Anti-collision control method for leaves of multileaf collimator

A multi-leaf collimator and control method technology, applied in the field of medical electronics, can solve the problems of hazards, increase the leakage of rays from the end faces of incompletely closed leaves, and achieve the effect of preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below figure 1 to attach Figure 5 The present invention will be further described.

[0024] The multi-leaf collimator blade anti-collision control method comprises the following steps:

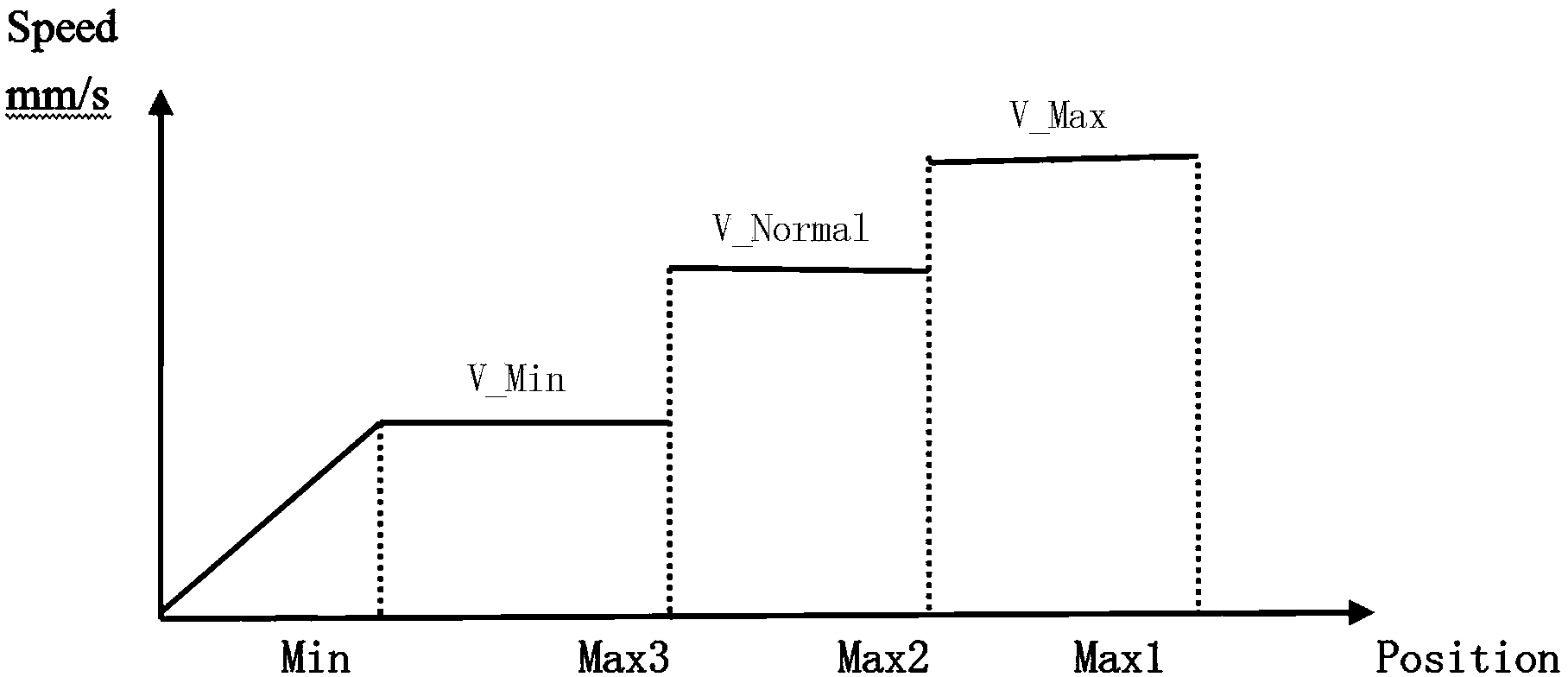

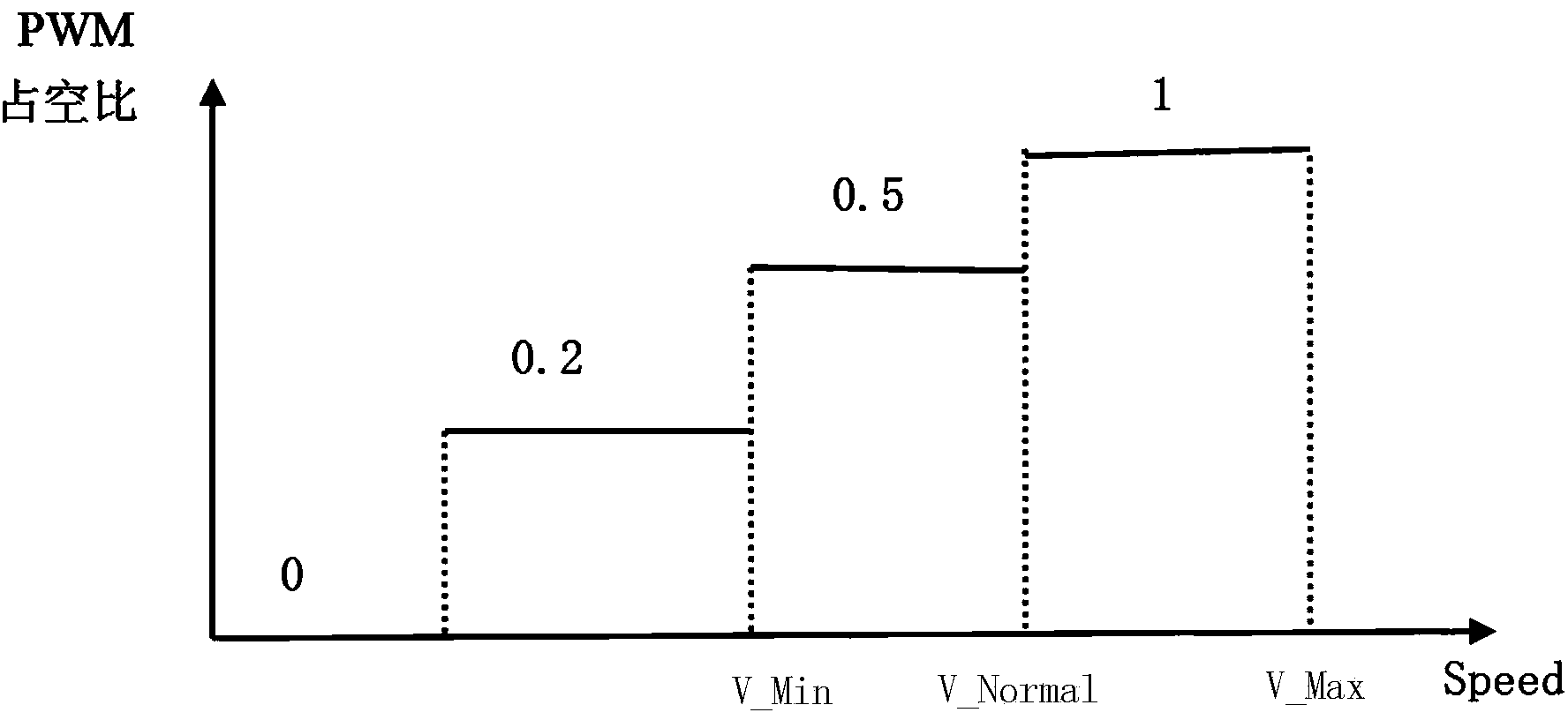

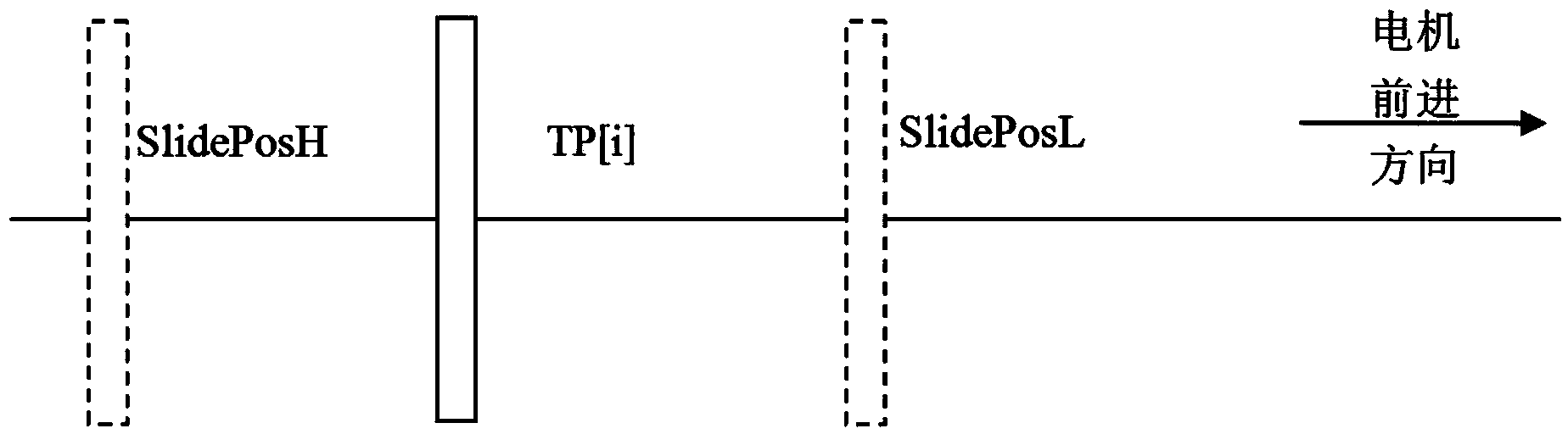

[0025] (1) At present, for the non-switching multi-leaf collimator, the movement of the blades is completed by the motor driving the lead screw, and the rotation motion of the motor is converted into the linear motion of the blades through the lead screw. The movement speed of the motor is carried out by means of pulse width modulation (PWM). Therefore, for the convenience of calculation, the moving distance of the blade can be converted into the number of encoder pulses. The minimum distance between the two groups of leaves of the multi-leaf collimator A and B is set to 0.1mm when they are closed, according to the formula Calculate the positioning error e of blades A and B, where N is the number of pulses sent by the encoder when the blade runs 1mm. Assuming that 1mm co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com