Combined metal solid armature for electromagnetic emission and manufacturing method thereof

A combined, solid technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of solid armature skin effect and anti-ablation to be improved, and achieve the effect of improving the anti-ablation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

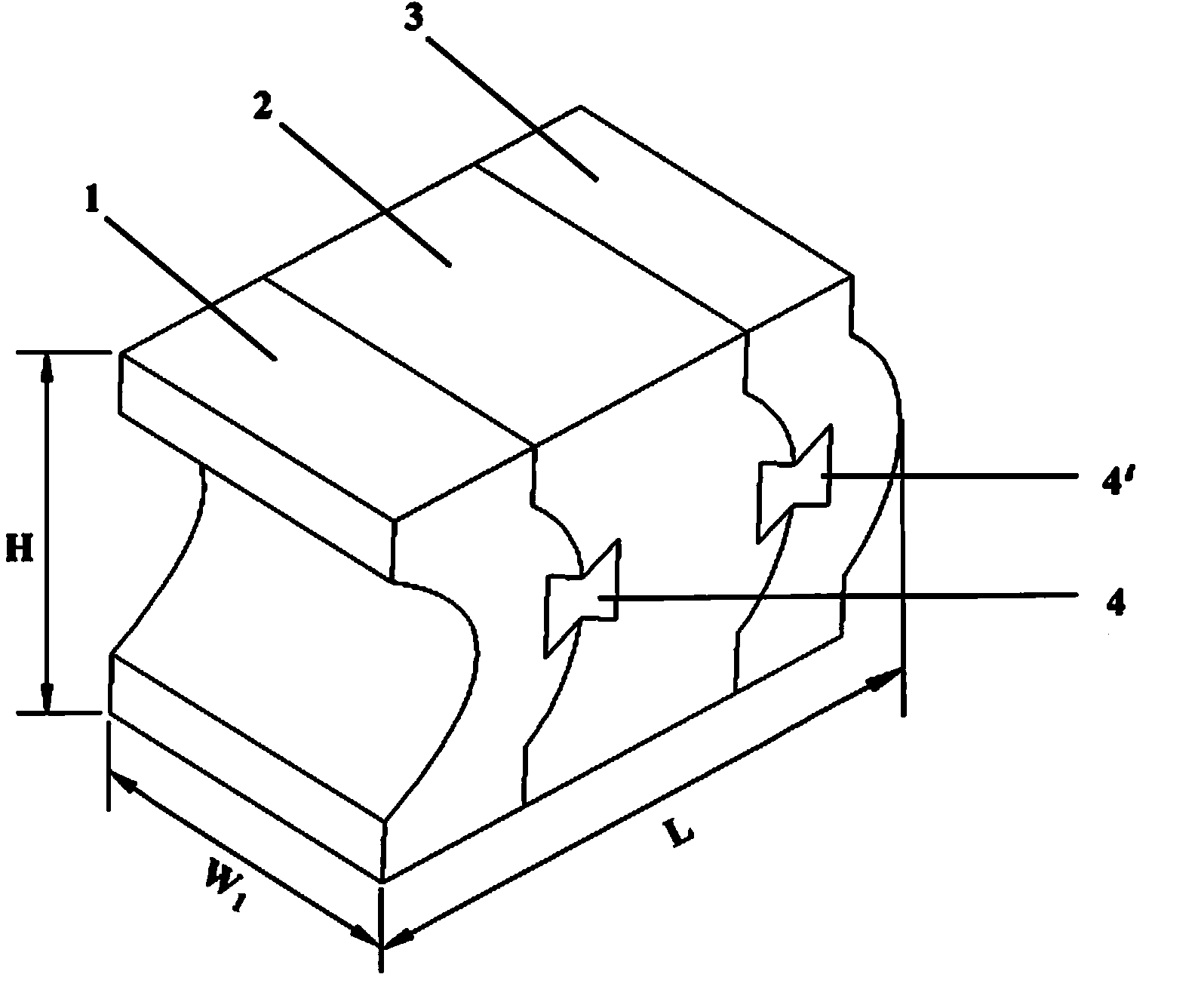

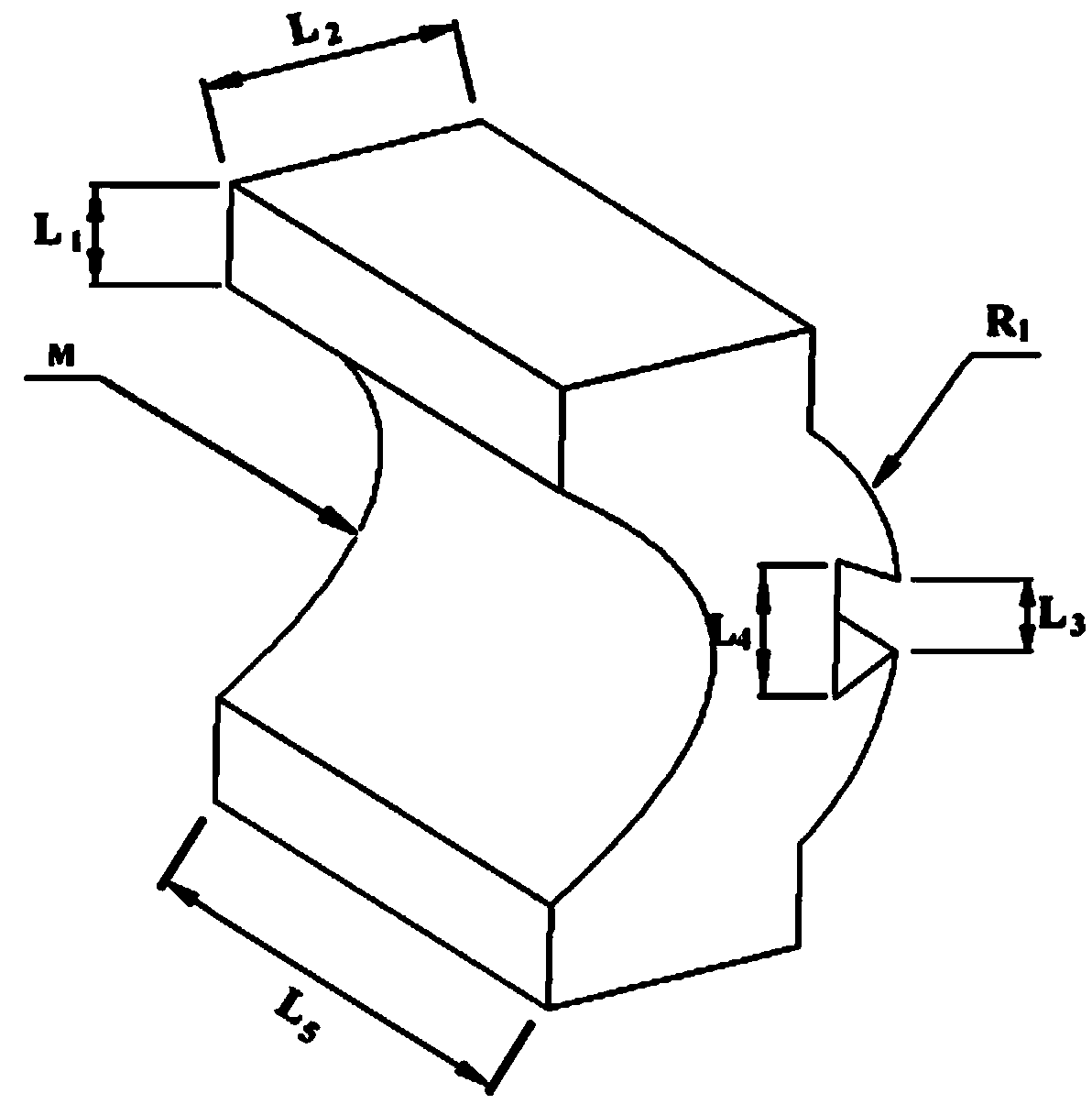

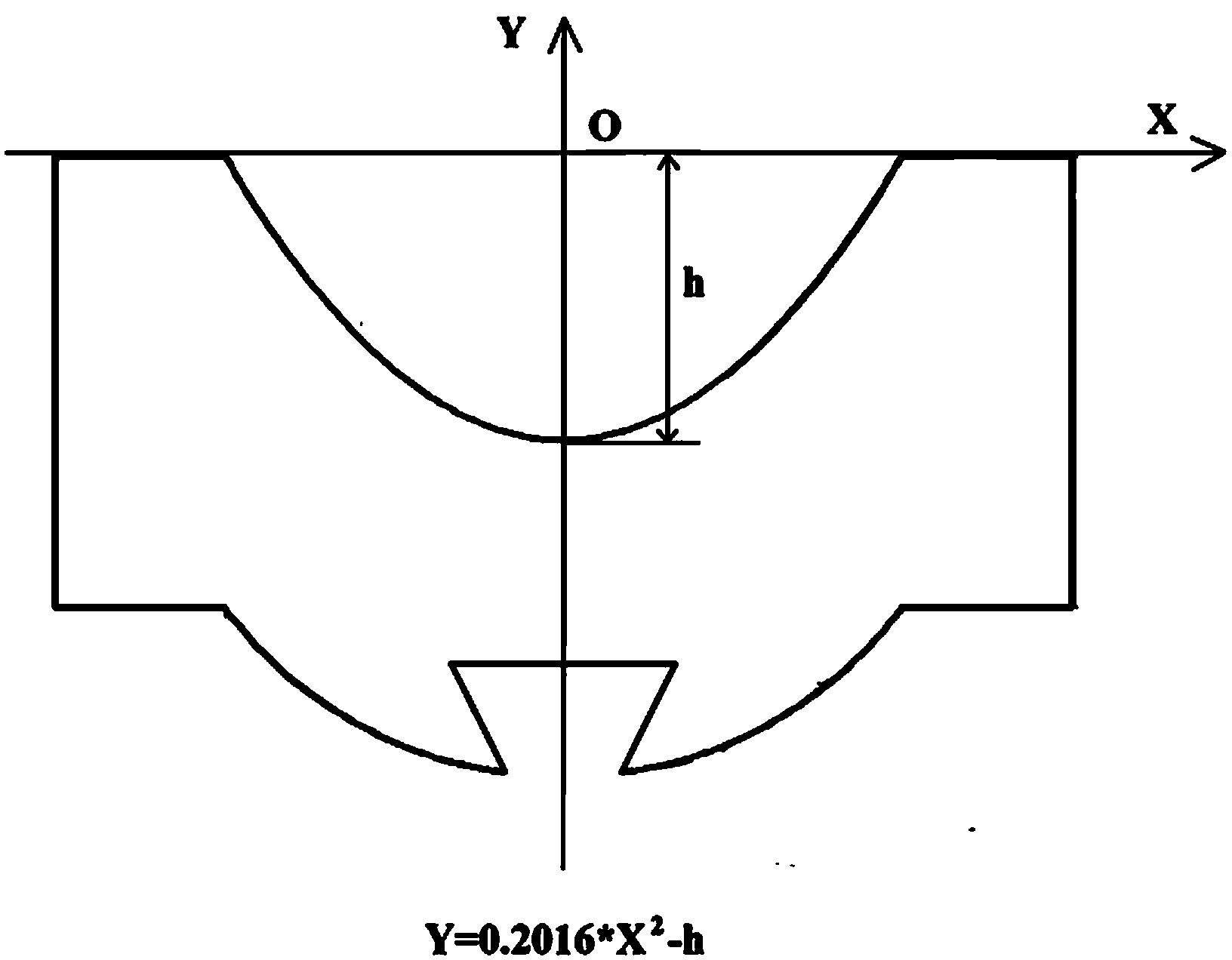

[0050] figure 1 It is the first embodiment disclosed by the present invention, aiming at a kind of electromagnetic launch track whose diameter is 16mm×18mm (width H×height W 1 ) device, the present invention provides a combination metal solid armature for electromagnetic emission. The size of the whole armature is 30 mm x 16 mm x 18 mm (length L x width H x height W 1 ). Among them, the ratio of the contact area between the pure copper block 3, the pure aluminum block 2 and the industrial pure titanium (brand is TA1) block 1 and the electromagnetic emission track is 1:2:1.3. Thickness L of the rear end of block 1 of industrially pure titanium (grade TA1) 1 is 3mm, and the back end processes a parabolic surface M, and the parabolic equation is Y=0.2016X 2 -5.04, the front end arc radius R of titanium block 1 1 is 7.5mm, and the center of the circle is on the axis of symmetry; the length L of block 1 of industrial pure titanium (grade TA1) 2 is 8 mm; the size of the front ...

Embodiment 2

[0053] For an electromagnetic launch track with a diameter of 21 mm x 24 mm (width H x height W 1 ) device, the present invention provides a combination metal solid armature for electromagnetic emission. The size of the whole armature is 40 mm x 21 mm x 24 mm (length L x width H x height W 1 ). Among them, the ratio of the contact area between the pure copper block 3, the pure aluminum block 2 and the industrial pure titanium (brand is TA1) block 1 and the electromagnetic emission track is 1:2:1.3. Thickness L of the rear end of block 1 of industrially pure titanium (grade TA1) 1 It is 4mm, and the rear end processes the parabolic surface M, and the parabolic equation is Y=0.2016X 2 -5.04, front end arc radius R 1 is 10 mm, and the center of the circle is on the axis of symmetry; the length L of block 1 of industrial pure titanium (brand name TA1) 2 is 10.7 mm; the size of the front dovetail groove is: top width L 3 3 mm, bottom width L 4 6 mm (see figure 2 , 3 ). T...

Embodiment 3

[0056] For an electromagnetic launch track with a diameter of 19.2 mm x 21.6 mm (width H x height W 1 ) device, the present invention provides a combination metal solid armature for electromagnetic emission. The size of the whole armature is 36 mm x 19.2 mm x 21.6 mm (length L x width H x height W 1 ). Among them, the ratio of the contact area between the pure copper block 3, the pure aluminum block 2 and the industrial pure titanium (brand is TA1) block 1 and the electromagnetic emission track is 1:2:1.3. Thickness L of the rear end of block 1 of industrially pure titanium (grade TA1) 1 It is 3.6 mm, and the rear end processes a parabolic surface M, and the parabolic equation is Y=0.2016X 2 -5.04, radius R of front end arc of block 1 of industrially pure titanium (grade TA1) 1 is 9 mm, and the center of the circle is on the axis of symmetry; the length L of block 1 of industrial pure titanium (grade TA1) 2 is 9.6 mm; the size of the front dovetail groove is: top width L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com