Thin film type semi-rigid solar cell array and manufacturing method thereof

A technology for solar cell arrays and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of heavy semi-rigid solar cell arrays, complicated manufacturing processes, and low production efficiency of semi-rigid solar cell arrays. Lightweight, fewer connection points, less risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

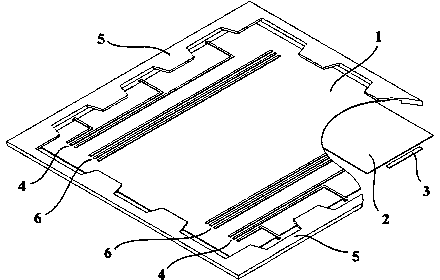

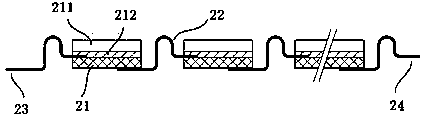

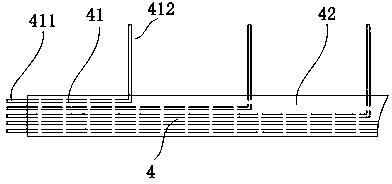

[0046] Such as figure 1 As shown, the thin-film semi-rigid solar cell array includes a substrate 1, a solar cell module 2 laid on one surface of the substrate 1, a connecting piece 3 arranged on the same surface of the substrate 1, and an inner plate arranged on the other surface of the substrate 1. cable 4. In this embodiment, the substrate 1 is made of lightweight film material or sheet material, such as glass fiber, carbon fiber, polyimide, etc., to reduce the weight of the cell array. The connection piece 3 , the intra-board cable 4 and the inter-board cable 6 are all thin metal sheets with a specific shape laid on the substrate. The connecting piece 3, the intra-board cable 4 and the inter-board cable 6 are made of metal materials that are easy to weld, have low resistance, soft quality and good toughness, preferably silver, copper or valveable alloy. The frame 5 is made of lightweight rigid material, such as aluminum alloy and carbon fiber composite material. Laying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com