Production line of feed premix

A premix and production line technology, applied in the direction of mixers, mixers with rotating stirring devices, dissolution, etc., can solve problems such as the inability to guarantee the long-term stability of production quality, hidden dangers to the health of production workers, and low preparation efficiency. The effect of flexible site selection, high degree of automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

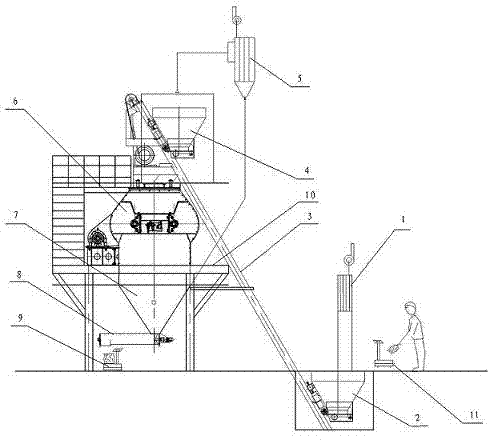

[0010] Such as figure 1 As shown, according to the actual situation of the manufacturer, select the installation location, then use metal materials to build a working platform 10 with a height of about 2.7 meters, then install the horizontal double-shaft mixer 6 on the working platform 10, and place it on the working platform 10. A mixing port 4 is arranged above, and a pit for placing the collecting hopper 2 is arranged underground on one side, and an automatic feeder 3 is provided for conveying between the pit and the mixing port 4, and on one side of the pit A feeding weighing scale 11 is placed on the ground; a pulse dust collector 1 is arranged above the collecting hopper 2, and a pulse dust collector 5 is arranged above the mixing port 4. A material buffer hopper 7 is set below the working platform 10, a screw conveying auger 8 is arranged at its discharge port, and a manual packaging weighing scale 9 is placed on the ground directly below the auger outlet. When impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com