Polyether polyol system for external wall spraying and preparation method

A combination of polyether and low-density technology, applied in the field of polyurethane foam, can solve the problems of unsatisfactory application, high production cost, and large change in dimensional stability, and achieve high labor production efficiency, flexible and convenient construction, and high dimensional change rate small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

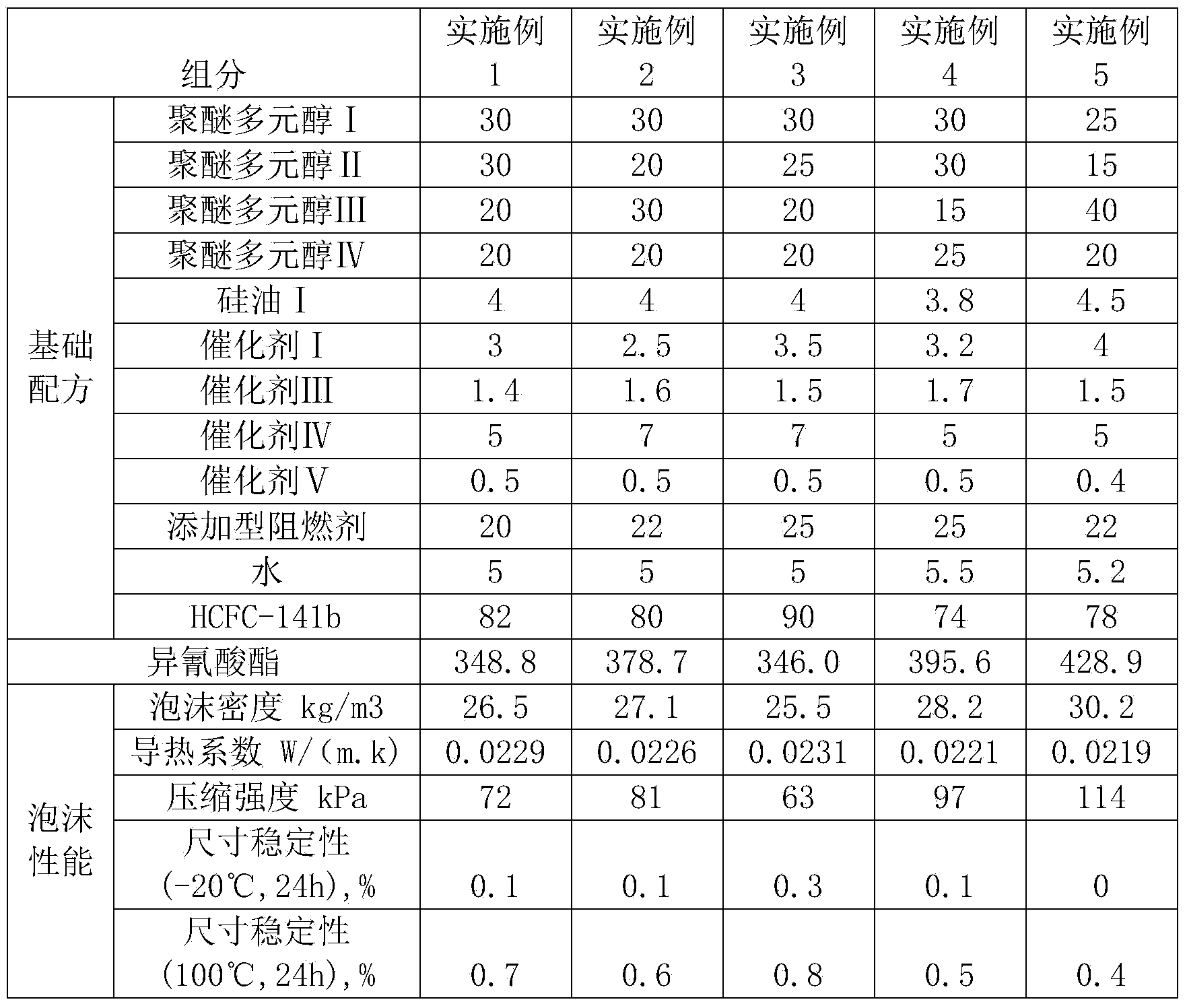

Examples

Embodiment Construction

[0032] A low-density exterior wall spraying assembly polymer, which consists of the following parts by weight:

[0033] Polyether polyol Ⅰ is 10-40 parts,

[0034] Polyether polyol II is 0-50 parts,

[0035] Polyether polyol Ⅲ is 0-50 parts,

[0036] 15-30 parts of polyether polyol IV,

[0037] Catalyst I is 0.6-4 parts,

[0038] Catalyst III is 0~2 parts,

[0039] Catalyst IV is 0-10 parts,

[0040] Catalyst V is 0 to 1 part,

[0041] Silicone oil I is 0-5 parts,

[0042] Additive flame retardant is 10~35 parts,

[0043] 2.6-10 parts of water,

[0044] The blowing agent HCFC-141b is 36-150 parts,

[0045] Said polyether polyol I uses ethylene diamine as an initiator, propylene oxide and ethylene oxide are polymerized, and has a functionality of 4 and a hydroxyl value of 700-900 mgKOH / g; polyether polyol II uses sucrose, two Glycol is the starter, propylene oxide is polymerized, and its functionality is 6, and the hydroxyl value is 300-450mgKOH / g; polyether polyol Ⅲ uses sorbitol as the initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com