A method for pre-pumping and preventing outburst of strong outburst coal seam

A technology of strong outburst coal seam and pre-extraction is applied in the field of strong outburst coal seam pre-extraction and prevention of outburst, preventing gas outburst accidents in deep coal seams with strong gas outburst, and can solve problems such as gas outburst in holes, gas over-limit accidents, construction difficulties, etc. Achieve the effect of reducing gas content and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

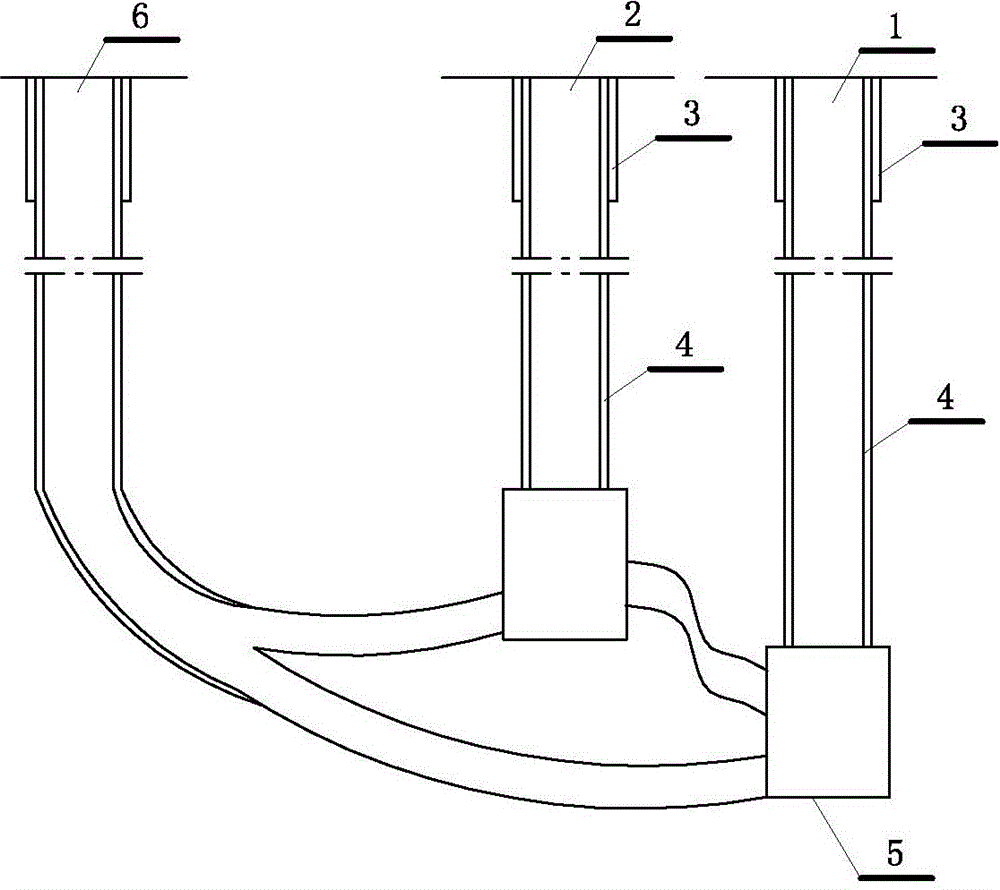

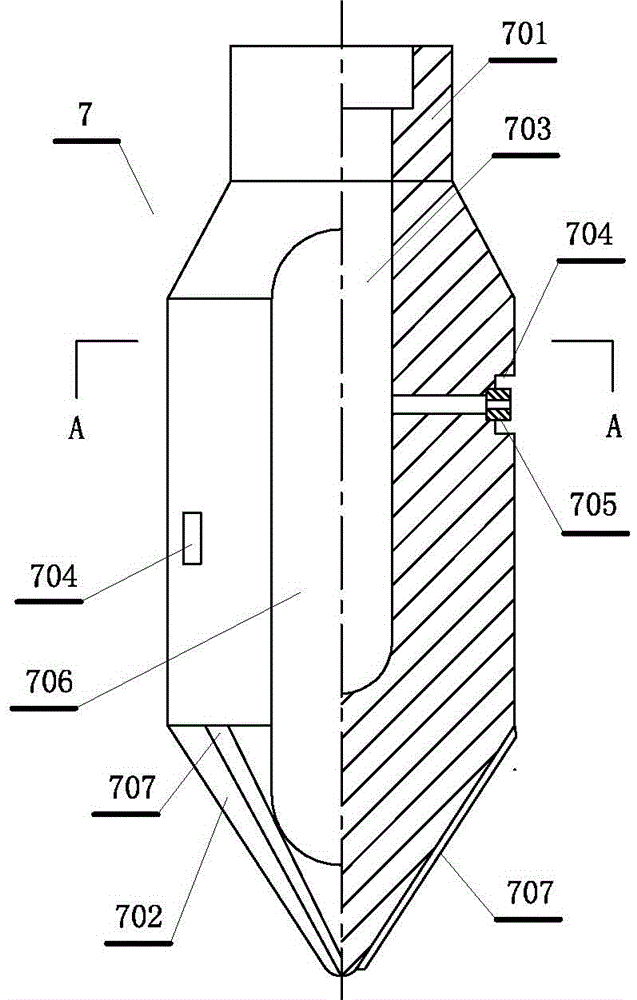

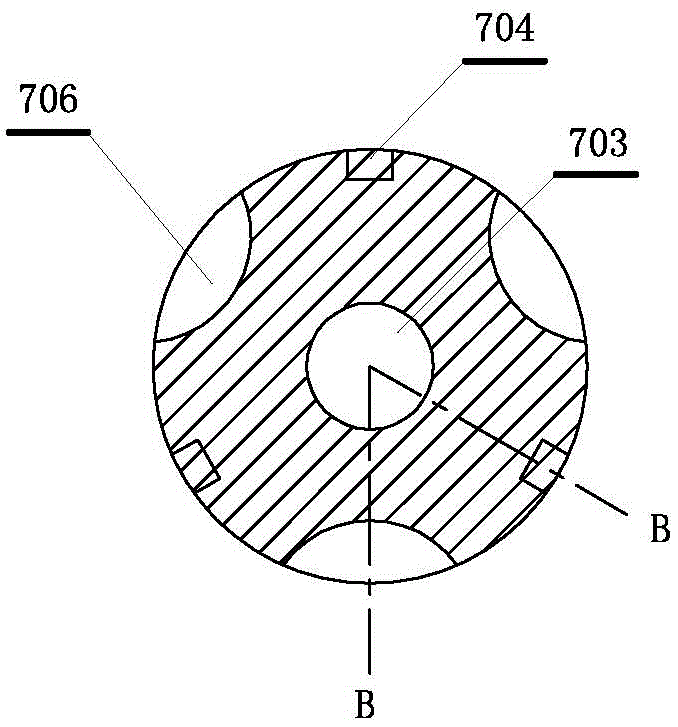

[0018] A method for pre-extraction and anti-outburst of strong outburst coal seams. After exploration in the coal mine area, there is a high-gas coal seam mining area that has been determined. First, within the edge of the mining area, drill down along the direction of the roadway to be excavated within a range of no more than 15 meters from the ground. Two shafts, respectively the first shaft and the second shaft, the diameter of the two shafts after cementing is between 150mm and 200mm, the bottom of the two shafts extends into the coal seam at least 10 meters, from 1 meter away from the coal seam to the wellhead The side wall is cemented with cement; the coal seam hole is mechanically reamed to at least 4 times the diameter of the vertical shaft, and then a reaming high-pressure water jet drill bit is inserted into the coal seam at the bottom of the well, and the high-pressure water jet reaming process is used to continue to expand the two holes. The coal seam holes under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com