Sensitive material used in pressure sensor and preparation method thereof

A pressure sensor and sensitive material technology, applied in the field of nano-sensitive materials, can solve problems such as poor stability, low sensitivity, and inability to make thin materials, and achieve the effect of cheap raw materials, simple process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention provides a sensitive material used in a pressure sensor. The sensitive material is prepared by mixing a carbon material and a volatile solvent in a certain proportion, ultrasonicating, adding a flexible polymer, stirring, and then heating and curing; the carbon The mass ratio of the material to the volatile solvent is 1:1, and the mass ratio of the added flexible polymer to the carbon material is 1:0.5; the prepared sensitive material has a three-dimensional porous structure. Wherein, the flexible polymer is polydimethylsiloxane.

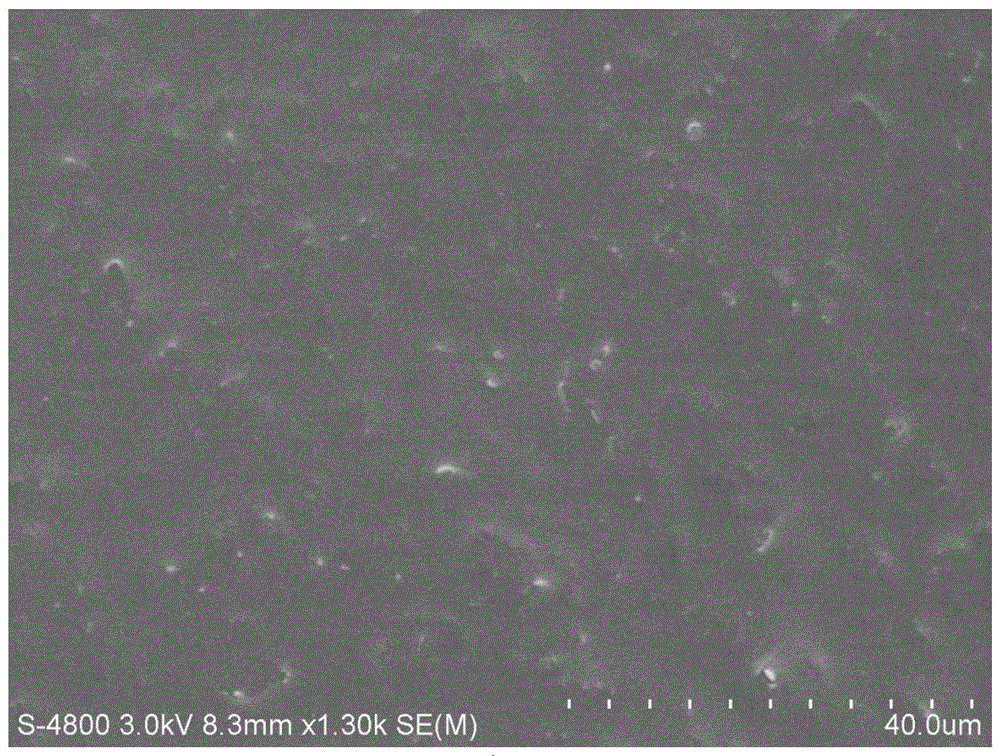

[0035] See figure 1 , figure 1 When the mass ratio between carbon material, volatile solvent and polydimethylsiloxane in the embodiment of the present invention is 1:1:2, the SEM image of the prepared sensitive material with three-dimensional porous structure .

[0036] The carbon material is reduced graphene oxide, and the volatile solvent is ethanol, by figure 1 It can be seen that the size of the pores of the sensitive ma...

Embodiment 2

[0051] The invention provides a sensitive material used in a pressure sensor. The sensitive material is prepared by mixing a carbon material and a volatile solvent in a certain proportion, ultrasonicating, adding a flexible polymer, stirring, and then heating and curing; the carbon The mass ratio of the material to the volatile solvent is 1:2, and the mass ratio of the added flexible polymer to the carbon material is 1:2; the prepared sensitive material has a three-dimensional porous structure. Wherein, the flexible polymer is polydimethylsiloxane.

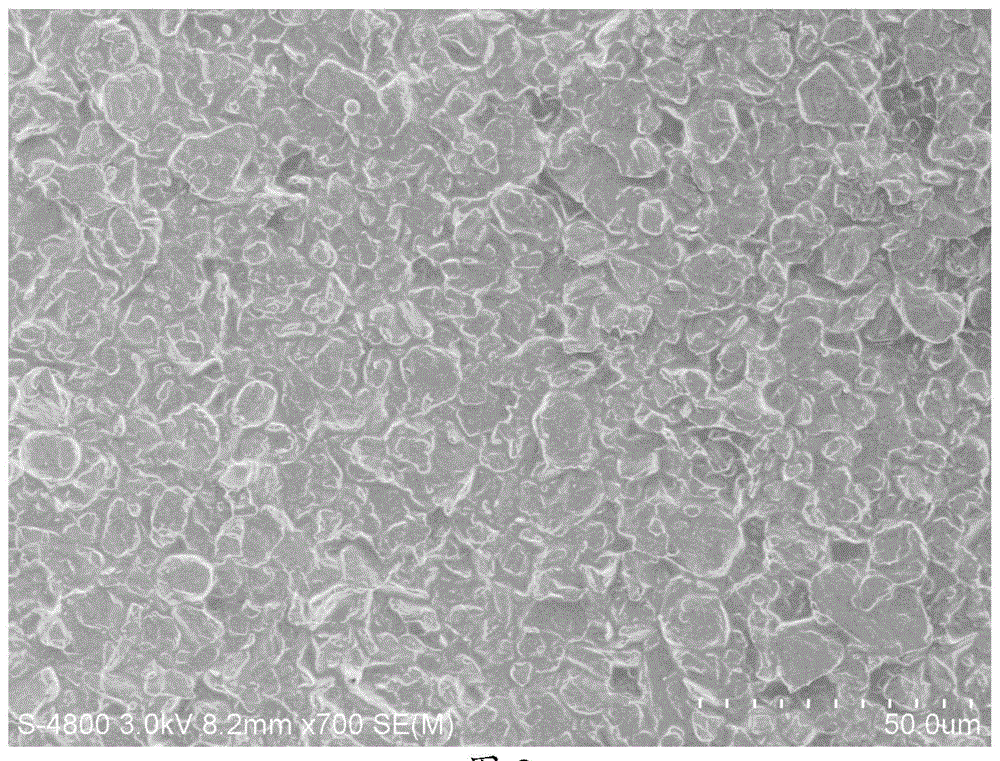

[0052] See figure 2 , figure 2 It is an SEM image of a sensitive material with a three-dimensional pore structure prepared when the mass ratio of the carbon material, the volatile solvent and the flexible polymer in the embodiment of the present invention is 2:4:1.

[0053] The carbon material is reduced graphene oxide, and the volatile solvent is ethanol, by figure 2 It can be seen that the size of the pores of the sensitiv...

Embodiment 3

[0068] The invention provides a sensitive material used in a pressure sensor. The sensitive material is prepared by mixing a carbon material and a volatile solvent in a certain proportion, ultrasonicating, adding a flexible polymer, stirring, and then heating and curing; the carbon The mass ratio of the material to the volatile solvent is 1:3, and the mass ratio of the added flexible polymer to the carbon material is 1:1; the prepared sensitive material has a three-dimensional porous structure. Wherein, the flexible polymer is polydimethylsiloxane.

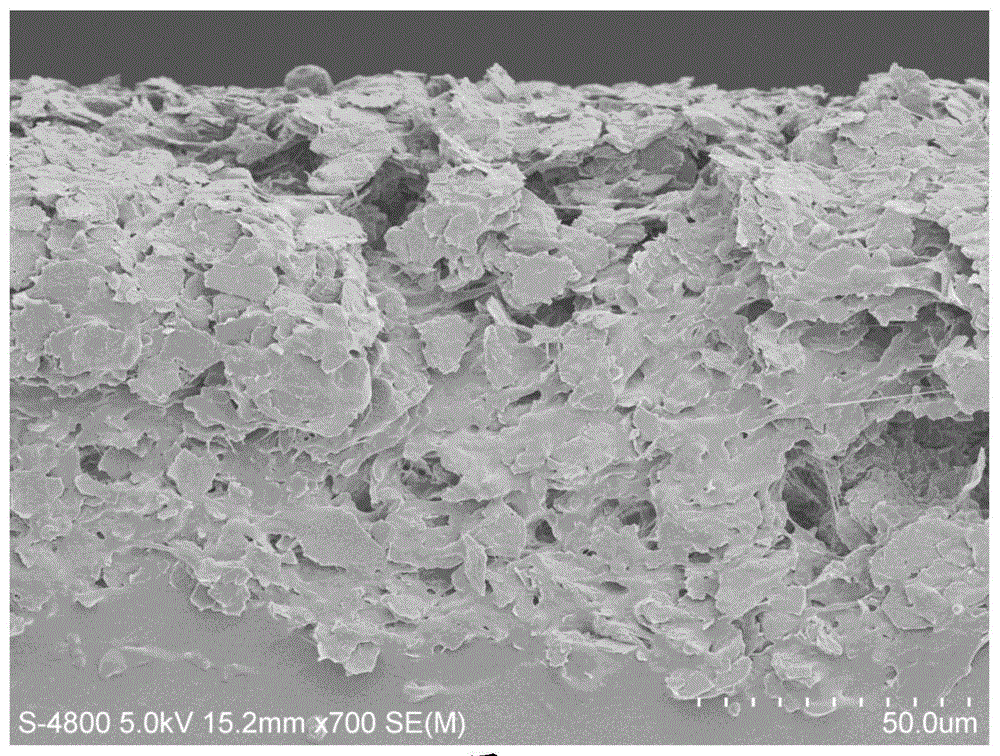

[0069] See image 3 , image 3 It is an SEM image of a sensitive material with a three-dimensional pore structure prepared when the mass ratio of carbon material, volatile solvent and flexible polymer in the embodiment of the present invention is 1:3:1.

[0070] The carbon material is reduced graphene oxide, the volatile solvent is ethanol, the size of the pores of the sensitive material is 7-13 μm, and the gap between the pores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com