linear compressor

A technology of linear compressors and linear motors, applied in mechanical equipment, electromechanical devices, and control of mechanical energy, can solve the problems of rising and insufficient manufacturing costs of linear compressors, reduce manufacturing costs, reduce cogging forces, and prevent The effect of external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. However, the idea of the present invention is not limited to the proposed embodiments, and those skilled in the art who understand the idea of the present invention can easily propose other embodiments within the scope of the same idea.

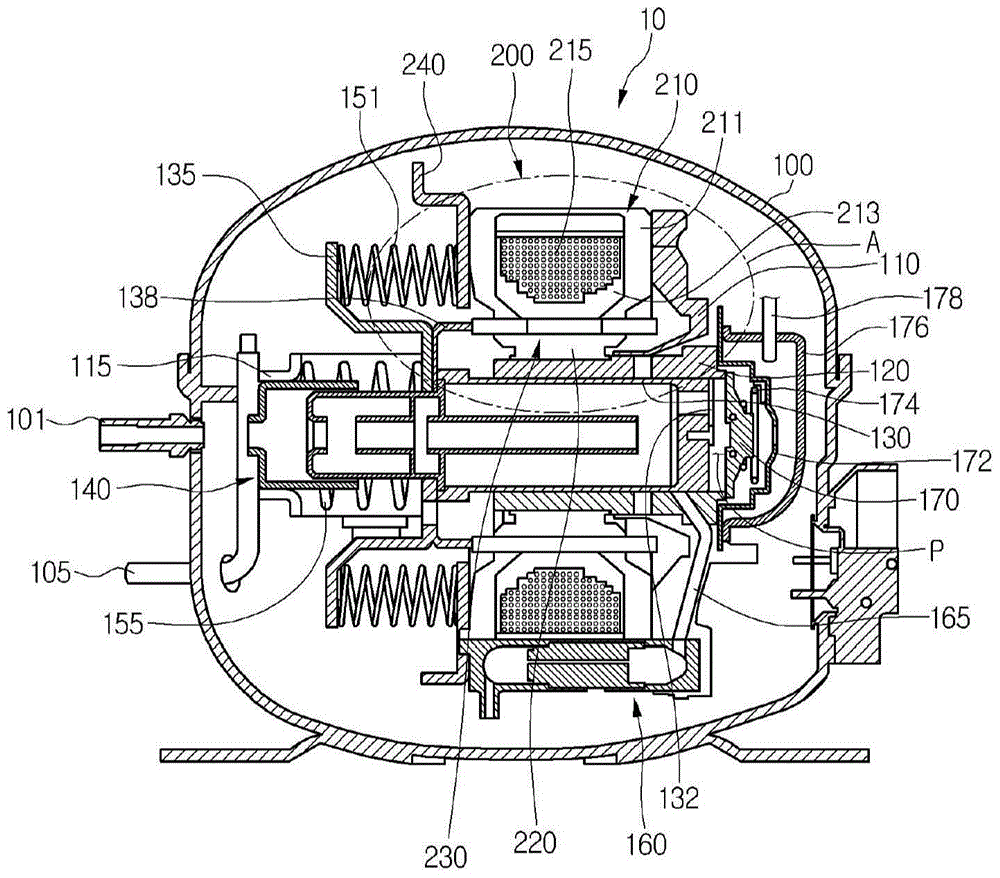

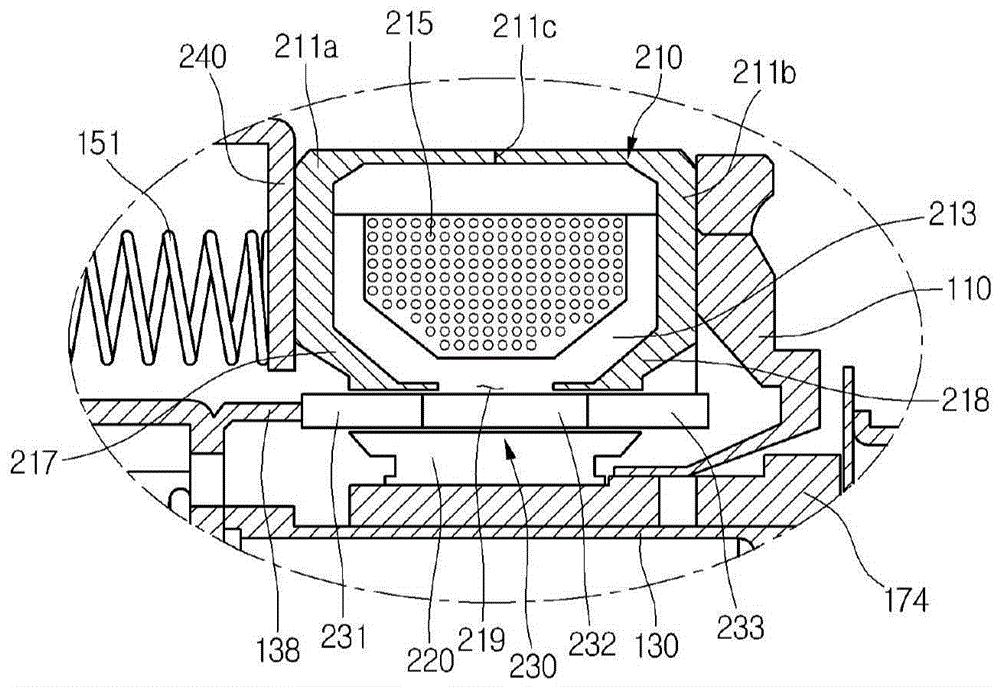

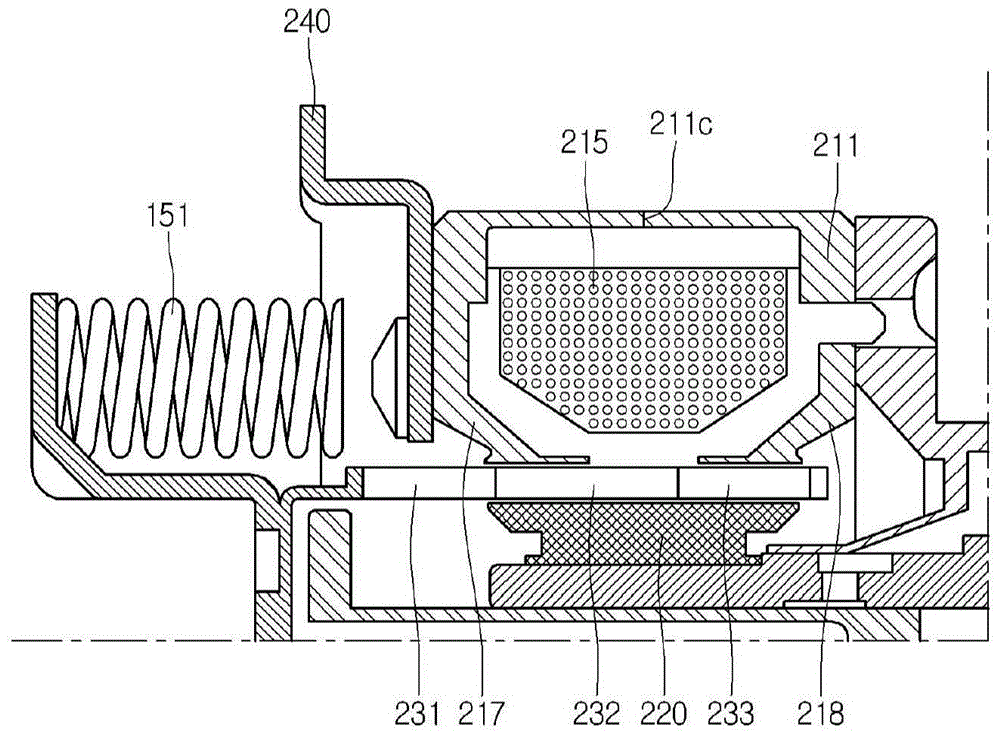

[0050] figure 1 It is a cross-sectional view showing the internal structure of the linear compressor according to the embodiment of the present invention.

[0051] Reference figure 1 , The linear compressor 10 of the embodiment of the present invention includes: a cylinder 120, which is provided inside the housing 100; a piston 130, which reciprocates linearly inside the cylinder 120; and a motor assembly 200 as a drive to the piston 130 Powerful linear motor. The above-mentioned housing 100 may be formed by combining an upper housing and a lower housing.

[0052] The housing 100 includes a suction part 101 into which the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com