Preparation method for double-supported columbate material

A technology of niobate and photocatalytic materials, applied in chemical instruments and methods, catalyst supports, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

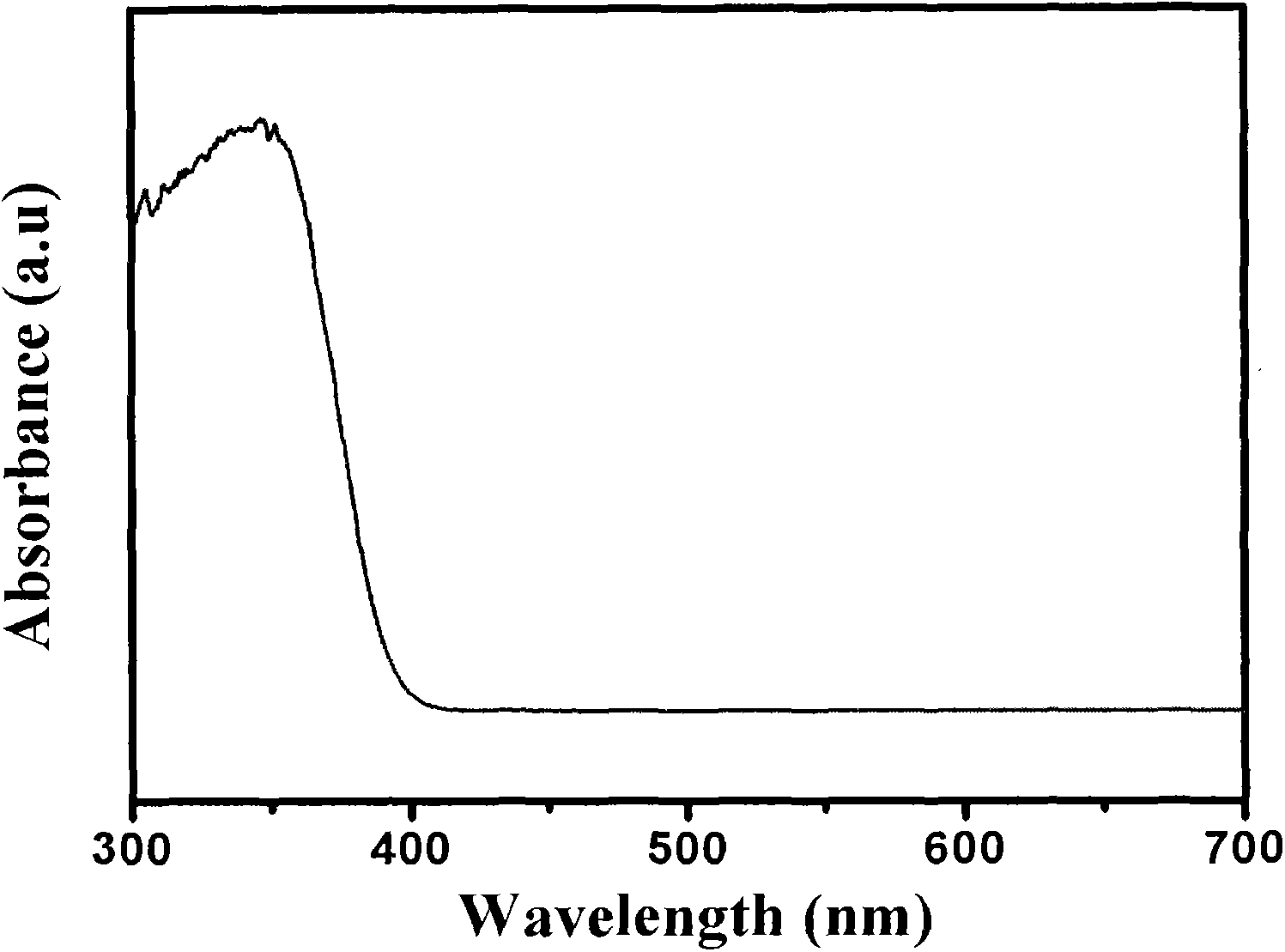

Image

Examples

specific Embodiment approach 1

[0008] (1) Nb 2 o 5 , Na 2 CO 3 , K 2 CO 3 According to KNbO 3 Stoichiometric mixing.

[0009] (2) After grinding the mixture, preheat it at 800° C. for 4 hours.

[0010] (3) After grinding again, calcining at a temperature of 900°C for 5h to obtain KNbO 3 .

[0011] (4) 1g KNbO 3 Add to a glass container, add 100mL of distilled water, 40mL of methanol and a certain amount of chloroplatinic acid.

[0012] (5) The prepared solution was magnetically stirred to form a suspension solution, and a 300W xenon lamp was irradiated for 8 hours to reduce the Pt and deposit it on the surface of the photocatalyst.

[0013] (6) After the reaction, the reaction solution was filtered and washed with water and alcohol several times.

[0014] (7) Put it into a blast drying oven at 60° C. for 8 hours to form a Pt-loaded photocatalytic material.

specific Embodiment approach 2

[0015] (1) Nb 2 o 5 , Na 2 CO 3 , K 2 CO 3 According to KNbO 3 Stoichiometric mixing.

[0016] (2) After grinding the mixture, preheat it at 800° C. for 4 hours.

[0017] (3) After regrinding, calcining at 900°C for 5h to obtain KNbO 3 .

[0018] (4) 2g KNbO 3 and an appropriate amount of Ru 3 (CO) 12 The tetrahydrofuran solution was placed in a ceramic evaporating dish.

[0019] (5) Stir magnetically at room temperature for 4 hours and then dry in an oven (60° C.).

[0020] (6) After drying, bake at 350°C for 1 hour to form RuO 2 supported photocatalytic materials.

specific Embodiment approach 3

[0021] (1) Nb 2 o 5 , Na 2 CO 3 , K 2 CO 3 According to KNbO 3 Stoichiometric mixing.

[0022] (2) After grinding the mixture, preheat it at 800° C. for 4 hours.

[0023] (3) After regrinding, calcining at 900°C for 5h to obtain KNbO 3 .

[0024] (4) 2g KNbO 3 and an appropriate amount of Ru 3 (CO) 12 The tetrahydrofuran solution was placed in a ceramic evaporating dish.

[0025] (5) Stir magnetically at room temperature for 4 hours and then dry in an oven (60° C.).

[0026] (6) After drying, bake at 350°C for 1 hour to form RuO 2 supported photocatalytic materials.

[0027] (7) 1g KNbO 3 Join the formed RuO 2 Add 100 mL of distilled water, 40 mL of methanol and a certain amount of chloroplatinic acid to the loaded photocatalytic material.

[0028] (8) The prepared solution was magnetically stirred to form a suspension solution, and a 300W xenon lamp was irradiated for 8 hours to reduce the Pt and deposit it on the surface of the photocatalyst.

[0029] (9) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com