Heavy-duty anti-corrosion coating and painting method thereof

A heavy-duty anti-corrosion and coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of unsatisfactory anti-corrosion performance and short protection period of heavy-duty coatings, and achieve strong seawater corrosion resistance and use long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

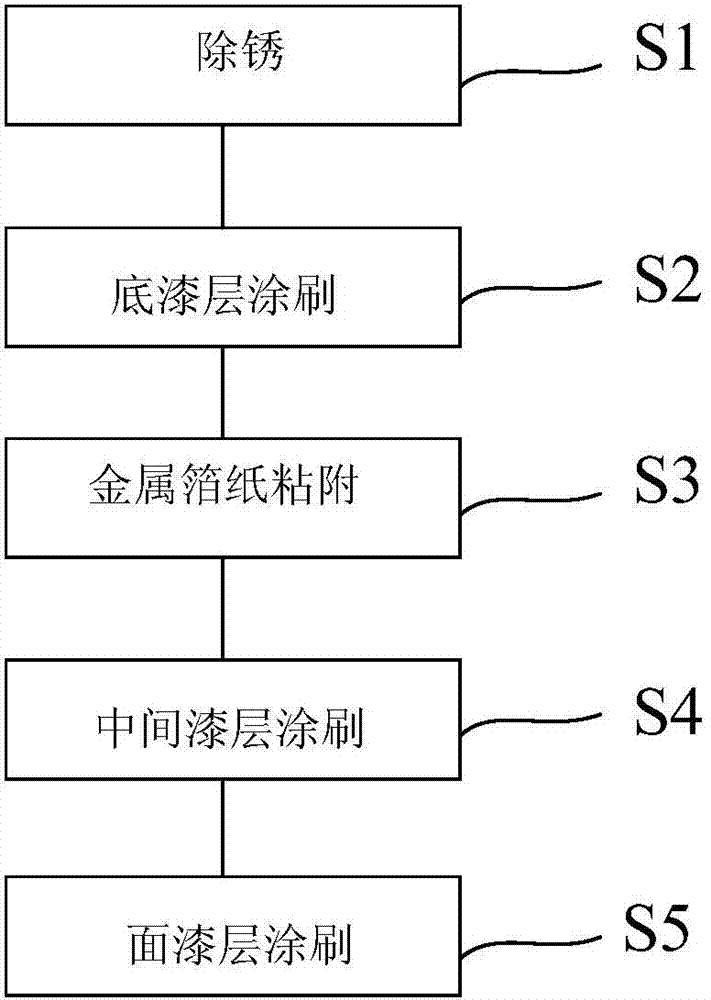

Method used

Image

Examples

Embodiment 1

[0030] Get 30g epoxy resin, 30g phenolic resin, 6g epoxy thinner (acetone), 6g phenolic thinner (alcohol), 5g epoxy curing agent (ethylenediamine) and 5g phenolic curing agent (benzenesulfonyl chloride), then Mix epoxy resin with epoxy thinner and epoxy curing agent, mix phenolic resin with phenolic thinner and phenolic curing agent, and finally mix the two materials again to form the main ingredient; take 5g of 200 mesh quartz powder and 5g of polytetrafluoroethylene Ethylene is mixed to form an additive; 3.5g of dibutyl ester and 4.5g of fumed silica are mixed to form an accelerator, and the main material, additive and accelerator are mixed and prepared at room temperature (about 25°C) to form a heavy-duty anti-corrosion coating.

[0031] Apply the paint on the surface of the iron pipe, seal both ends of the iron pipe to prevent seawater from entering the interior of the iron pipe, then soak the iron pipe in seawater at a temperature of 20°C, and soak it for 2 hours Take it ...

Embodiment 2

[0035] Get 25g epoxy resin, 35g phenolic resin, 5g epoxy thinner (acetone), 5g phenolic thinner (alcohol), 6g epoxy curing agent (ethylenediamine) and 6g phenolic curing agent (benzenesulfonyl chloride), then Mix epoxy resin with epoxy thinner and epoxy curing agent, mix phenolic resin with phenolic thinner and phenolic curing agent, and finally mix the two materials again to form the main ingredient; take 4g of 400 mesh quartz powder and 4.5g polytetrafluoroethylene Mix vinyl fluoride to form an additive; take 4g of dibutyl ester and 4.5g of gaseous carbon dioxide to form an accelerator, mix the main material, additive and accelerator, and prepare at room temperature (about 25°C) to form a heavy-duty anti-corrosion coating.

[0036] Apply the paint on the surface of the iron pipe, seal both ends of the iron pipe to prevent seawater from entering the interior of the iron pipe, then soak the iron pipe in seawater at a temperature of 20°C, and soak it for 2 hours Take it out, le...

Embodiment 3

[0038] Get 30g epoxy resin, 34g phenolic resin, 5g epoxy thinner (acetone), 4g phenolic thinner (alcohol), 6g epoxy curing agent (ethylenediamine) and 3g phenolic curing agent (benzenesulfonyl chloride), then Mix epoxy resin with epoxy thinner and epoxy curing agent, mix phenolic resin with phenolic thinner and phenolic curing agent, and finally mix the two materials again to form the main ingredient; take 4g of 300 mesh quartz powder and 4.5g polytetrafluoroethylene Mix vinyl fluoride to form an additive; take 4g of dibutyl ester and 4.5g of gaseous carbon dioxide to form an accelerator, mix the main material, additive and accelerator, and prepare at room temperature (about 25°C) to form a heavy-duty anti-corrosion coating.

[0039]Apply the paint on the surface of the iron pipe, seal both ends of the iron pipe to prevent seawater from entering the interior of the iron pipe, then soak the iron pipe in seawater at a temperature of 20°C, and soak it for 2 hours Take it out, let...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com