Preparation method of novel hard foam polyether polyol

A technology of polyether polyol and hard foam, which is applied in the field of polyether polyol synthesis, can solve problems such as hazardous operation, inconvenient, and harmful to human health, and achieve the effects of reduced dosage, sufficient reaction, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

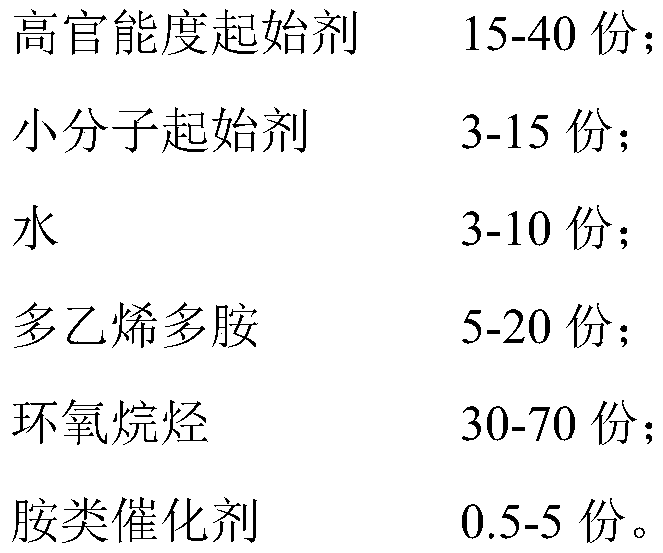

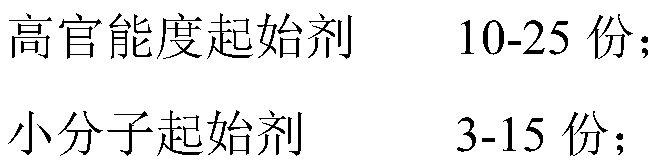

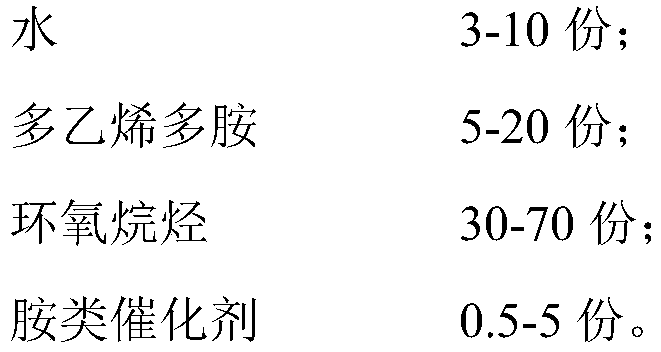

Method used

Image

Examples

Embodiment 1

[0029] Add 480g of sucrose, 120g of diethylene glycol, 100g of water, 10g of dimethylamine and 130g of triethylenetetramine into a 5L polymerization reactor, and then punch and test the polymerization reactor to ensure good sealing, and perform nitrogen replacement 5 times , then evacuate to the minimum vacuum degree of -0.093MPa, set the temperature to 85°C and raise the temperature, start to add propylene oxide dropwise at 80°C, maintain the temperature at 80°C, until the amount of propylene oxide added is 146g, Stop feeding propylene oxide, and start aging for 2 hours at a temperature of 90°C, maintaining a pressure of 0.15 MPa. After curing, keep the vacuum pressure less than -0.088MPa until the sampling test result is 0.3%. Then add 15g of dimethylamine, stir evenly, raise the temperature to 110°C, start to add 805g of propylene oxide dropwise until the feeding is completed, maintain the pressure at 0.15MPa and mature for 2h, then add 10g of ethylenediamine and stir evenl...

Embodiment 2

[0031] 370g of solid sorbitol, 180g of glycerin, 90g of water, 13g of dimethylamine and 140g of tetraethylenepentamine were added to a 5L polymerization reactor, and then the polymerization reactor was stamped and tested to ensure good sealing, and nitrogen replacement was performed 5 times. Then evacuate to the minimum vacuum degree -0.093MPa, set the temperature to 85°C and heat up, start to add propylene oxide dropwise at 80°C, keep the temperature at 80°C, stop when the amount of propylene oxide added is 224g Add propylene oxide, and start aging for 2 hours at a temperature of 90°C and maintain a pressure of 0.15MPa. After curing, keep the vacuum pressure less than -0.088MPa until the sampling test result is 0.3%. Then add 17g of dimethylamine and stir evenly, raise the temperature to 110°C, start to drop 747g of propylene oxide until the end of feeding, maintain the pressure of 0.15MPa and mature for 2h, then add 10g of ethylenediamine and stir evenly, start to dropwise a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com