Wear-resistant coating and preparation method thereof

A technology of wear-resistant coatings and additives, applied in the field of coatings, can solve the problems of lack of wear-resistant coatings and achieve the effects of increased UV resistance, superior insulation, and regular shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

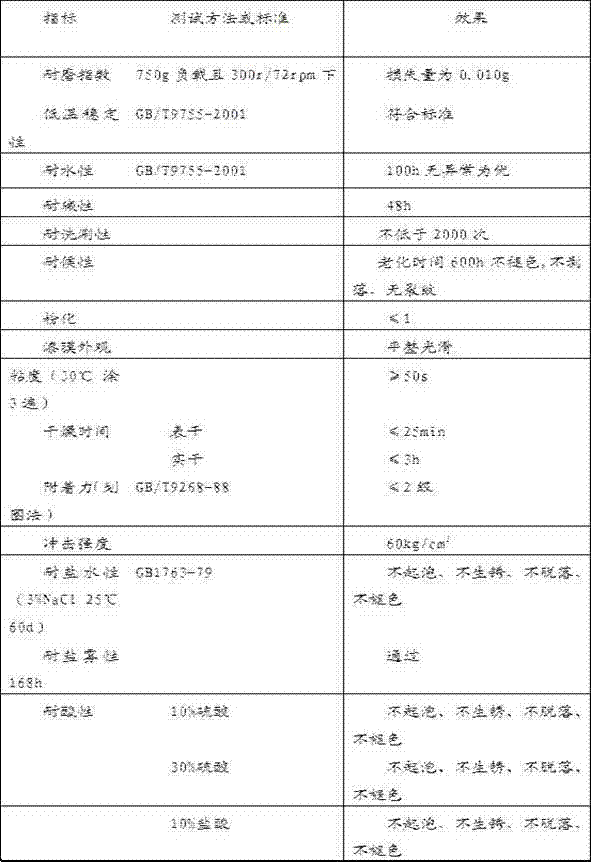

Image

Examples

Embodiment 1

[0030] A kind of wear-resisting coating of the present invention, comprises the following composition by weight percentage:

[0031] Unsaturated polyester varnish 43%

[0032] Mineral spirit 30%

[0033] Hardener 8%

[0034] Auxiliary 6%

[0036] Silicone resin 2%.

[0037] The use of silicone resin in powder coatings can improve its heat resistance and weather resistance, but the use of silicone resin alone has problems such as high price and poor adhesion to the substrate. Therefore, silicone resins are often used to modify other organic resins, which can combine the advantages of silicone resins and other organic resins to make up for their shortcomings, improve the weather resistance and heat resistance of the paint film, and obtain powder coatings with excellent performance;

[0038] Ultra-fine wax powder has a very low melting point and is not easy to disperse. Silicon material or sili...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is: a kind of wear-resisting coating, it is characterized in that comprising the following composition by weight percentage:

[0046] Unsaturated polyester varnish 45%

[0047] Mineral spirit 32%

[0048] Curing agent 9%

[0049] Auxiliary 6.5%

[0050] Wax powder 1.5%

[0051] Silicone resin 3%.

[0052] The auxiliary agent is selected from a combination of polyacrylate polymers, polymer silicones, and fluorine-modified acrylate polymers.

[0053] The curing agent is composed of 93-97wt% polyamide curing agent and 3-7wt% m-phenylenediamine curing agent.

[0054] The wax powder is ultra-fine wax powder reaching micron level.

[0055] Described solvent oil is No. 200 solvent oils.

[0056] The preparation method of wear-resistant coating of the present invention, comprises the steps:

[0057] (1) At room temperature of 28°C, weigh the above components by weight, mix...

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 1 is: a kind of wear-resisting coating, it is characterized in that comprising the following composition by weight percentage:

[0062] Unsaturated polyester varnish 47%

[0063] Mineral spirit 35%

[0064] Curing agent 10%

[0065] Auxiliary 7%

[0066] Wax powder 2%

[0067] Silicone resin 4%.

[0068] The auxiliary agent is selected from one or a combination of polymer silicone, fluorine-modified acrylate polymer or silicon dioxide auxiliary agent.

[0069] The curing agent is composed of 97wt% polyamide curing agent and 7wt% m-phenylenediamine curing agent.

[0070] Described solvent oil is No. 180 solvent oils.

[0071] The preparation method of wear-resistant coating of the present invention, comprises the steps:

[0072] (1) At room temperature of 30°C, weigh the above-mentioned components by weight, mix the emulsified silicone resin, additives, and wax powder, and stir wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com