Method and device for temperature control of hydraulic oil tank

A technology of temperature control device and hydraulic oil tank, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem of poor on-site temperature control effect, etc. Precise control and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

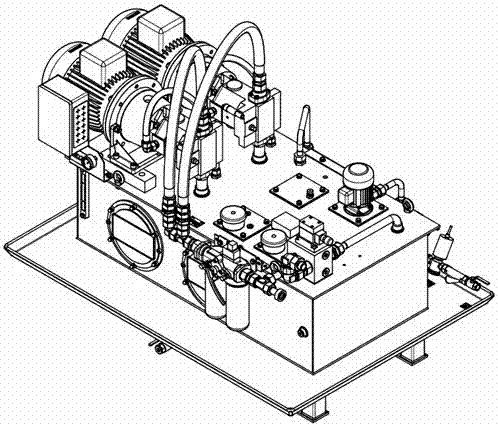

[0032] Embodiment 1: A hydraulic oil tank temperature control device, the temperature control device includes a temperature detection unit, a temperature processing unit and an execution unit, wherein the temperature detection unit transmits the detection data to the temperature processing unit, and the temperature processing unit transmits the processed execution command to the execution unit.

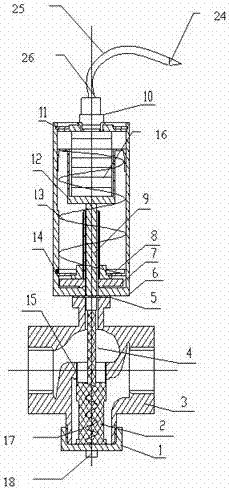

[0033] The temperature detection unit includes a probe 24, a connecting nut, a transfer pipe 25, a damping ring, and a protection spring 27, wherein the probe 24 is arranged on the head of the detection unit, and is connected with the transfer pipe 25 by welding, and the afterbody of the probe can be installed with The connecting nut is provided with a step, a sealing groove is placed on the step, and a lock nut is arranged on the outside of the step, so that it is not directly inserted into the fuel tank but is threaded at the part closest to the inlet circulation pipe of the cooler; ...

Embodiment 2

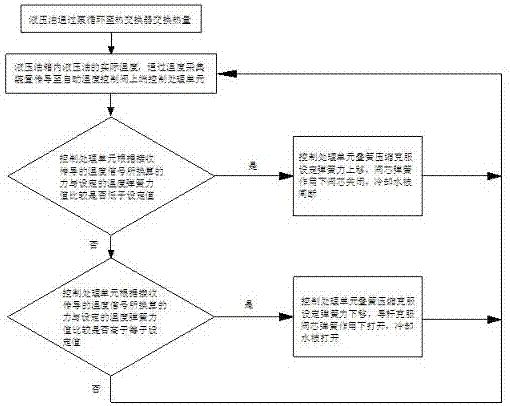

[0034] Example 2: see image 3 , Figure 4 , Figure 5-1 , Figure 5-2 , Figure 6 , Figure 7-1 , Figure 7-2 , as an improvement of the present invention, the temperature processing unit includes a force feedback alloy stack spring 16, a first support guide block 12, a pressure setting spring 13, a force transmission guide rod 9, a second support guide block 14, a support adjustment Round nut 8, adjusting stud 28, adjusting handle 7;

[0035] The force feedback alloy stack spring 16 is a force feedback element that rapidly expands or compresses proportionally through the detected temperature, the first support guide block 12, the pressure setting spring 13, the second support guide block 14, and the support adjustment The round nut 8, the adjusting stud 28, and the adjusting handle 7 form an initial pressure setting mechanism; by rotating the adjusting handle 7, the elastic force of the pressure setting spring 13 is overcome, and the adjusting stud 28 is driven to move...

Embodiment 3

[0037] Embodiment 3: see figure 2 , image 3 , as an improvement of the present invention, the adjustment handle 7 is provided with a concave-convex platform that is highly centered with the bottom of the outer cover and an octagonal structure that facilitates the adjustment of the pressure setting spring in a narrow space, and the opening between the structures is smaller than the opening of the outer cover Portion size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com