Special polymer dry-mixed mortar for mechanized construction

A dry-mixed mortar and polymer technology, applied in the field of plastering mortar, can solve the problems of impact resistance, toughness and waterproof and breathable performance not meeting design requirements, affecting construction quality, poor bonding performance, etc., and achieving good and rapid growth. Thickening ability, improve adhesion, increase the effect of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

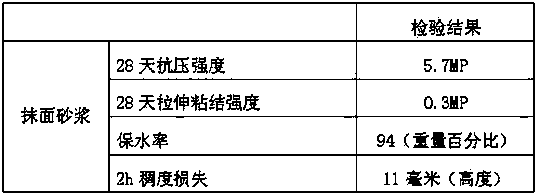

Image

Examples

Embodiment 1

[0014] Component Weight ratio

[0015] Natural sand: 80%

[0016] Cement: 15%

[0017] Fly ash: 5%

[0018] Thixotropic lubricant 0.17%

[0019] Hydroxypropyl Methyl Cellulose HPMC 0.1%

[0020] Polypropylene fiber 0.03%

[0021] 28 days strength 5.5MP

Embodiment 2

[0023] Component Weight ratio

[0024] Natural sand 80%

[0025] Cement 15%

[0026] Fly Ash 5%

[0027] Air-entraining agent 0.035%

[0028] Hydroxypropyl methylcellulose HPMC 0.055%

[0029] Polypropylene fiber 0.003%

[0030] 28 days strength 4.2MP

Embodiment 3

[0032] Component Weight ratio

[0033] Natural sand 78.5%

[0034] Cement 16%

[0035] Fly Ash 5.5%

[0036] Thixotropic lubricant 0.17%

[0037] Hydroxypropyl Methyl Cellulose HPMC 0.1%

[0038] Polypropylene fiber 0.003%

[0039] 28 days strength 9.8MP

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com