A method for making yak qula suitable for pastoral areas

A production method and yak technology, applied in the field of production of yak koji, can solve the problems of slow drying speed, unstable product quality, oxidative browning of koji, etc., and achieve fast fermentation and drying speed, good color and flavor, Strong antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

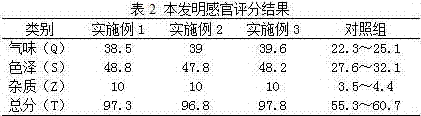

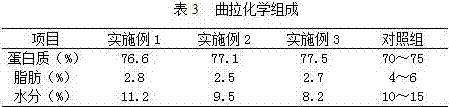

Embodiment 1

[0043] (1) Fresh milk collection: Collect 50 kg of fresh yak milk and filter it with 4 layers of gauze;

[0044] (2) Centrifugal degreasing: heat the filtered yak milk in a water bath to 45°C, use an electric cream separator to degrease at a speed of 5000r / min, and put the skim milk into a stainless steel bucket;

[0045] (3) Heat the skim milk water bath to 65°C, keep the temperature at a constant temperature for 30 minutes, and sterilize. Then put it in cold water and quickly cool it down to 41°C, pour it into a stainless steel insulation bucket, inoculate 75.0g of direct-throwing starter culture powder, stir evenly, seal it and keep it warm for fermentation. After 10.5 hours, the skim milk is completely solidified, and the precipitated whey is clear and transparent. fermentation;

[0046] (4) Pick up the coagulum obtained from the fermentation in step (3), put it into a stainless steel mesh tray with a 40-mesh filter cloth, cover and drain for 30 minutes, and there will be...

Embodiment 2

[0050] (1) Fresh milk collection: Collect 50 kg of fresh yak milk and filter it with 4 layers of gauze;

[0051] (2) Centrifugal degreasing: heat the filtered yak milk in a water bath to 50°C, use an electric cream separator at a speed of 4300r / min to degrease, and put the skim milk into a stainless steel bucket;

[0052] (3) Heat the skim milk water bath to 78°C and keep it warm for 18 minutes to sterilize. Sterilize. Then cool it in a water bath to 44°C, pour it into a stainless steel insulation bucket, inoculate 100.0g of direct-throwing starter, stir evenly, and seal the insulation bucket for fermentation. After 10 hours, the solids are completely solidified, and the precipitated whey is clear and transparent, and the fermentation is completed;

[0053] (4) Pick up the coagulum obtained from fermentation in step (3), put it into a stainless steel mesh tray with a 20-mesh filter cloth, cover and drain until no water drips;

[0054] (5) Disperse the drained coagulum into s...

Embodiment 3

[0057] (1) Fresh milk collection: Collect 50 kg of fresh yak milk and filter it with 4 layers of gauze;

[0058] (2) Centrifugal degreasing: heat the filtered yak milk in a water bath to 45°C, use an electric cream separator to degrease at a speed of 4600r / min, and put the skim milk into a stainless steel bucket;

[0059] (3) Heat the skim milk water bath to 90°C and keep it warm for 15 minutes to sterilize. Then put it in cold water and quickly cool it down to 45°C, pour it into a stainless steel insulation bucket, inoculate 150.0g of direct-throwing starter, stir evenly, and ferment in a sealed insulation bucket. After 7.5 hours, the solids are completely solidified, and the whey liquid is separated out, clear and transparent;

[0060] (4) Pick up the coagulum obtained from fermentation in step (3), put it into a stainless steel mesh tray with a 60-mesh filter cloth, cover it and drain until there is no water dripping;

[0061] (5) Disperse the drained coagulum into small p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com