Energy-efficient heat supply furnace

A high-efficiency energy-saving heating furnace technology, which is applied to furnaces/stoves with hot water devices, household heating, heating systems, etc., can solve problems such as low heat utilization rate, insufficient fuel combustion, and waste of fuel. Achieve the effects of reducing the generation of waste residue, improving the utilization rate of heat energy, and improving the utilization rate of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

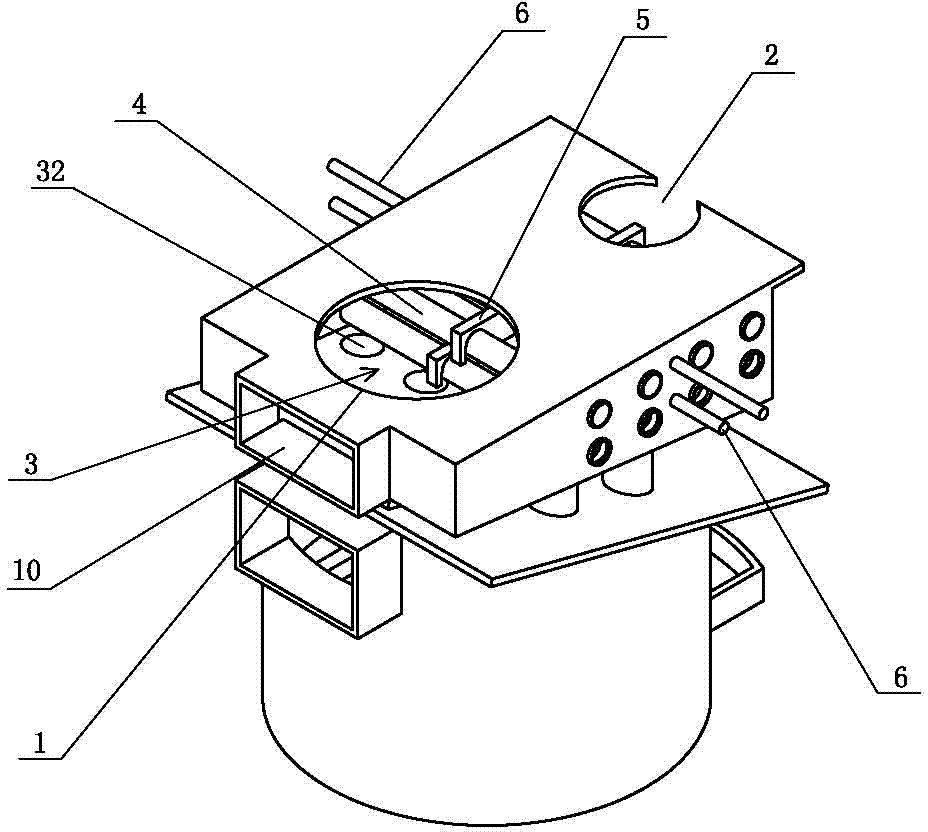

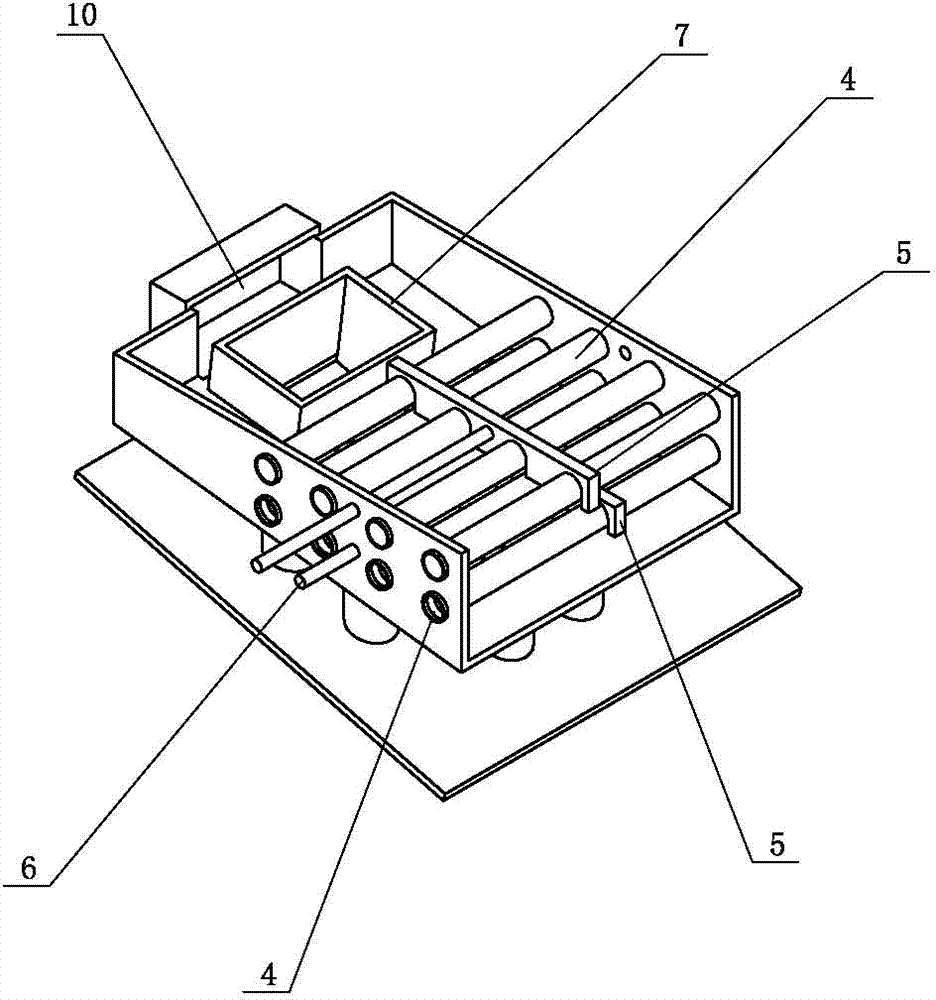

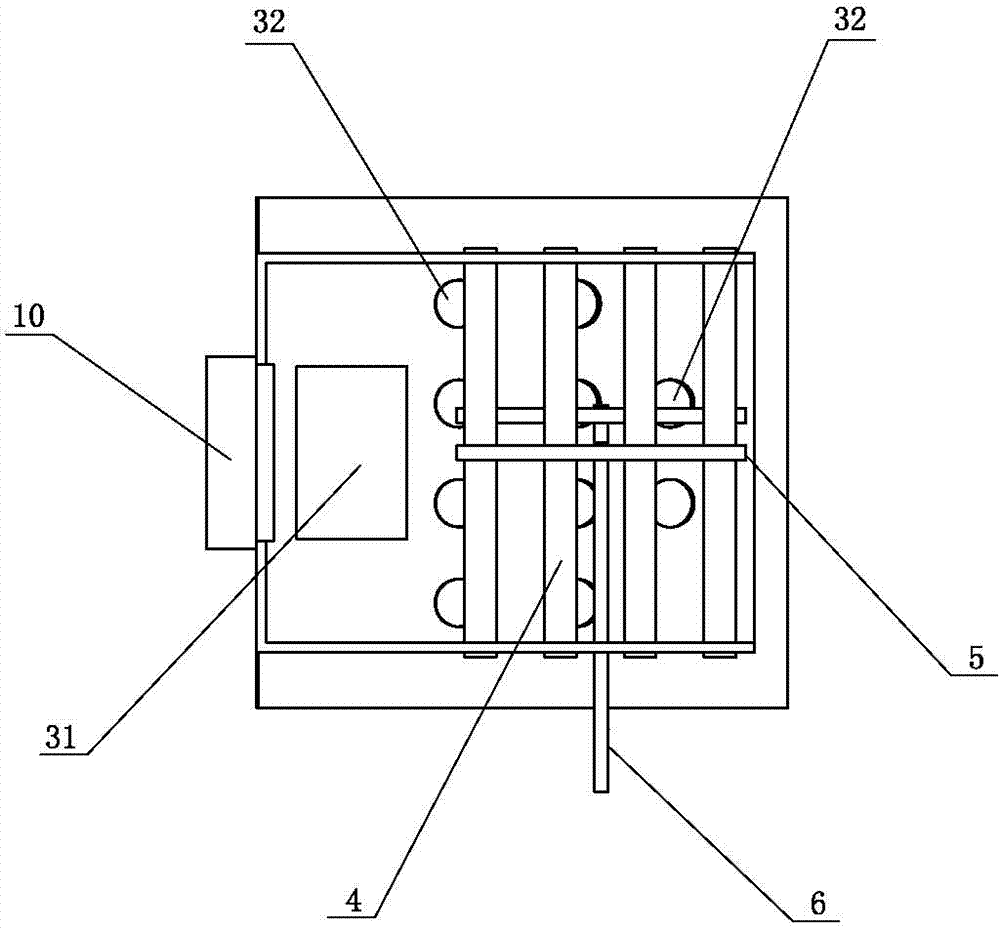

[0024] like Figures 1 to 6 As shown, a high-efficiency and energy-saving heating furnace includes a furnace body. One end of the furnace body top is provided with a stove port 1, and the other end is provided with a chimney connection port 2; It is a hollow closed water tank, located on the furnace 3 and below the stove mouth 1, and the main fire outlet 31 is set; on the upper part of the furnace 3, it runs through the peripheral wall of the furnace body in a horizontal direction, and there are two rows of warm water pipes 4, each of which are arranged in parallel. A dust-sweeping board 5 is all buckled on every row of warm water pipes 4; the bottom of the dust-sweeping board 5 is provided with four semicircular openings side by side at intervals, and these four openings are just stuck in four warm water pipes 4 tops, so that the dust-sweeping boards 5 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com