Novel cigarette heater provided with aerogel heat-insulating layer

A technology of aerogel and thermal insulation layer, which is applied in the direction of tobacco, tobacco pipe, application, etc., to achieve the effect of improving the utilization rate, reducing the feel temperature, and slowing down the heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

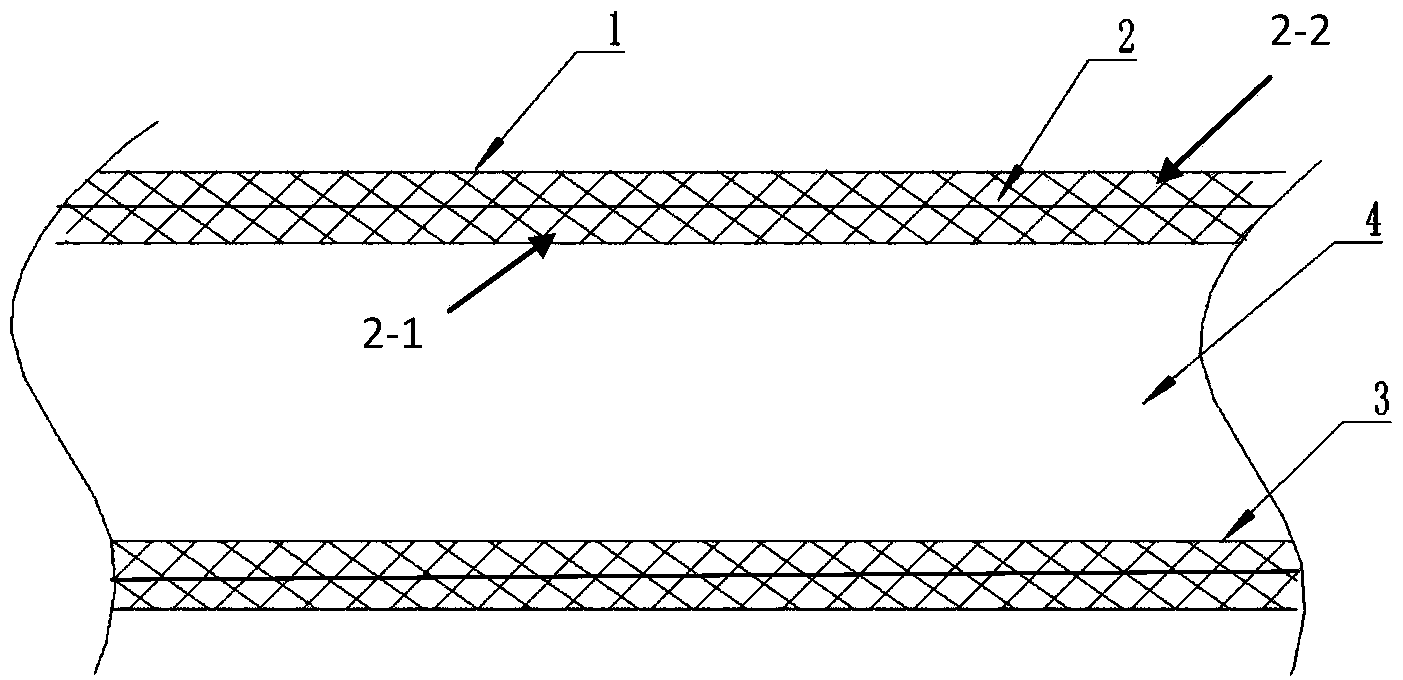

[0026] Use as figure 1 The novel cigarette heater with an aerogel heat insulation layer is shown, which includes a housing 1, a heating element 3, a heating cavity 4 formed by the heating element 3, and a heating element 3 and the housing 1 Between the insulation layer 2. The aerogel material used in the thermal insulation layer is bridged silsesquioxane aerogel, and the application form is flexible felt. The aerogel in the outer layer of the thermal insulation layer is filled with 2% volume fraction of montmorillonite- Fatty acid complex. The thickness of the heat insulation layer is 5 mm, and when the temperature of the heating element reaches 600°C, the temperature of the shell is 45°C.

Embodiment 2

[0028] Use as figure 1 The novel cigarette heater with an aerogel heat insulation layer is shown, which includes a housing 1, a heating element 3, a heating cavity 4 formed by the heating element 3, and a heating element 3 and the housing 1 Between the insulation layer 2. The aerogel material used in the heat insulation layer is resorcinol-formaldehyde aerogel with quartz fiber mixed therein, the application form is particles, and a layer of aluminum foil is wrapped on the surface of the aerogel material, and the heat insulation layer is outside The layer of aerogel is filled with 5% by volume of polyethylene glycol 2000. The thickness of the heat insulation layer is 8 mm, and when the temperature of the heating element reaches 600°C, the temperature of the shell is 40°C.

Embodiment 3

[0030] Use as figure 1 The novel cigarette heater with an aerogel heat insulation layer is shown, which includes a housing 1, a heating element 3, a heating cavity 4 formed by the heating element 3, and a heating element 3 and the housing 1 Between the insulation layer 2. The aerogel material used in the heat insulation layer is silica aerogel, and the application form is powder. A layer of aluminum foil is coated on the surface of the aerogel material, and the aerogel on the outer layer of the heat insulation layer is filled with 10% volume fraction of oleic acid. The thickness of the heat insulation layer is 2 mm, and when the temperature of the heating element reaches 600°C, the temperature of the shell is 38°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com