A method for preparing graphene composite ternary material by monoalcohol solvothermal method

A graphene composite, ternary material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low initial charge and discharge efficiency, inability to exert rate performance, poor structural stability, etc., and achieve electrochemical performance. Excellent, low toxicity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

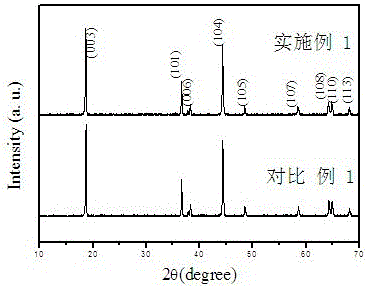

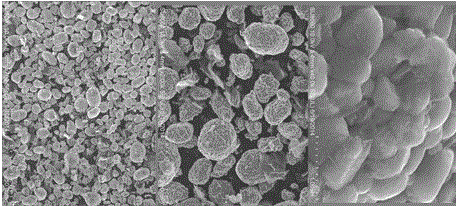

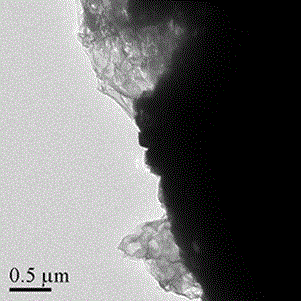

Embodiment 1

[0032] Commodity ternary material LiNi 0.5 co 0.3 mn 0.2 o 2 (Type 523), pre-treatment of commodity graphene: LiNi 0.5 co 0.3 mn 0.2 o 2 , graphene was dried in an oven at 120 °C for 3 h, and after cooling, it was ground separately until no agglomeration occurred, and then put into a desiccator for use; 0.1000 g of the above graphene was accurately weighed with a balance, and dispersed in a container Put magnets into a reaction kettle with 50 ml of anhydrous isopropanol, and use ultrasonic waves to assist dispersion; use a balance to accurately weigh 10.0021 g of ternary materials, graphene and LiNi 0.5 co 0.3 mn 0.2 o 2 The mass percentage is 1:100, and it is added to the inner lining of the reaction kettle in 3 times, stirred for 30 min, the magnet is taken out, the reaction kettle is closed, and it is put into an oven at 180 °C. After reacting for 12 hours, it is naturally cooled, and then Take out the lining of the reaction kettle for suction filtration, wash wit...

Embodiment 2

[0036] Commodity ternary material LiNi 0.5 co 0.3 mn 0.2 o 2 (type 523), graphene is pre-treated: the LiNi 0.5 co 0.3 mn 0.2 o 2 1. Graphene was dried in an oven at 150 °C for 2 hours, and after cooling, it was ground separately until no agglomeration occurred, and then put into a desiccator for use; 0.1001 g of graphene was accurately weighed with a balance, and dispersed in a container containing 50 Put a magnet in the reaction kettle in ml of absolute ethanol, and disperse with the help of ultrasonic waves; use a balance to accurately weigh 10.0002 gLiNi 0.5 co 0.3 mn 0.2 o 2 , graphene and LiNi 0.5 co 0.3 mn 0.2 o 2 The mass percentage is 1:100, and it is added to the lining of the reactor in 4 times, stirred for 30 min, the magnet is taken out, the reactor is closed, and it is placed in an oven with a temperature of 180 °C. After 12 hours of reaction, it is cooled naturally. Take out the inner liner for suction filtration, wash with ethanol three times, and ...

Embodiment 3

[0039] Commodity ternary material LiNi 0.5 co 0.3 mn 0.2 o 2 (type 523), graphene is pre-treated: the LiNi 0.5 co 0.3 mn 0.2 o 2 1. Graphene was dried in an oven at 180°C for 2 hours, and after cooling, it was ground separately until no agglomeration occurred, and then put into a desiccator for subsequent use; 0.0999 g of graphene was accurately weighed with a balance, and dispersed in a container containing 50 ml of anhydrous isopropanol reaction kettle, put magnets, use ultrasonic wave to assist dispersion; use balance to accurately weigh 9.9992 gLiNi 0.5 co 0.3 mn 0.2 o 2 , graphene and LiNi 0.5 co 0.3 mn 0.2 o 2 The mass percentage is 1:100, and it is added to the lining of the reactor in 4 times, stirred for 30 min, the magnet is taken out, the reactor is closed, and it is placed in an oven with a temperature of 200 ° C. After 24 hours of reaction, it is cooled naturally. Take out the inner liner for suction filtration, wash three times with isopropanol, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com