polyimide film

A technology of polyimide film and gel film, which is applied in the direction of film/sheet adhesives, chemical instruments and methods, layered products, etc., which can solve the problem of not taking into account the strain of the film, and the inability of components and substrates to be well bonded Insufficient improvement of connection and dimensional change in the diagonal direction of flexible metal laminates, etc., to achieve small dimensional change rate, stable dimensional change rate, and improved positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Hereinafter, the present invention will be described in more detail by citing examples, but the present invention is not limited by these examples, and many modifications made within the technical idea of the present invention can also be utilized by those skilled in the art.

[0106] Hereinafter, methods for measuring various characteristics of the present invention will be described.

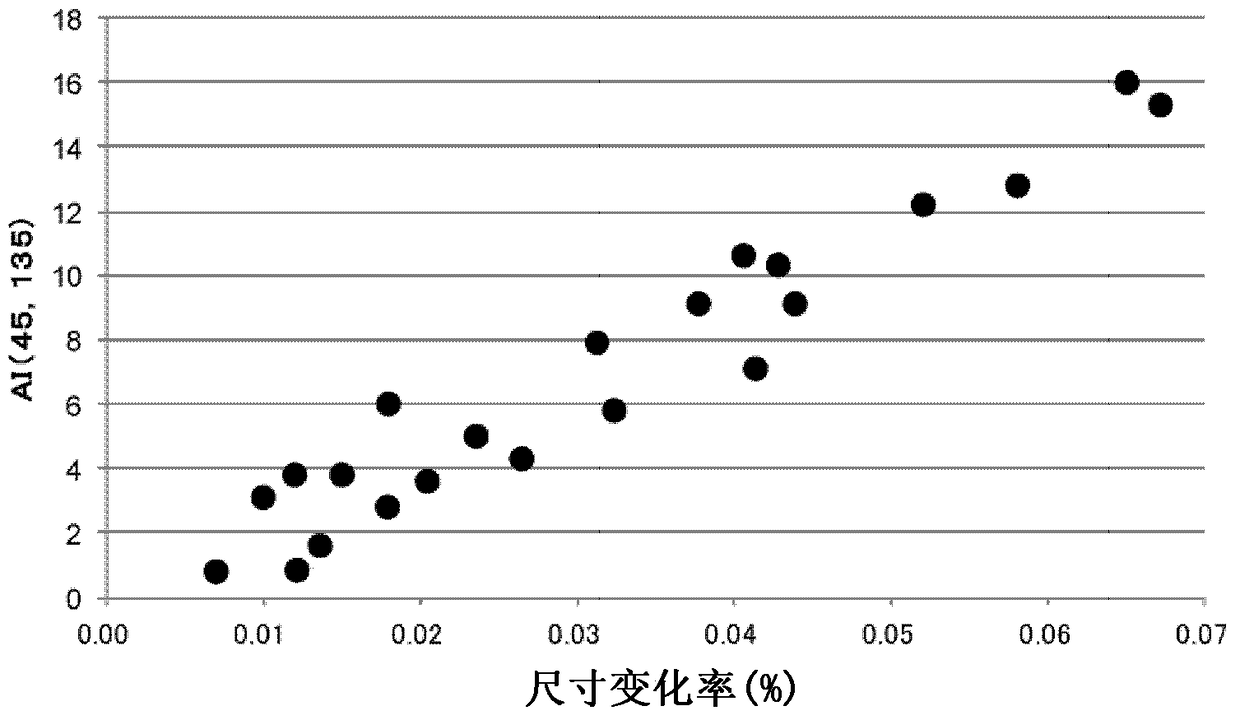

[0107] (1) AI (45, 135)

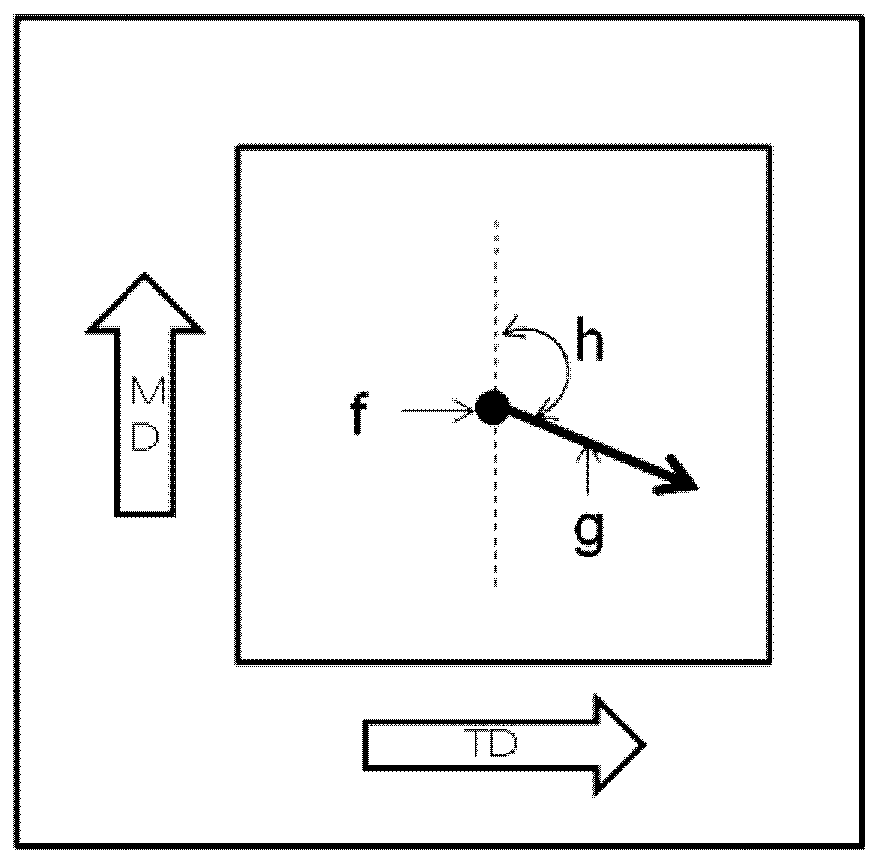

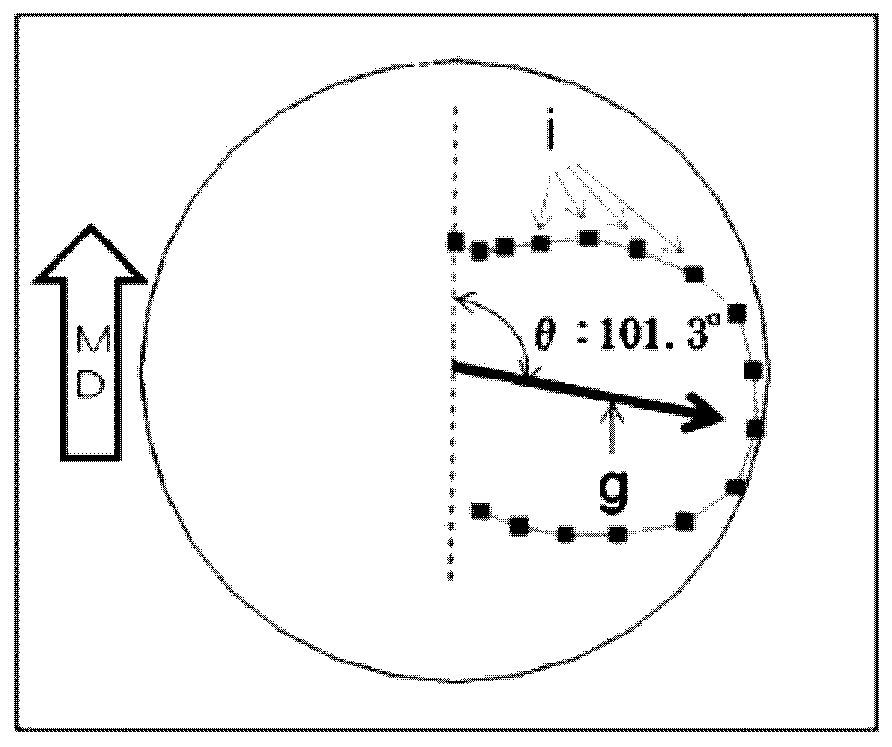

[0108]The propagation velocity V of the ultrasonic pulse in the present invention was measured using SST-2500 (Sonic Sheet Tester) manufactured by Nomura Corporation. Using SST-2500, ultrasonic velocities in 16 directions every 11.25° in the surface direction of the film from 0 to 180° (0° is parallel to the MD direction) were automatically measured. Among the obtained velocities in each direction, the anisotropy index (AI) shown in Formula 1 was obtained from ultrasonic velocities V45 and V135 at 45° and 135° based on the MD direction. Using the films obta...

Synthetic example 2

[0119] Prepare pyromellitic dianhydride (molecular weight 218.12) / 3,3',4,4'-biphenyltetracarboxylic dianhydride (molecular weight 294.22) / 4 according to the molar ratio of 65 / 35 / 80 / 20, 4'-diaminodiphenyl ether (molecular weight 200.24) / p-phenylenediamine (molecular weight 108.14), in DMAc (N,N-dimethylacetamide), make 20% by weight solution and polymerize to obtain 3500 poise poly Amic acid solution.

Synthetic example A

[0121] Add 1,3-bis(4-aminophenoxy)benzene into the solvent dimethylacetamide and stir until it dissolves. Thereafter, 4,4'-dioxydiphthalic anhydride was added and stirred to obtain a polyamic acid solution. The solid content in dimethylacetamide was 15%, and Tg was 217°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com