Method for manufacturing multiple solder mask layers on PCB

A technology of solder mask and solder mask ink, which is applied in the manufacture of multi-layer circuits, application of non-metallic protective layers, secondary processing of printed circuits, etc. Low problems, to avoid scratches or pollution, easy operation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

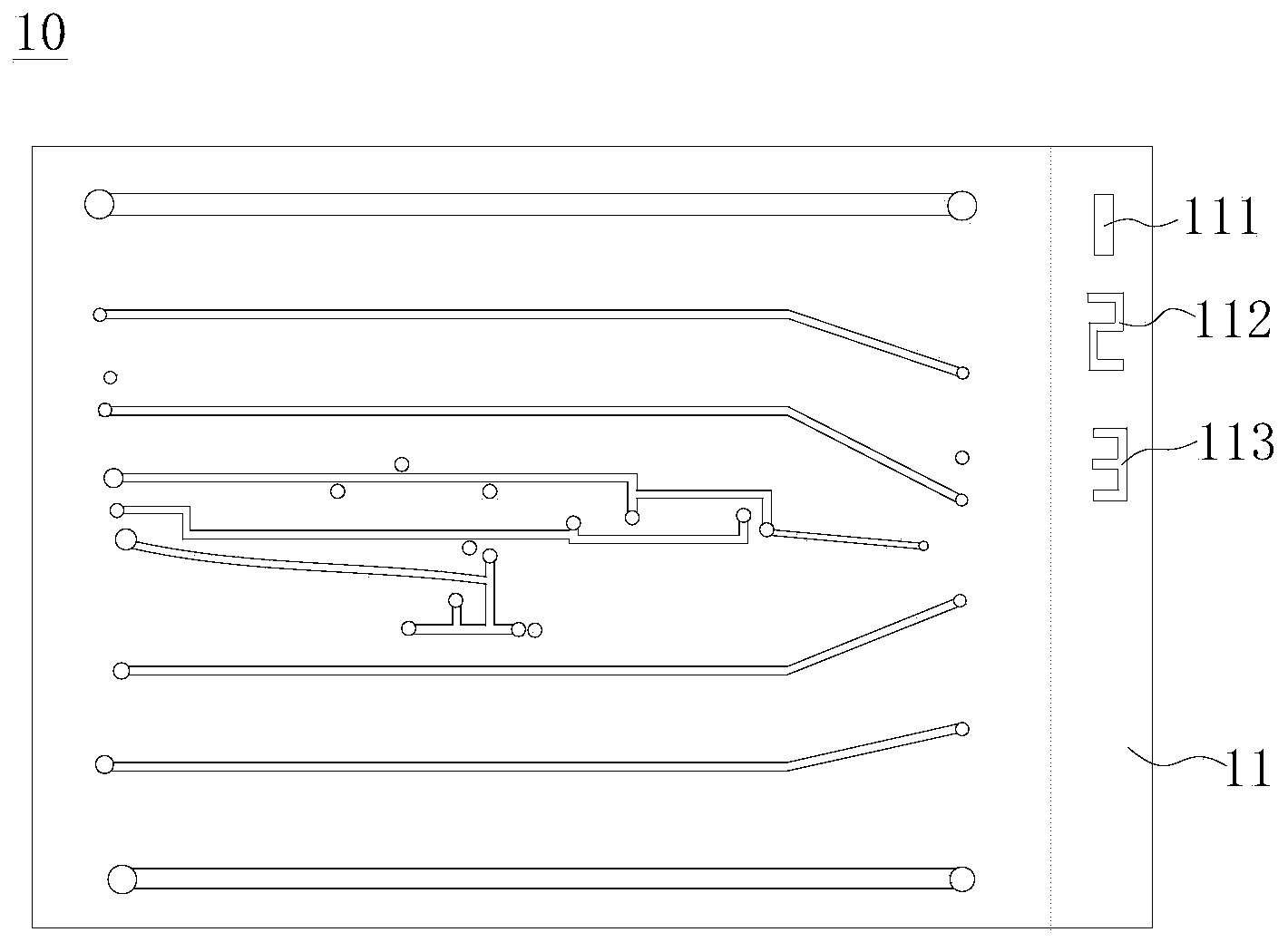

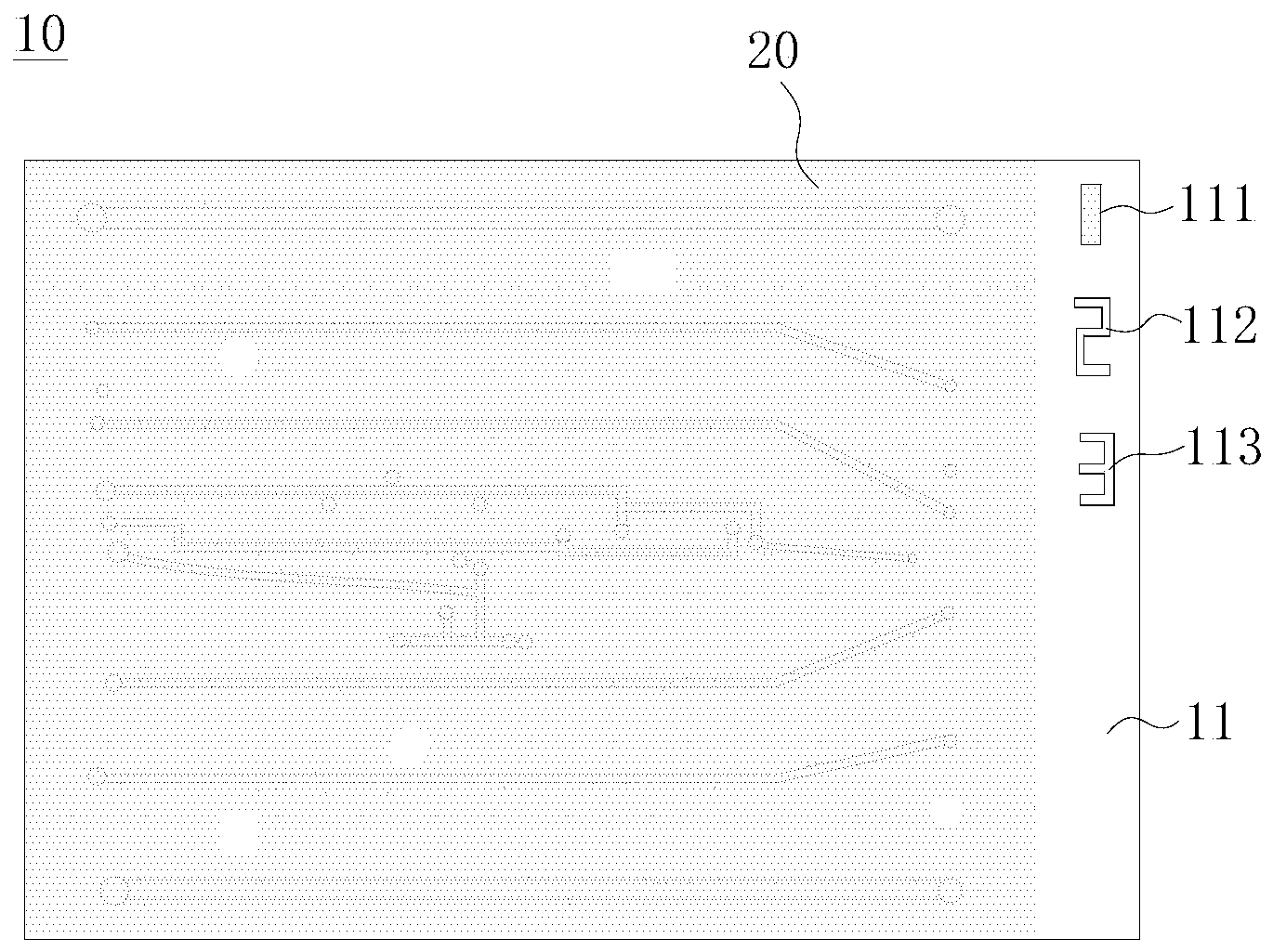

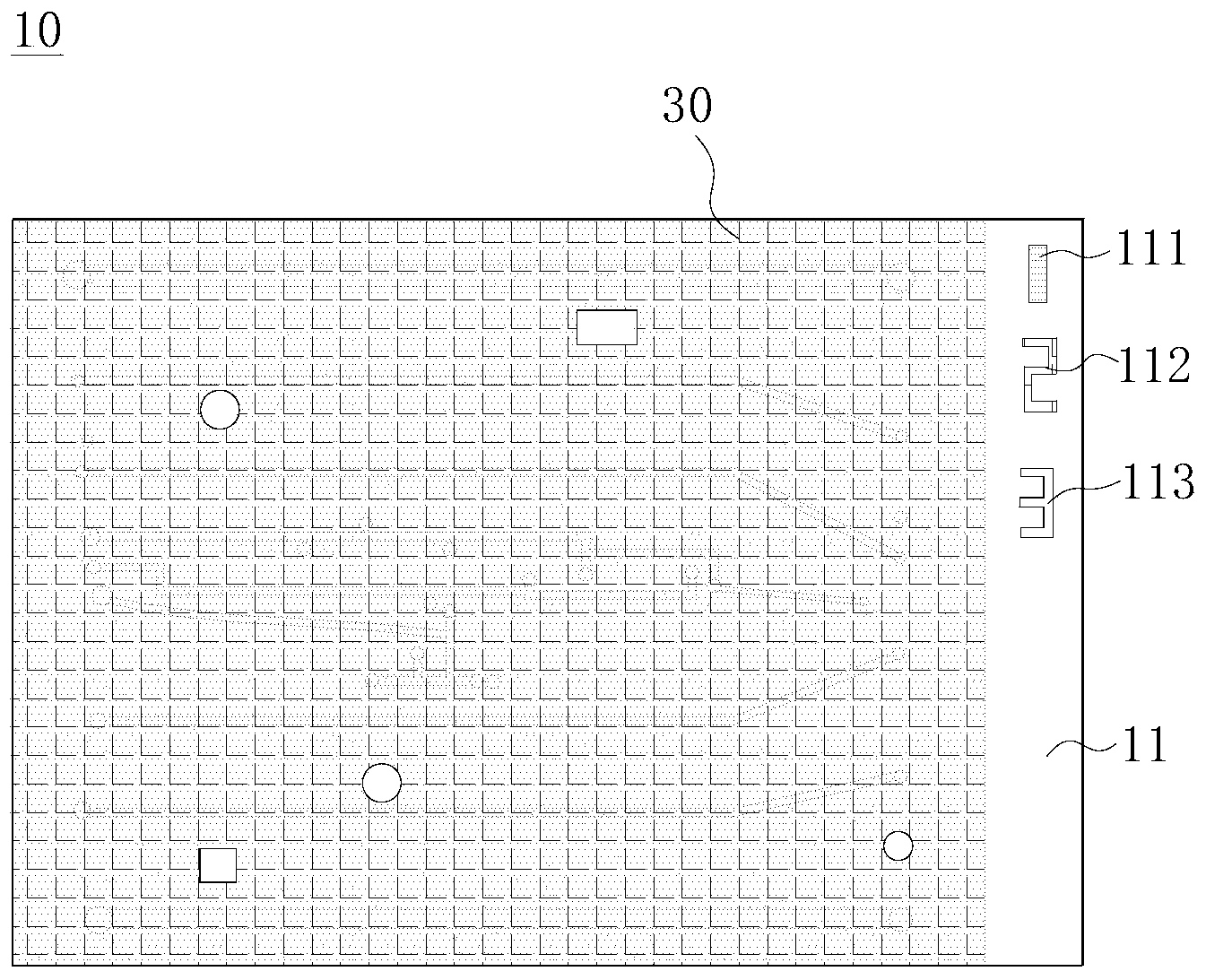

[0019] refer to Figure 1-4 , a kind of method for making three-layer solder resist layer on PCB provided by this embodiment, comprises the following steps:

[0020] (1) As in the circuit board production process of the prior art, the raw materials of each layer of circuit board are cut, and then the inner layer pattern transfer and pattern electroplating are carried out on each inner layer circuit board to form the inner layer circuit, and then each layer of circuit board is Lamination is carried out to form a multi-layer laminated board, and then holes are drilled on the multi-layer laminated board. After drilling, the multi-layer laminated board is subjected to copper sinking and full board electroplating. Then, make the outer layer graphics on the multilayer laminated board, and when making the outer layer graphics, design the logo (Arabic numerals) 111 for marking the three-layer solder resist layer that needs to be made later on the process side of the multilayer laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com