Method for coupling MTO process and naphtha and propane cracking progressive separation process

A technology of sequential separation and naphtha, applied in the direction of distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of low benefit of raw material products, large investment, unreasonable process design, etc., and achieve reduction The effect of energy consumption, investment reduction and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

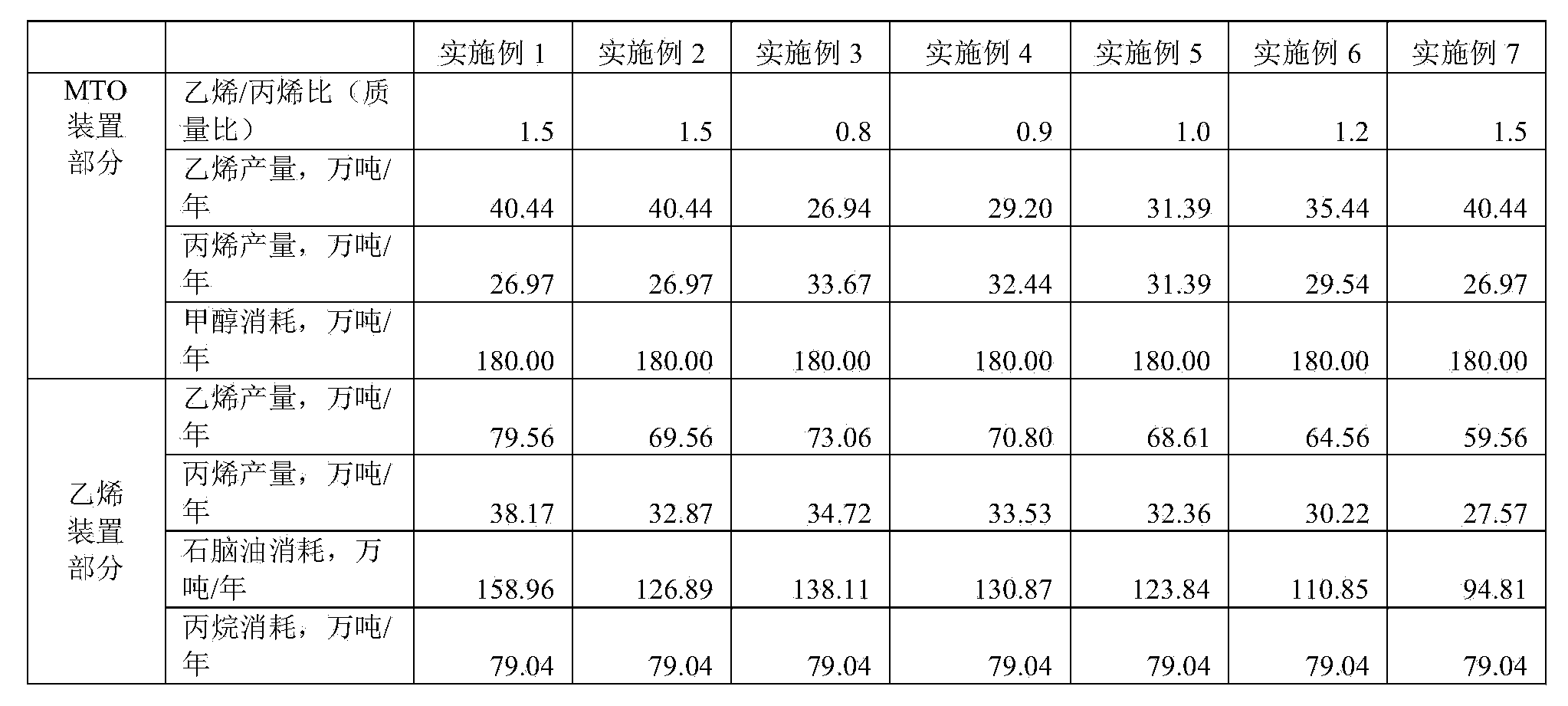

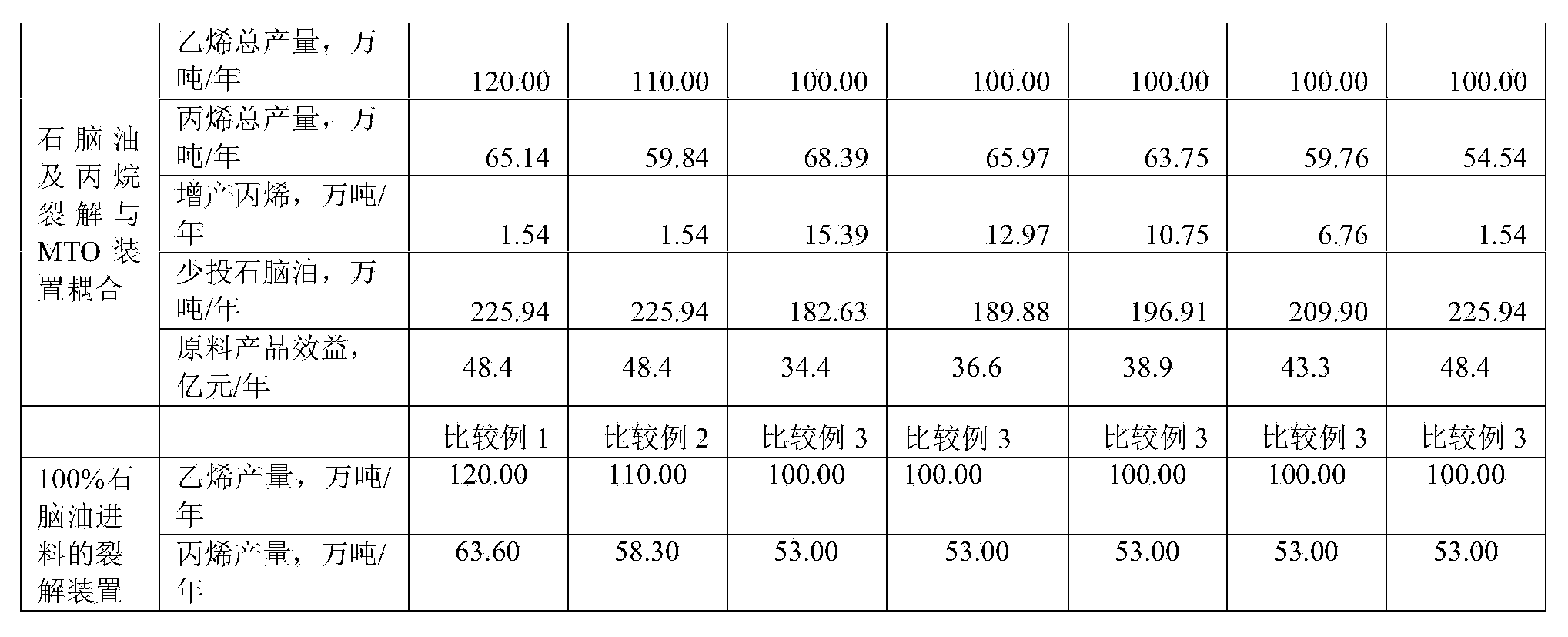

[0022] The naphtha and propane steam cracking ethylene unit adopts a sequential separation process. The ethylene production capacity is 1.2 million tons / year, the propane raw material feed is 790,400 tons / year, and the mass ratio of propylene to ethylene in the cracking gas is 0.53. New The methanol processing scale of the MTO unit is 1.8 million tons per year, and the mass ratio of ethylene to propylene in the MTO product gas is 1.5. After the product gas of the MTO unit is separated and compressed in the rough separation tower, part of C3 and all lighter components are sent to the five-stage compression outlet of the cracking unit, and enter the cold box of the cracking unit together with the cracking gas; the product gas of the MTO unit is separated in the depropanizer Finally, the tower bottom liquid and the naphtha steam cracking ethylene plant's depropanizer bottom liquid enter the ethylene plant's debutanizer for separation. Using the coupling method of the present inve...

Embodiment 2

[0026] According to the conditions and steps described in Example 1, the ethylene production capacity of the naphtha and propane steam cracking ethylene plant is 1.1 million tons per year, and the specific data are shown in Table 1. Compared with Comparative Example 2, the input of naphtha is reduced by 2.2594 million tons / year, and the production of propylene is increased by 15,400 tons / year.

Embodiment 3

[0030] According to the conditions and steps described in Comparative Example 1, the ethylene production capacity of the naphtha and propane steam cracking ethylene plant is 1 million tons per year, and the mass ratio of ethylene to propylene in the product gas of the newly added MTO plant is 0.8. Using the coupling method described in the present invention, the operating conditions of the crude separation tower are: temperature is -20°C, and pressure is 0.6MPaG. See Table 1 for specific data. Compared with Comparative Example 3, 1.8263 million tons of naphtha was reduced per year, and propylene production was increased by 153.9 thousand tons per year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com