Cotton feeding box cotton distributing system

A cotton blending and feeding technology, which is used in fiber feeding, textile and papermaking, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

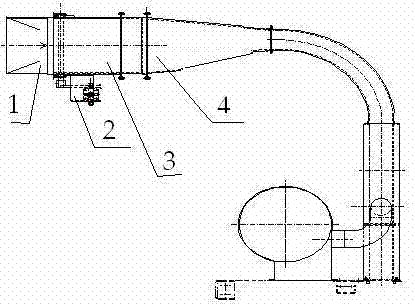

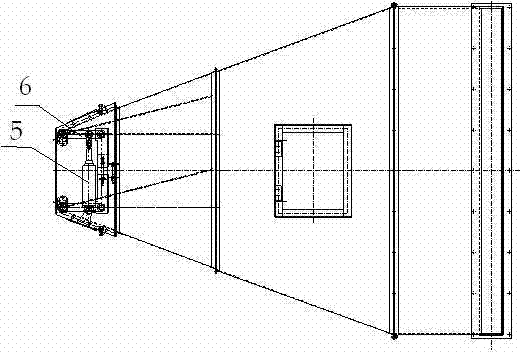

[0011] see Figure 1 to Figure 2 As shown, the present invention is provided with a swing cotton distribution mechanism 2 and a cotton feeding channel 3, a cylinder 5 and a connecting rod 6 are arranged in the swing cotton distribution mechanism 2, and a swingable steel plate is provided on the cotton feeding channel 3, so that The piston of the cylinder 5 is connected with the connecting rod 6, and the connecting rod 6 is provided with an adjustable device. , The connecting rod 6 is connected with the steel plate through a fixing mechanism. The working principle is: fibers and other items enter from the inlet 1 on the top, and the connecting rod 6 connected to it is driven by the action of the cylinder 5. Since the cotton feeding channel 3 is equipped with a swingable steel plate, the connecting rod 6 makes the steel plate swing, thereby forcing Change the wind direction so that the fibers are evenly sent to each position of the cotton box 4. In order to meet the needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com