Pressure type ACR (acrylate copolymer resin) emulsion polymerization reaction kettle

A technology of emulsion polymerization and reactor, which is applied in chemical/physical/physicochemical fixed reactors, pressure vessels/vacuum vessels, mixers, etc., can solve problems such as violent polymerization and reaction termination, and achieve economic benefits and reduce Heat energy loss, effect of increasing safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

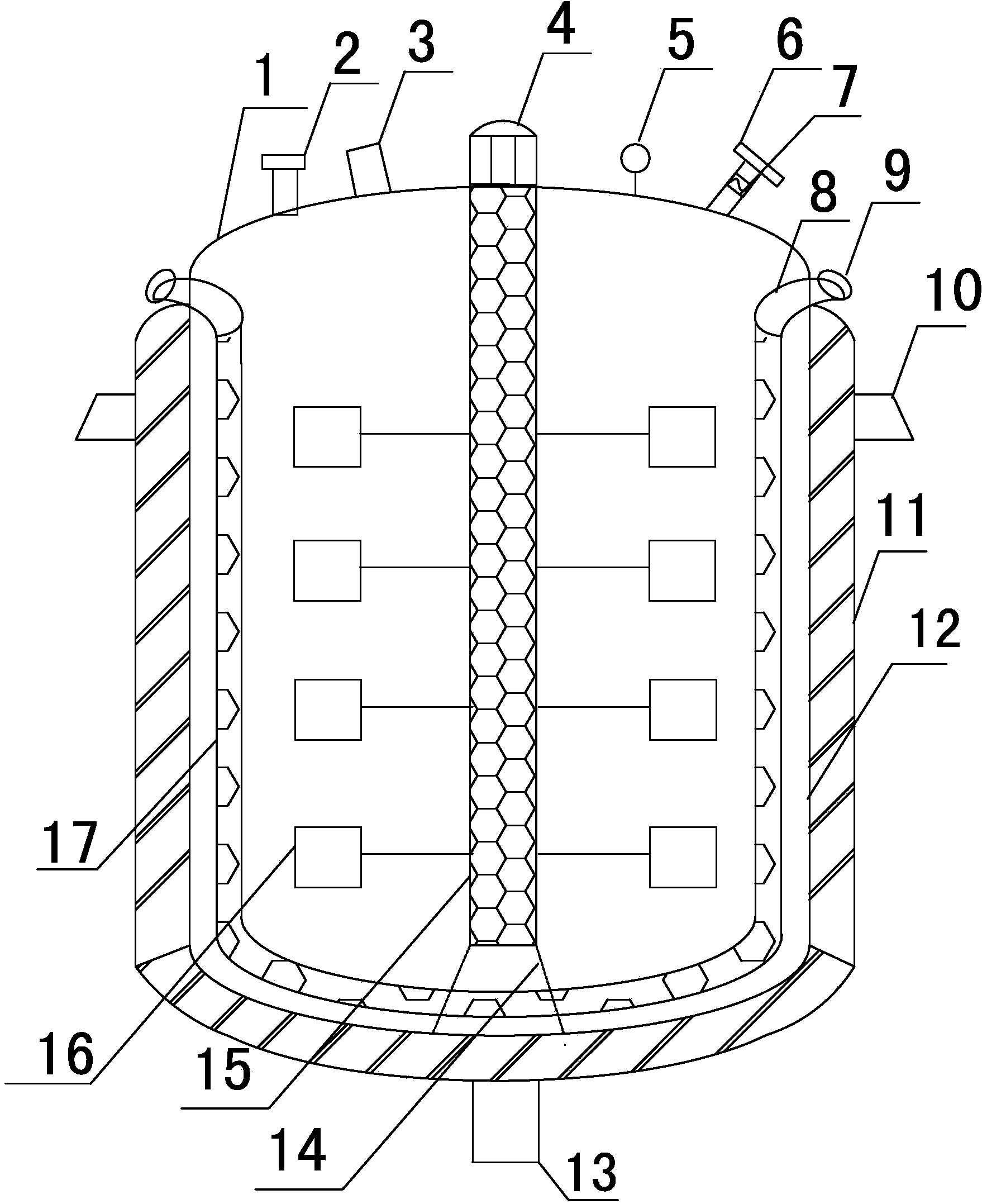

[0019] Such as figure 1 As shown, the pressure-type ACR emulsion polymerization reactor includes an upper head 1, a reactor body 12, a feed port 3 and a discharge port 13, and a motor 4 is arranged on the top of the upper head 1, and the motor 4 Drive the stirring shaft 15 of the stirring device to rotate; the stirring device goes deep into the reactor body 12, and the three-blade back-swept stirring blade 16 is arranged at the end and the middle position of the stirring shaft 15; Pipes 17 and coiled pipes 17 are U-shaped and arranged along the inner wall of the reactor body 12, and the inlet and outlet of the coiled pipes 17 are respectively encapsulated at the junction of the reactor body 12 and the upper head 1 through the oval head 8; A safety valve 6 is provided on the upper part of the head 1, and a burst disc 7 is provided at the entrance of the safety v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com