Preparation method for environmentally-friendly automobile interior material

An environment-friendly, automotive interior technology, applied in the field of preparation, can solve the problems of small coverage of health care materials, low production efficiency, single function, etc., and achieve the effect of lasting and effective play, improving production efficiency, and increasing load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

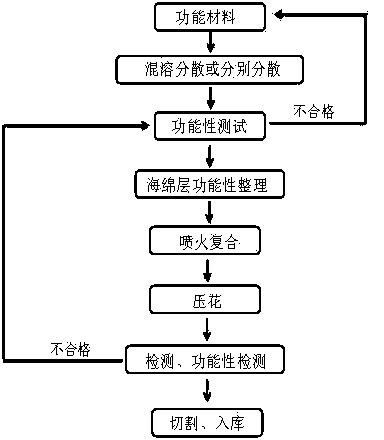

[0025] 1) Functional material finishing solution: modify the antibacterial and deodorant finishing agent and negative ion finishing agent to mix and mix, stir evenly, then disperse into the aqueous solution, and stir evenly. The antibacterial and deodorant finishing agent is nano-titanium dioxide finishing agent, negative ion finishing The active ingredient is tourmaline stone.

[0026] 2) Functional finishing: The sponge interlayer of automotive interior materials is selected for functional finishing. After the sponge is pad-rolled with the functional finishing liquid, it is directly put into the oven for drying without dehydration. winding.

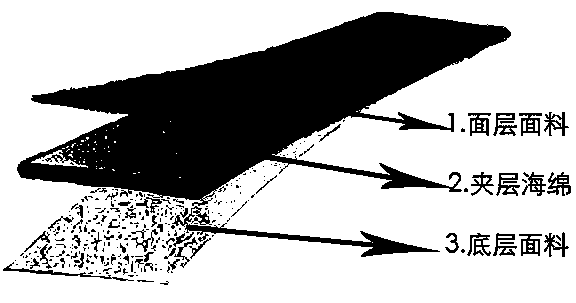

[0027] 3) Fire-breathing lamination: feed the sponge layer, surface fabric, and bottom fabric into the fire-breathing lamination machine at the same time. After the instantaneous high temperature of the flame, the surface of the sponge layer melts. The bottom fabrics are combined and then wound up for later use.

[0028] 4) Embossing:...

Embodiment 2

[0034] 1) Functional material finishing solution: modify the antibacterial and deodorant finishing agent and negative ion finishing agent to mix and mix, stir evenly, then disperse into the aqueous solution, and stir evenly. The antibacterial and deodorant finishing agent is a quaternary ammonium salt antibacterial finishing agent , The active ingredient of negative ion finishing agent is quantum energy powder.

[0035] 2) Functional finishing: The sponge interlayer of automotive interior materials is selected for functional finishing. After the sponge is pad-rolled with the functional finishing liquid, it is directly put into the oven for drying without dehydration. winding.

[0036] 3) Fire-breathing lamination: feed the sponge layer, surface fabric, and bottom fabric into the fire-breathing lamination machine at the same time. After the instantaneous high temperature of the flame, the surface of the sponge layer melts. The bottom fabrics are combined and then wound up for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com