Manufacturing method of high-energy-density button lithium ion battery

A lithium-ion battery and high energy density technology, which is applied in secondary battery manufacturing, electrolyte storage battery manufacturing, battery electrodes, etc., can solve the problems of not being able to make full use of the button shell space and low energy density, and achieve short-circuit prevention and high energy density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

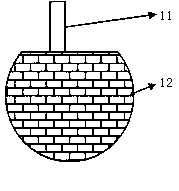

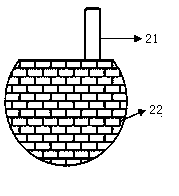

[0022] Step 1: Filming. Use a die to punch the positive and negative electrodes into small pieces, and the punched negative electrodes are as follows: figure 1 As shown, the negative electrode sheet is composed of two parts: the dressing part 12, the tab part 11; the punched positive electrode sheet is as figure 2 As shown, the positive electrode sheet is composed of two parts: the dressing part 22 and the tab part 21 .

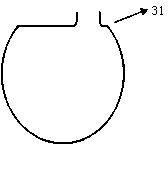

[0023] Step 2: Hot melt. The positive electrode sheet 42 is placed between the two layers of separators 41, the dressing part of the positive electrode sheet 42 is completely covered by the separator 41, and the ear part of the positive electrode sheet 42 (the part close to the dressing) is covered by the separator 41, most of which are on the outside of the diaphragm 41. Then use a hot-melt knife 31 that has the same shape as the dressing part of the positive electrode sheet and has a gap at the position of the corresponding positive electrode ear (the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com