Wolfberry soluble dietary fiber and preparation method thereof

A dietary fiber and soluble technology, which is applied in the field of biochemical engineering, can solve the problems not involved in residue treatment, etc., and achieve the effect of excellent cholesterol adsorption capacity, simple process and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

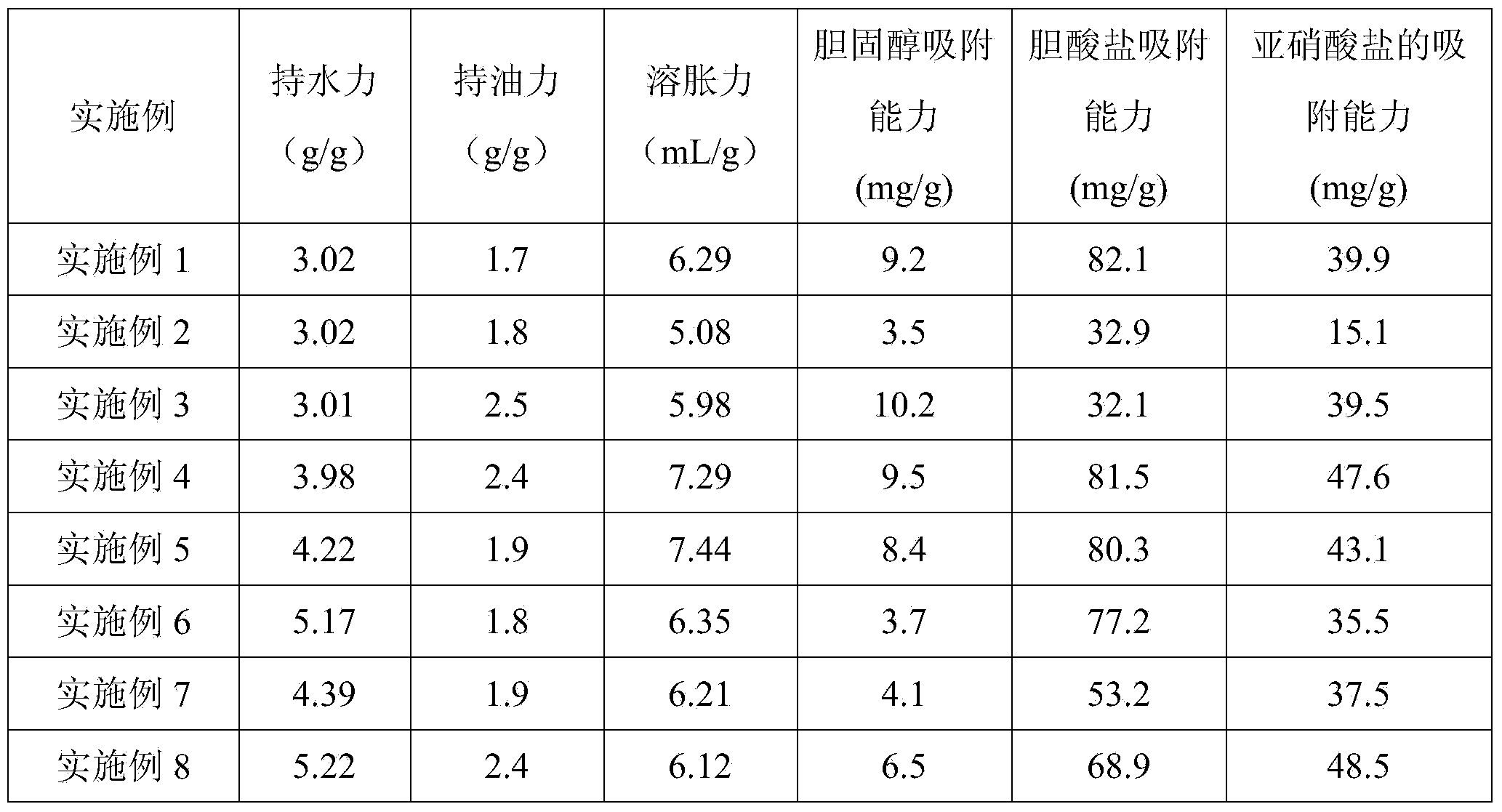

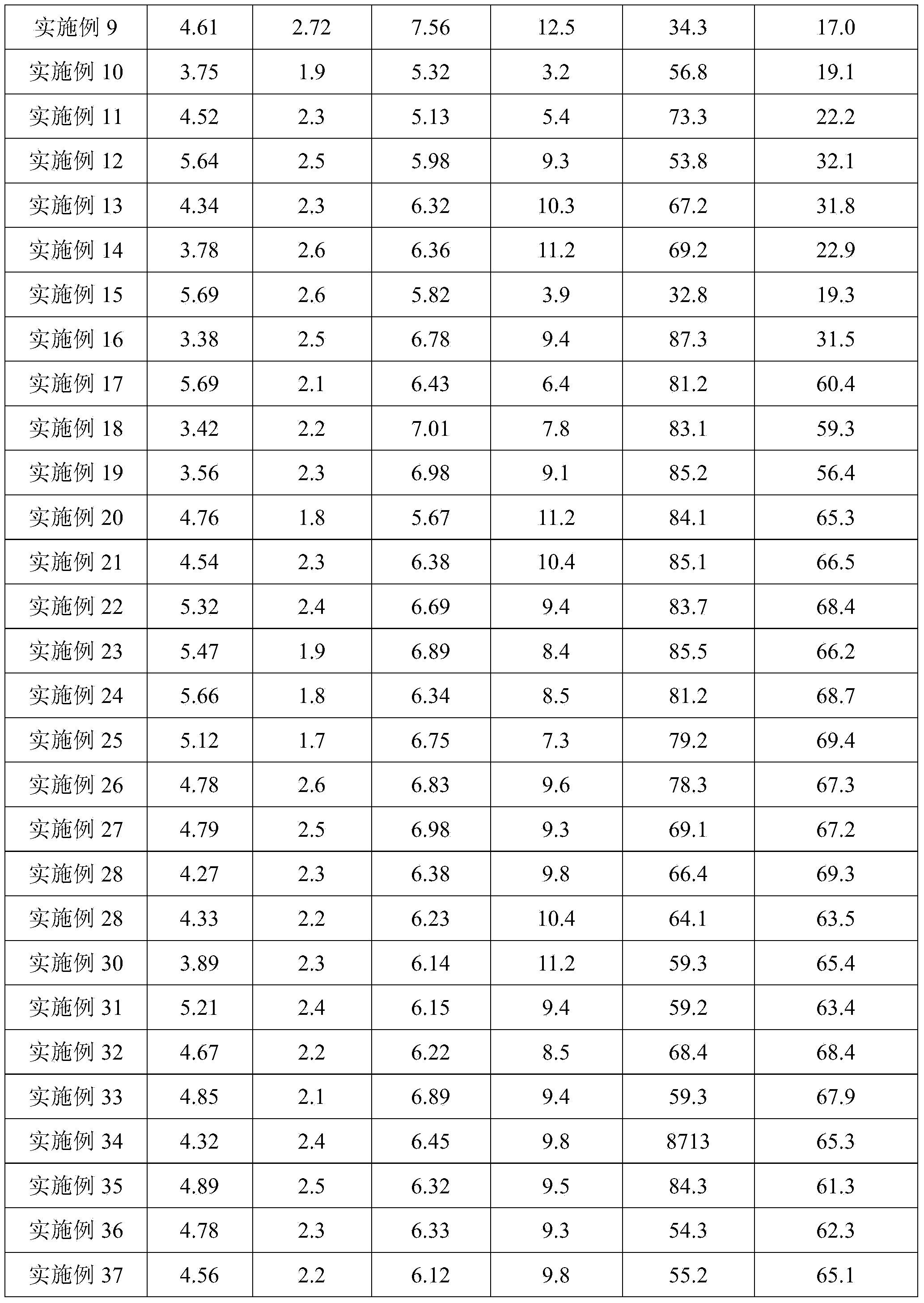

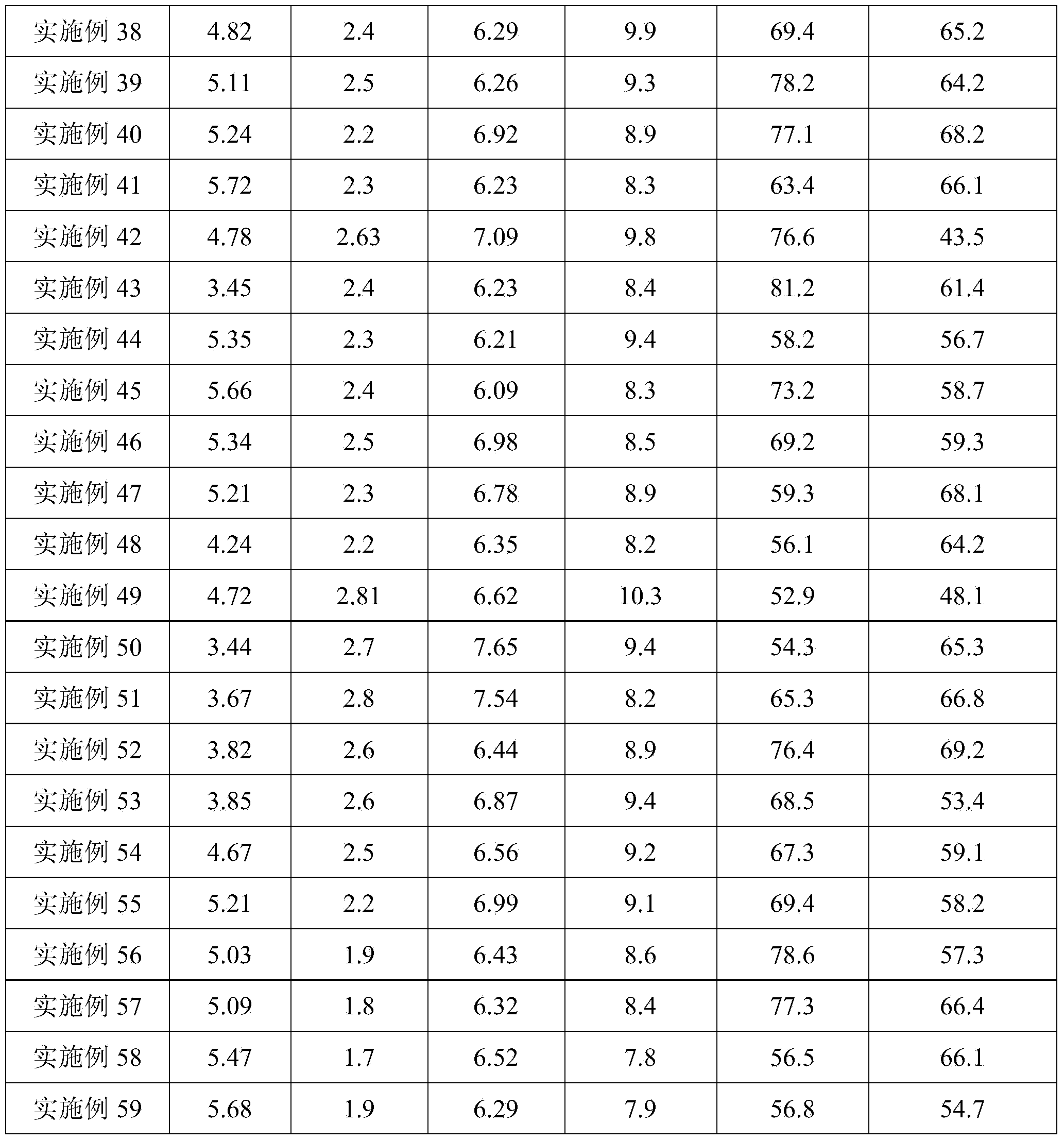

Examples

Embodiment 1

[0087] (1) Raw materials: Lycium barbarum residue produced from the production of Lycium barbarum alcohol extract;

[0088] (2) Acid extraction: add 5 times the weight of 0.7% hydrochloric acid to soak in wolfberry residue, then extract, the extraction time is 10h; solid-liquid separation, collect supernatant;

[0089] (3) Concentration: Concentrate the supernatant until the solid content is 10%;

[0090] (4) Precipitation: Precipitate the above concentrate with 100% ethanol;

[0091] (5) Drying: the precipitate is cleaned with 75% ethanol; the washed precipitate is dried, and the dried material is pulverized or ground to obtain soluble wolfberry dietary fiber.

Embodiment 2

[0093] (1) Raw materials: Lycium barbarum residue produced in the production of wolfberry fermented wine;

[0094] (2) Acid extraction: add 10% citric acid of 35 times of weight to soak in wolfberry residue, then extract, extraction time is 0.5; solid-liquid separation, collect supernatant;

[0095] (3) Concentration: Concentrate the supernatant until the solid content is 65%;

[0096] (4) Precipitation: Precipitate the above concentrate with 50% ethanol;

[0097] (5) Drying: the precipitate is washed with 100% ethanol; the washed precipitate is dried, and the dried material is pulverized or ground to obtain soluble wolfberry dietary fiber.

Embodiment 3

[0099] (1) Raw materials: Lycium barbarum residue produced from producing Lycium barbarum polysaccharide, Lycium barbarum residue produced from producing Lycium barbarum fruit wine, Lycium barbarum residue mixture produced from producing Lycium barbarum fermented wine;

[0100] (2) acid extraction: add 0.1% hydrochloric acid, acetic acid, citric acid, malic acid, mixed acid soaking of 10 times of weight in wolfberry residue, then extract, extraction time is 2; solid-liquid separation, collect supernatant;

[0101] (3) Concentration: Concentrate the supernatant until the solid content is 30%;

[0102] (4) Precipitation: Precipitate the concentrate with a concentration of 70% ethanol;

[0103] (5) Drying: the precipitate is washed with 85% ethanol; the washed precipitate is dried, and the dried material is pulverized or ground to obtain soluble wolfberry dietary fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com