Method for continuously producing wood granular fuel

A technology for wood pellets and production methods, which is applied to fuels, solid fuels, biofuels, etc., can solve the problems of difficult to control moisture content, different forms of wood chips, and poor yield and quality, achieve uniform moisture content, reduce operating costs, and thermal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

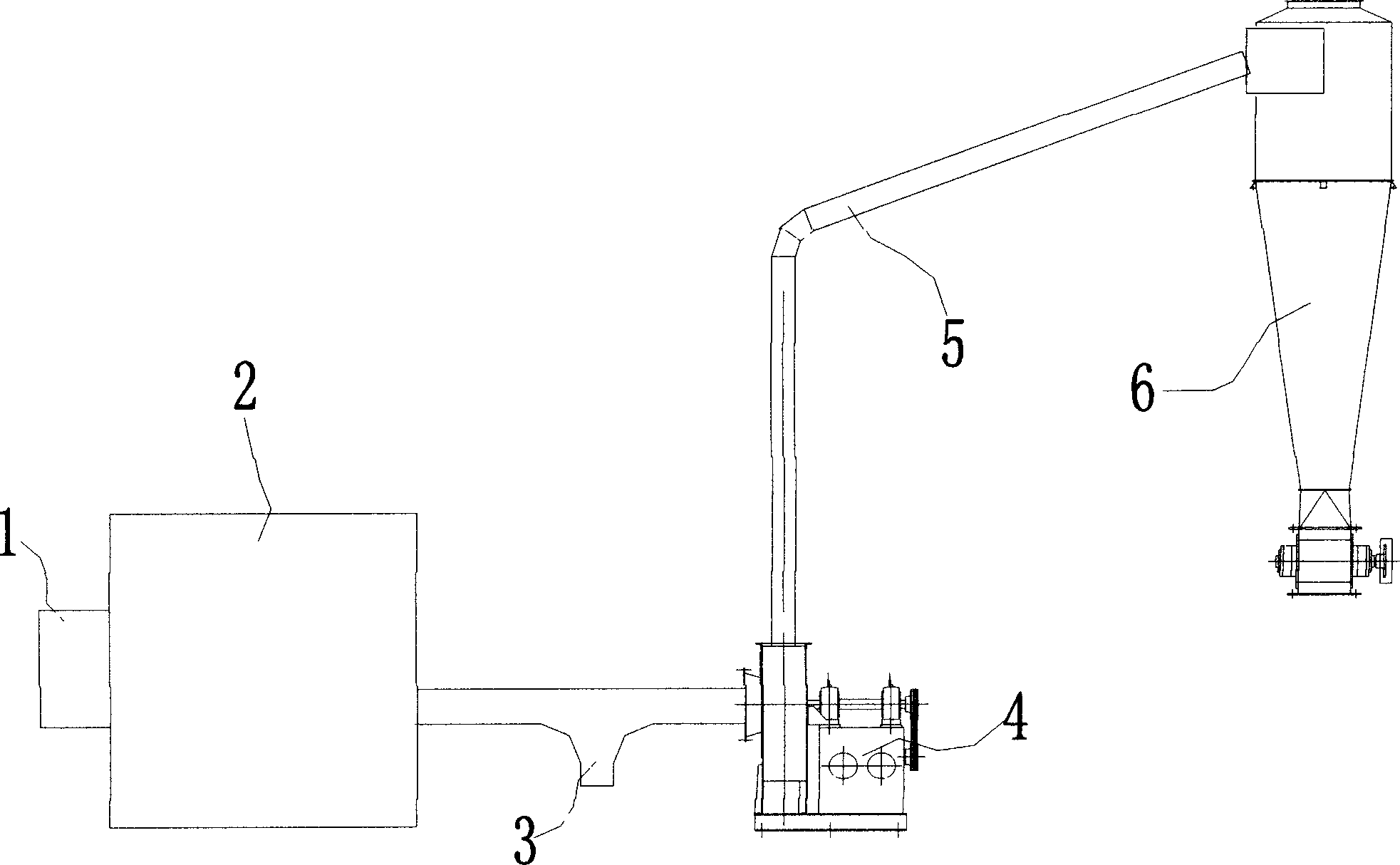

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the embodiments do not limit the protection scope of the present invention.

[0032] According to the operating principle of the granulator, the present invention makes full use of economic forests without felling indicators such as mango, coconut and lychee trees; wind falls rubber wood and normally renews the leftovers of rubber wood; wood processing residues (such as fingerboard skin, Slats, wood and bamboo cuttings, saw foam, broken veneer, wood core, wood shavings, wood blocks, leftovers, etc.) and various wastes such as branch wood of various felling index trees to form wood pellet fuel.

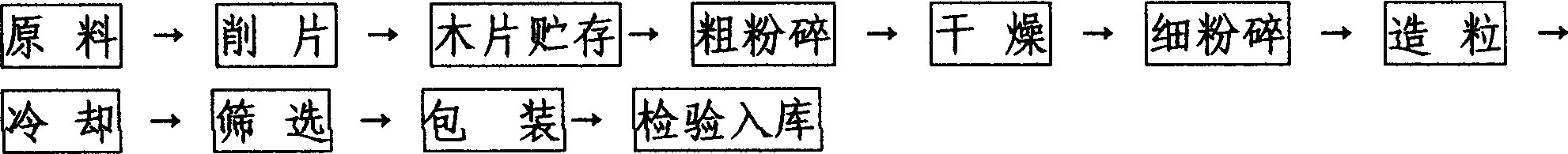

[0033] A method for continuous production of wood pellet fuel, such as figure 1 As shown, it includes the following steps:

[0034] (1) Material preparation process: the wooden raw material is chipped, and the length of the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com