Surface modified stainless steel cathode for electrolyser

A stainless steel, electrolyzer technology, applied in electrodes, electrode coatings, electrolysis components, etc., can solve the problem of difficulty in obtaining carbon steel coated cathodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Micro slot test:

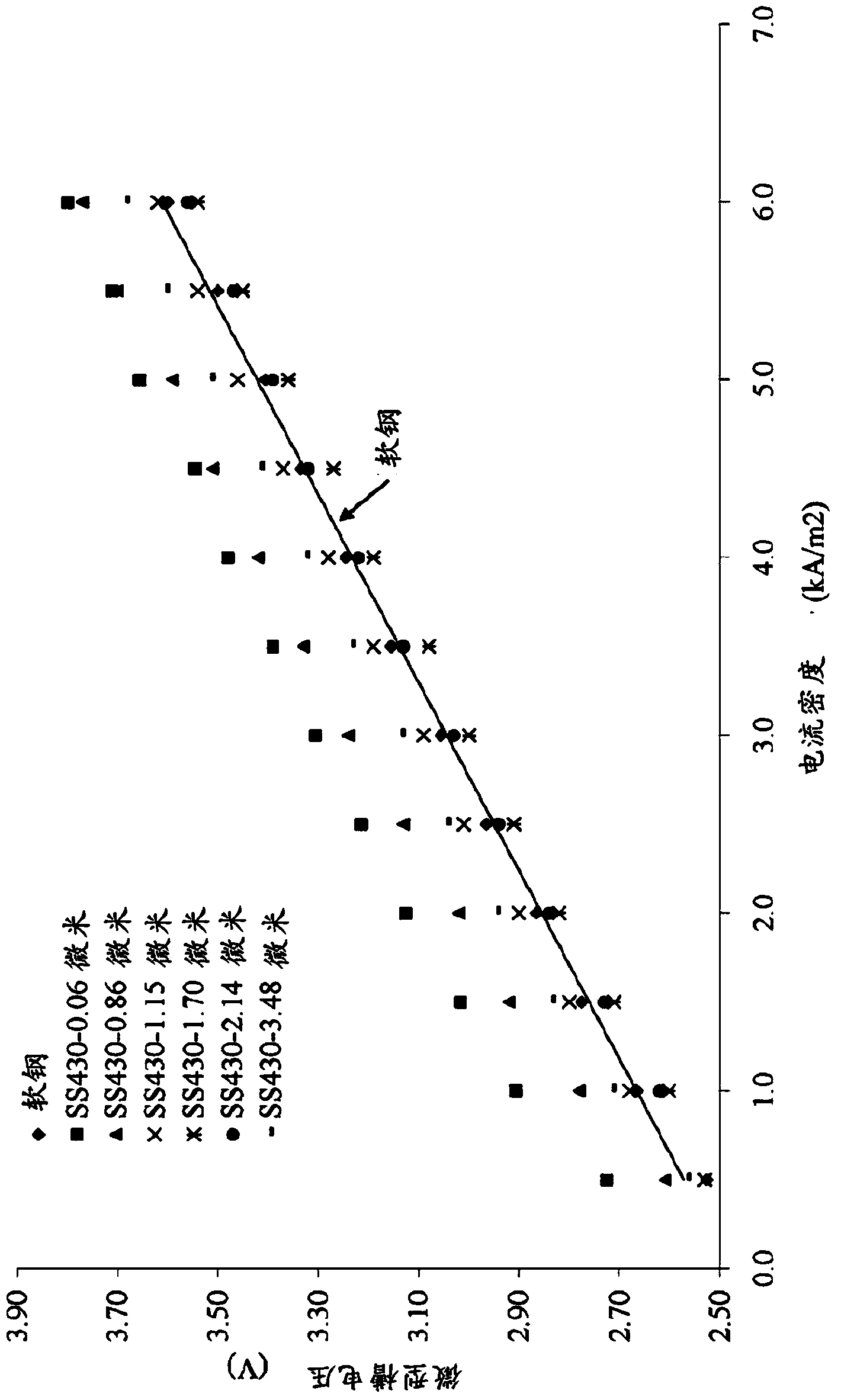

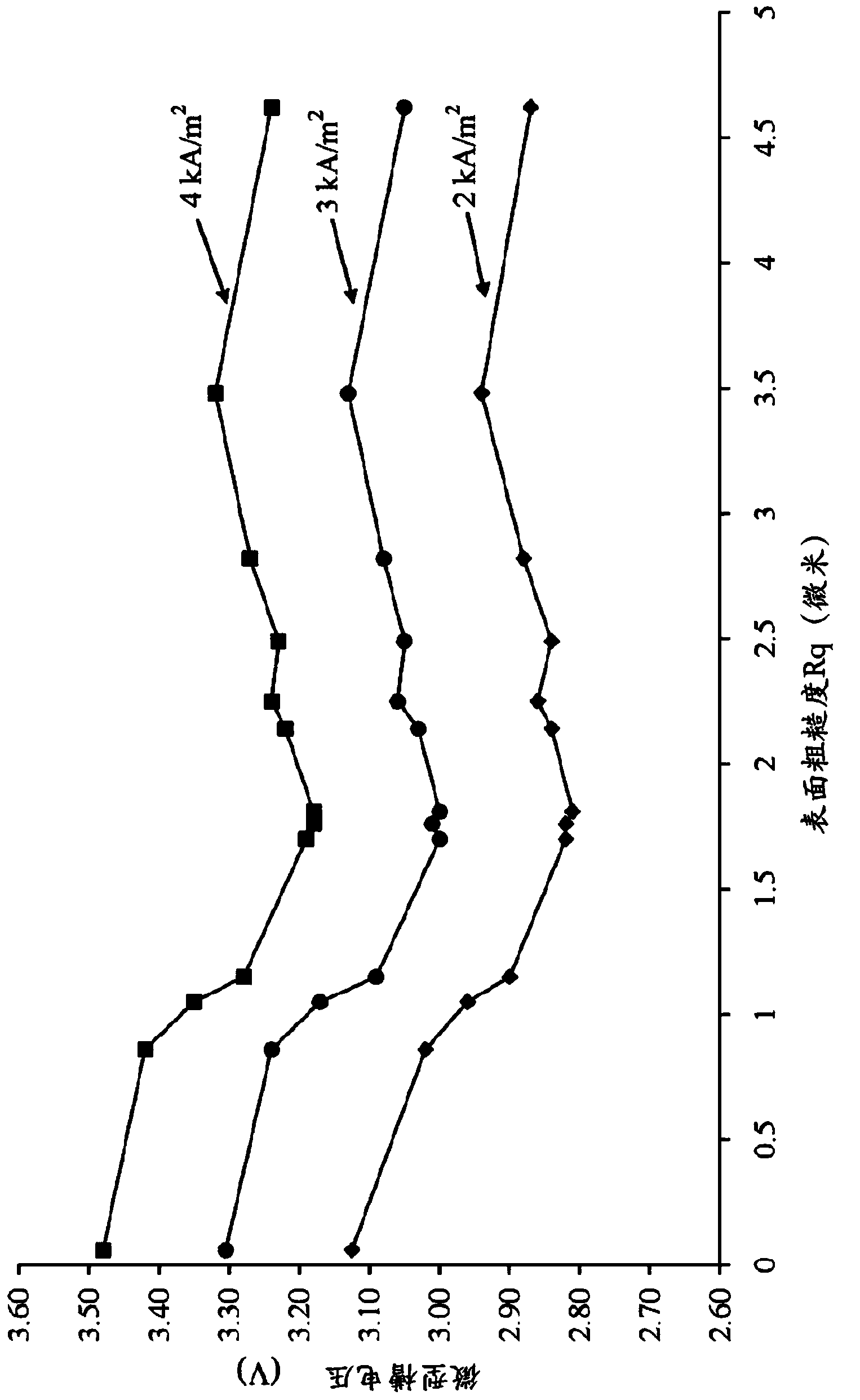

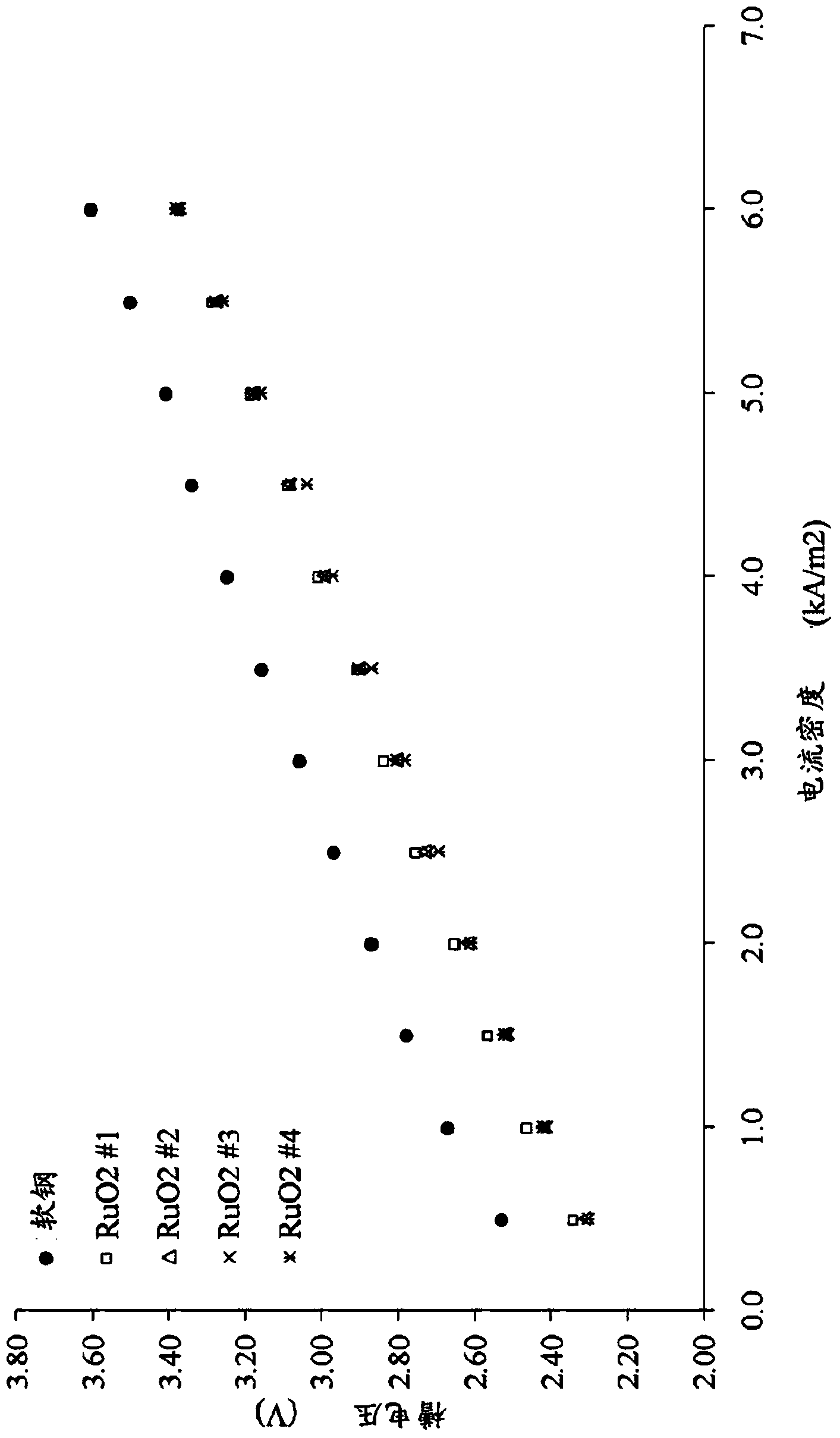

[0045] A series of cathode material samples were tested in laboratory microcells under static conditions, but otherwise similar to those experienced in commercial chlorate electrolyzers. Micro-cell construction using a sample of cathode material as the cell cathode and using an adjusted as a cell anode. Both electrodes are flat sheets. Active test surface area is 2cm 2 And the gap between them is 5.8mm. The electrolyte is NaClO with a concentration of 450 / 115 / 5gpl 3 / NaCl / Na 2 Cr 2 o 7 of aqueous solution. These electrodes were immersed in an electrolyte solution at a test temperature of 80°C. Unlike commercial electrolyzers, the electrolyte was not circulated and there was no continuous supply of brine feed during the test.

[0046]Where indicated, various cathode material samples were surface-modified and their roughness was measured prior to assembly into microchannels. Fresh electrolyte is then added, heated to the test temperature, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com