Polyolefin stretch fiber XLA<TM> and chitosan fiber stretch jean and weaving method thereof

A technology of chitin fiber and elastic fiber, which is used in textiles, papermaking, textiles, fabrics and other directions to achieve the effects of excellent spinnability, excellent wear resistance and good shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The warp is made of polyolefin elastic fiber XLATM and chitin fiber blended yarn with a mixing ratio of 2:98, that is, the polyolefin elastic fiber XLA in the warp TM Accounting for 2% of warp yarn proportion, chitin fiber accounts for 98% of warp yarn proportion; warp yarn adopts 36 / 2X, weft yarn adopts pure cotton 16 / 40D; warp and weft density: 462×271 / 10cm; width: 144 cm. The warp shrinkage of stretch denim ≦ -1.5% and the weft shrinkage ≦ -14.5%.

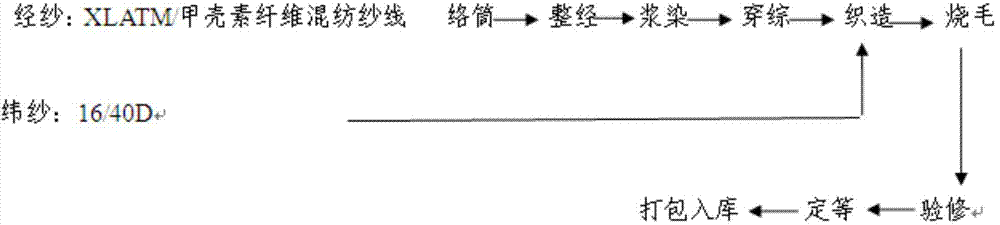

[0026] The weaving method of polyolefin elastic fiber XLATM and chitin fiber (XLATM / chitin fiber) denim in this embodiment, the weaving process is formed by interweaving warp yarn and weft yarn, warp yarn is through winding, warping, sizing dyeing, wearing In the heald, weaving, and gray fabric inspection process, the weft yarn enters the weaving process with the warp yarn after being twisted through the bobbin; the main production process points are:

[0027] In the winding process, the loose winding machine generally a...

Embodiment 2

[0035] The warp yarn is made of polyolefin elastic fiber XLATM and chitin fiber blended yarn with a mixing ratio of 3:97, that is, the polyolefin elastic fiber XLA in the warp yarn TM Accounting for 3% of warp yarn proportion, chitin fiber accounts for 97% of warp yarn proportion, warp yarn adopts 36 / 2X, weft yarn adopts pure cotton 16 / 40D; warp and weft density: 462×271 / 10cm; width: 144 cm. The weaving method is the same as in Example 1. The warp shrinkage of the stretch denim is ≦-1.5%, and the weft shrinkage is ≦-14.5%.

Embodiment 3

[0037] The warp yarn is made of polyolefin elastic fiber XLATM and chitin fiber blended yarn with a mixing ratio of 1:99, that is, the polyolefin elastic fiber XLA in the warp yarn TM Accounting for 1% of warp yarn proportion, chitin fiber accounts for 99% of warp yarn proportion, warp yarn adopts 36 / 2X, weft yarn adopts pure cotton 16 / 40D; warp and weft density: 462×271 / 10cm; width: 144 cm. The weaving method is the same as in Example 1. The warp shrinkage of the stretch denim is ≦-1.5%, and the weft shrinkage is ≦-14.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com