surface of the device to recombine, reducing the absorption of light radiation by silicon-based materials. PMOS and NMOS source and drain region ion implantation processes are used to inject P+ and N+ wedge-shaped electrodes to generate a PN junction to inject a strong electric fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com